Continuous carbon disulfide production process and device adopting coke method

A technology of carbon disulfide and production process, which is applied in the direction of carbon disulfide, carbon sulfur compounds, energy input, etc., can solve problems such as environmental and safety hazards, achieve high production efficiency and improve the production environment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

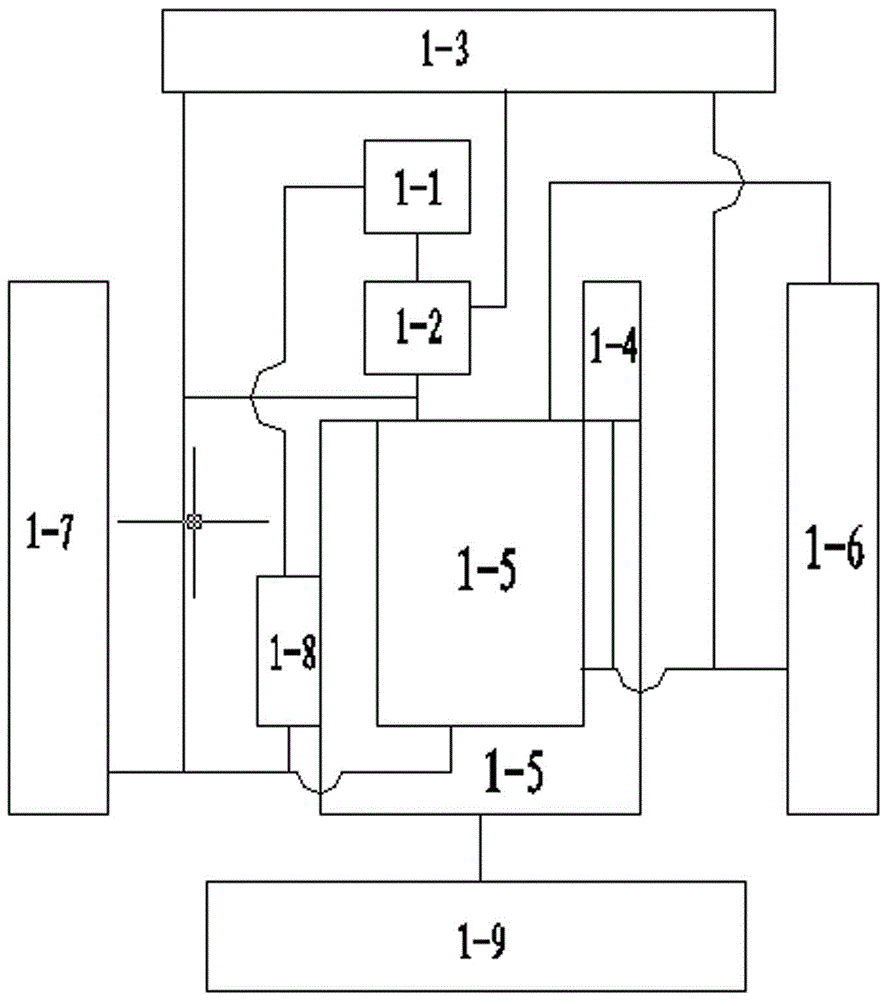

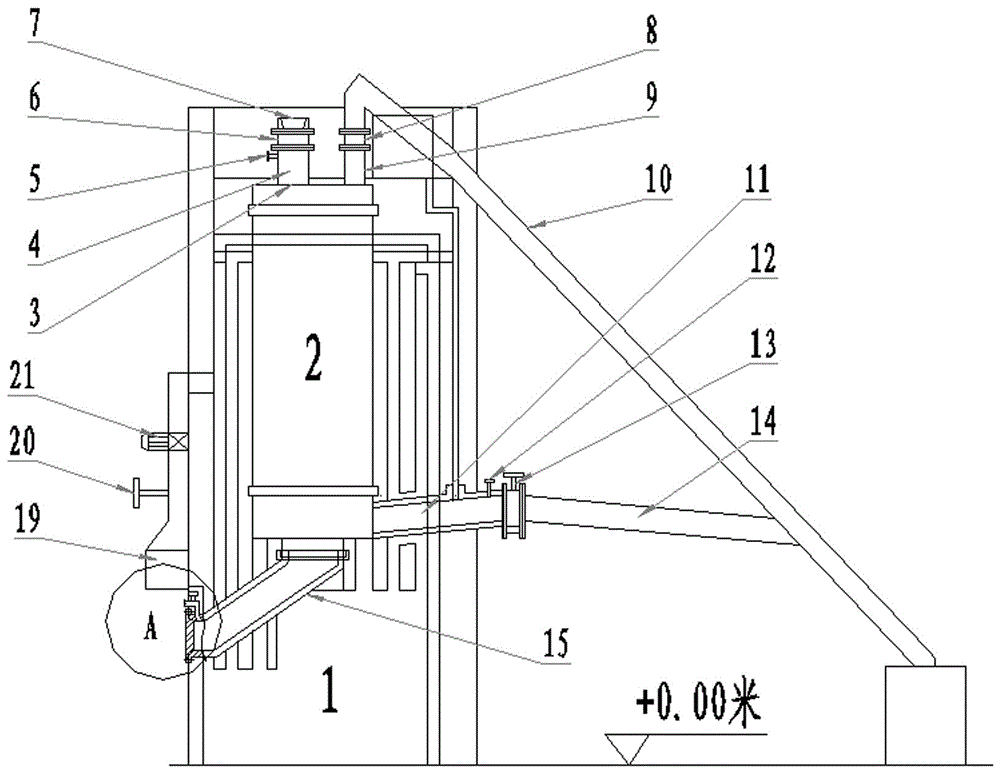

[0035] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

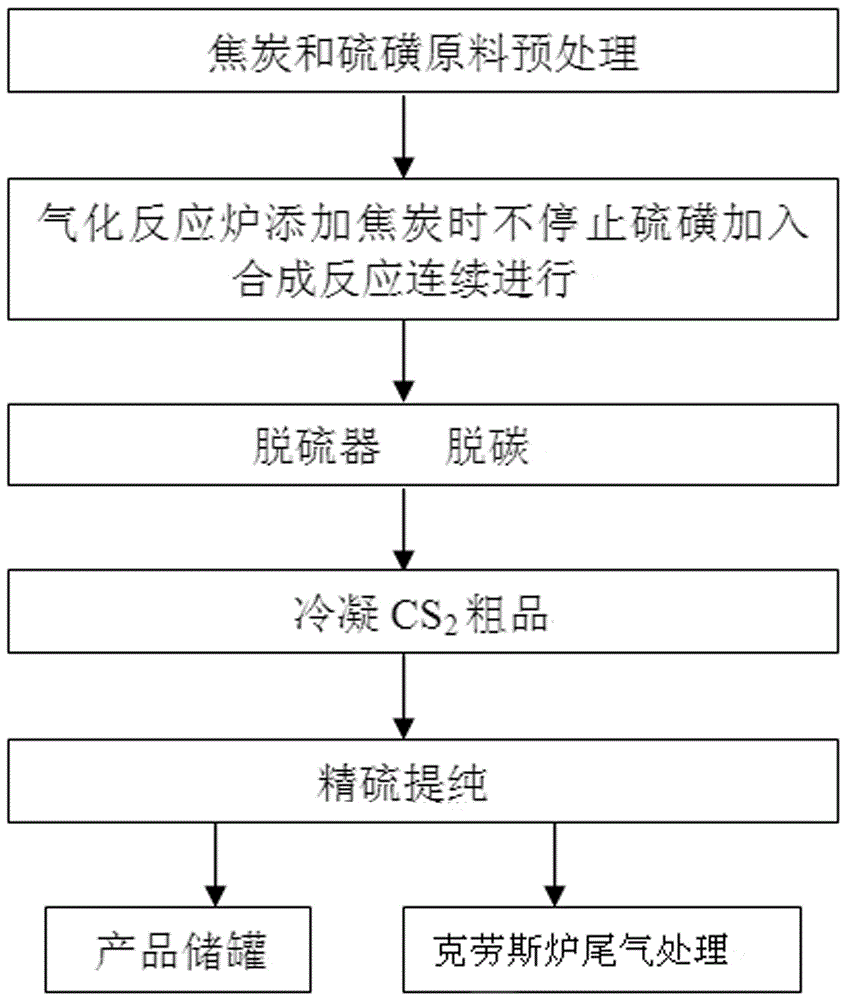

[0036] Such as figure 2 As shown, the continuous production process of carbon disulfide coke method includes: raw material pretreatment (carbon drying and sulfur melting) - synthesis reaction - desulfurization - condensation - rectification purification - Claus furnace tail gas treatment, in which desulfurization, condensation, Rectification purification and Claus furnace tail gas treatment are all completed by CS2 recovery system.

[0037] The addition of coke raw materials in the reaction furnace in the synthesis reaction process is an airtight feeding method. When the slag is removed from the reaction furnace, the gas distributed with the slag is concentrated and cleanly discharged. The coke raw material in the reaction furnace in the synthesis reaction process is added. The special feeding bin of the chemical reaction furnace is filled with red coke, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com