Recycling utilization method of oil refinery sulfur removal plant sulfur vapor

A technology of sulfur steam and oil refinery, which is applied in the field of recycling and utilization of sulfur steam in the desulfurization workshop of the oil refinery, can solve the problems of non-conformity with the project approval principles of chemical products, negative effects of global warming, environmental pollution, etc., and achieve saving of equipment and storage Freight, low cost, high benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

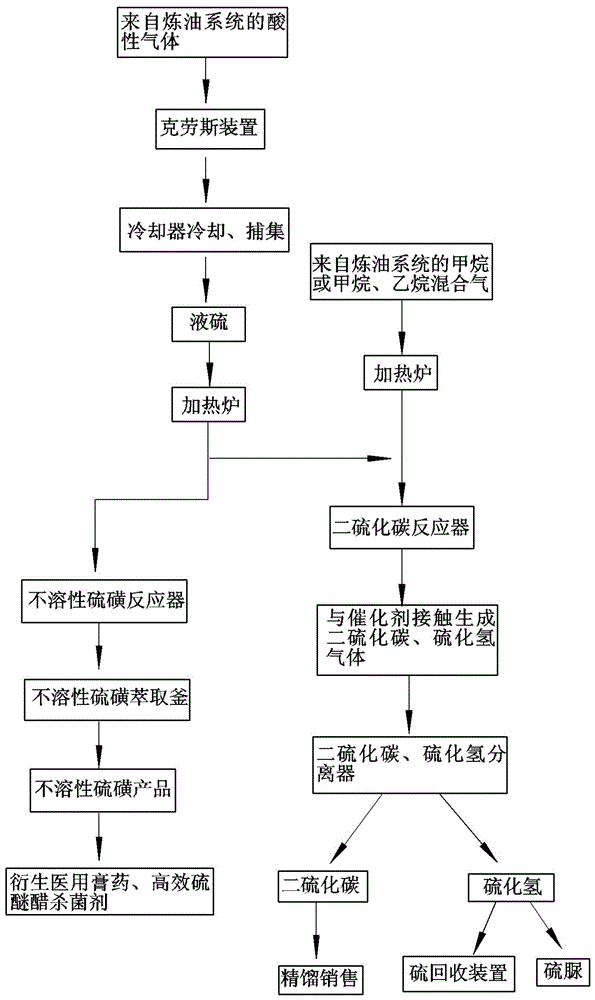

[0023] Example 1: A method for recycling sulfur steam in the desulfurization workshop of an oil refinery. First, the acid gas from the oil refining system is sent to the Claus unit for sulfur recovery. ℃-500℃ mixed gas, the time for the acid gas to pass through the Claus device is very short, roughly 0.01-0.5s. The acid gas is a compound gas, including hydrogen sulfide, sulfur dioxide, chlorine, hydrogen chloride gas, carbon dioxide, nitrogen monoxide, etc., wherein the ratio of hydrogen sulfide, sulfur dioxide, chlorine gas, hydrogen chloride, carbon dioxide, and nitrogen monoxide gas is: 77.63: 11.76:2.36:1.19:4.22:2.84.

[0024] The mixed gas is cooled by the cooler and captured by the trap to obtain liquid sulfur at 160-165°C. The cooling temperature of the cooler is selected at 160-165°C; then the liquid sulfur is directly sent to the heating furnace, and the heating furnace is heated to Sulfur vapor is formed at 500-600°C, and then the mixed gas of methane and ethane fr...

Embodiment 2

[0030] Example 2: A method for recycling sulfur steam in the desulfurization workshop of an oil refinery. First, the acid gas from the oil refining system is sent to the Claus unit for sulfur recovery. ℃-500℃ mixed gas, in which the acid gas is a compound gas, including hydrogen sulfide, sulfur dioxide, chlorine gas, hydrogen chloride gas, carbon dioxide, nitric oxide, etc. The mixed gas is cooled by a cooler and captured by a trap to obtain liquid sulfur at 165-170°C; then the liquid sulfur is directly sent to the heating furnace, and the furnace is heated to 600-700°C to form sulfur vapor, and then the sulfur vapor from the oil refining The methane in the system is also heated to 600-700°C by the heating furnace.

[0031] The sulfur vapor heated to 600-700°C in the heating furnace is divided into two paths: one path of sulfur vapor is directly sprayed into the insoluble sulfur reactor, quenched in a carbon disulfide solution containing a composite stabilizer, and crushed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com