Method for avoiding forming hydrogen sulfide hydrate in carbon bisulfide production process

A carbon disulfide, production process technology, applied in the direction of carbon disulfide, carbon-sulfur compounds, etc., can solve the problems of many water leakage points, time-consuming and laborious search, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

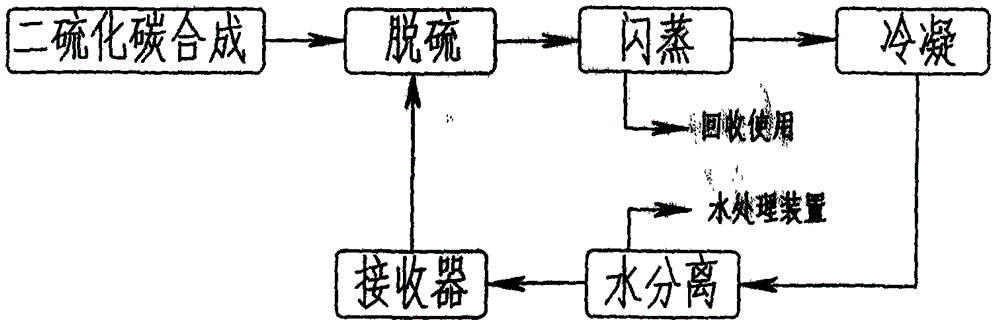

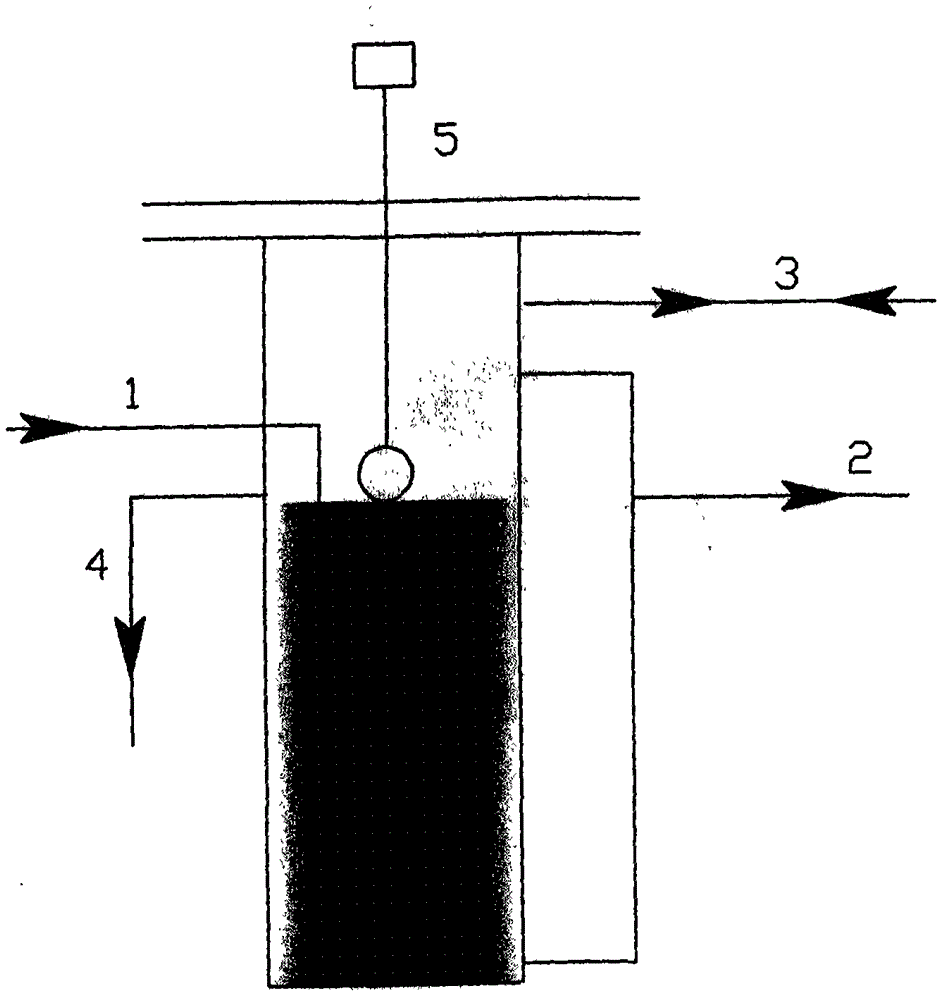

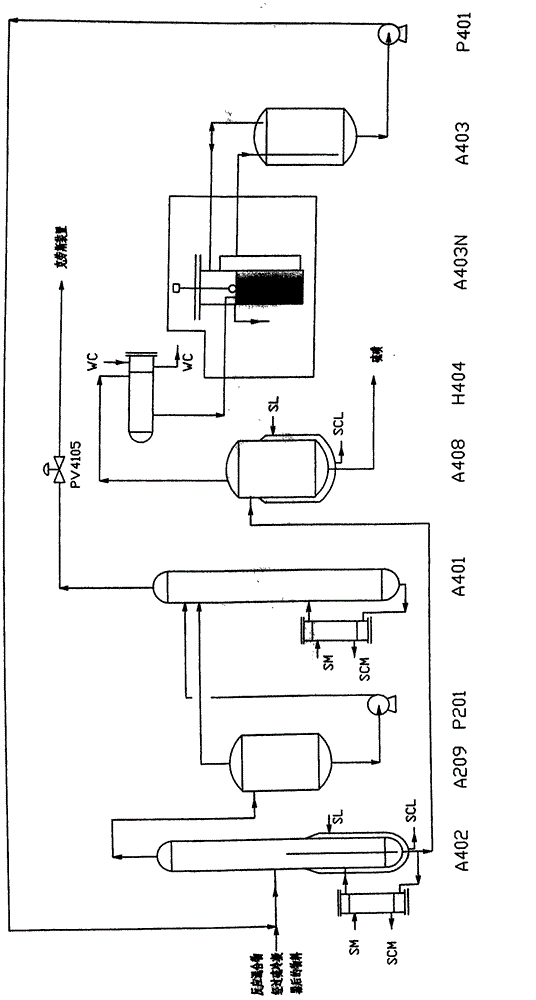

[0033] refer to figure 2 and 3 As shown, the product obtained from the reaction of natural gas with methane and ethane as the main components and sulfur after passing through the condenser A206 enters the flash tank A408 together with the bottom product of the uncondensed product entering the desulfurization tower A402 , for the separation of carbon disulfide and sulfur. The tank top product is a mixed gas of carbon disulfide and a small amount of hydrogen sulfide. The mixed gas enters the flash carbon disulfide condenser H404, and all the gas is cooled to liquid and enters the water separation device A403N. If there is water leaking into the device, the carbon disulfide Layered with water, the water layer is in the upper part, because the density of water is lower than that of carbon disulfide, so the liquid level displayed by the liquid level switch 5 increases, and the liquid level switch will automatically alarm when it reaches the set value. The valve discharges the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com