Device and method for simultaneously producing ultra-high-purity carbon oxysulfide and high-purity carbon disulfide

A carbon disulfide, carbon oxysulfide technology, applied in the direction of carbon disulfide, carbon oxysulfide, carbon-sulfur compounds, etc., can solve the problems of impure technology, complex process and unadvanced raw material gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

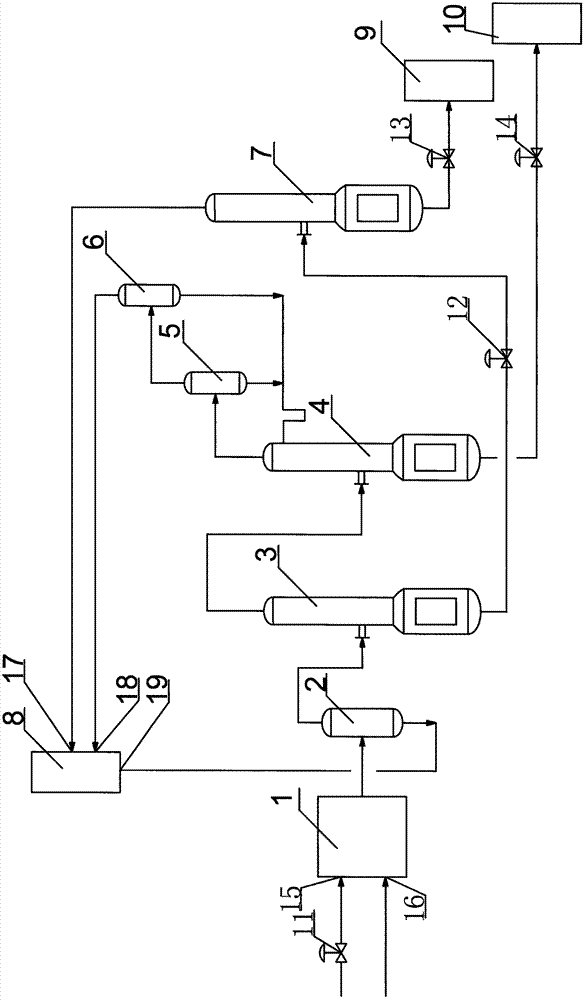

[0041] A method for simultaneously producing ultra-high-purity carbon oxysulfide and high-purity carbon disulfide, the method comprising the steps of:

[0042] Step 1: The carbon monoxide raw material gas enters the reactor 1 through the first regulating valve 11 and the first raw material inlet 15 of the reactor 1; the sulfur raw material enters the reactor 1 through the sulfur raw material pipeline and the second raw material inlet 16 of the reactor 1; The carbon monoxide raw material gas is a high-purity raw material gas, and the composition of the high-purity raw material gas is: the molar volume fraction of CO ≥ 99.5%, and the rest are inert gases, wherein H 2 O≤5ppm, the temperature is normal temperature, and the pressure is: 0.5Mpa; the sulfur raw material is Claus reaction to generate solid sulfur;

[0043] Step 2: The two raw materials entering the reactor 1 described in step 1 are synthesized under the conditions of catalyst and heating. Main reaction: CO+S=COS, side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com