Recovery and utilization method of sulfur steam in desulfurization workshop of refinery

A technology of sulfur steam and oil refinery, which is applied in the field of sulfur steam recovery and utilization in desulfurization workshops of oil refineries, can solve problems such as non-compliance with the principles of chemical product project establishment, negative effects of global warming, equipment corrosion, etc., to save equipment and storage. The effect of freight, low cost, and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

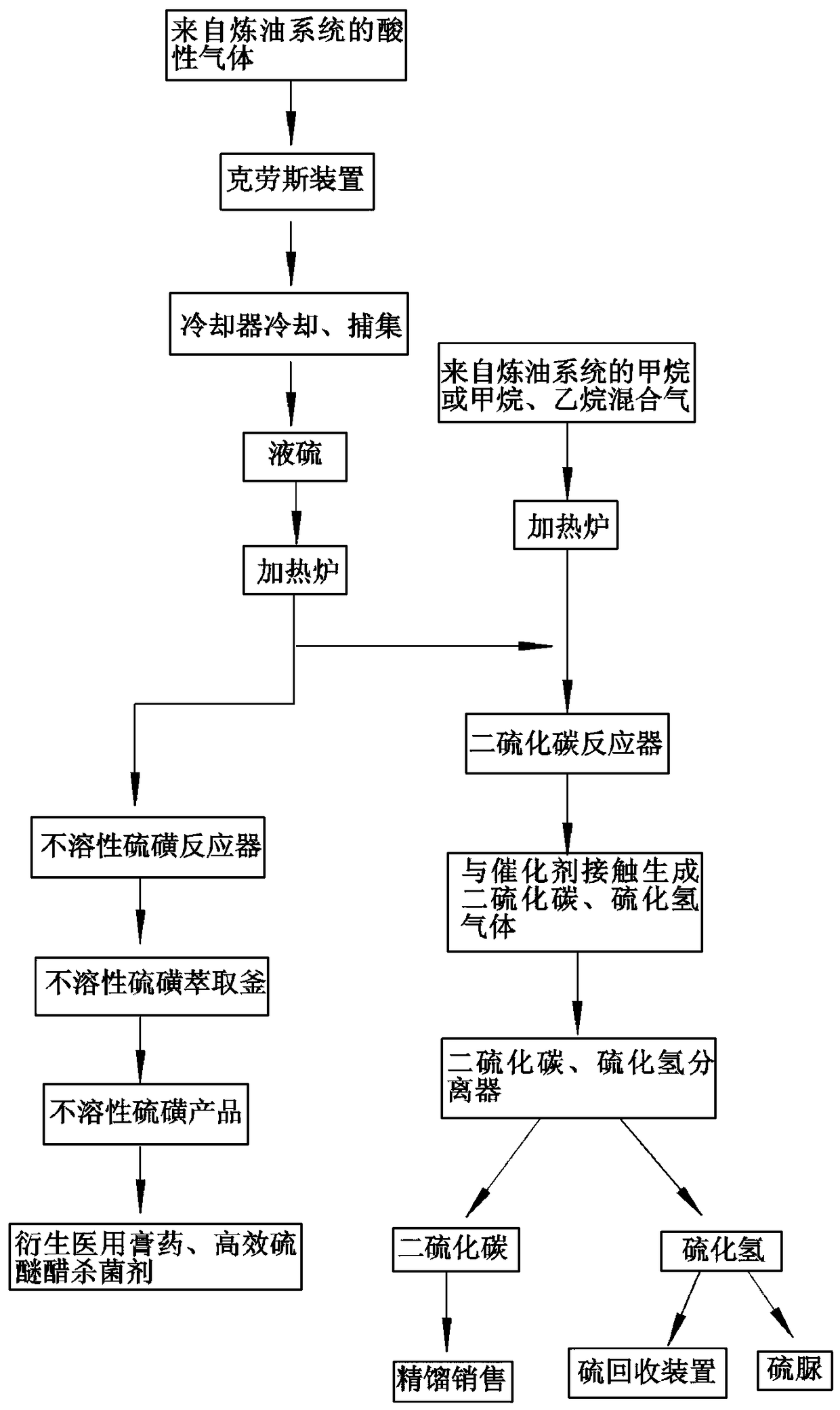

[0023] Example 1: A method for the recovery and utilization of sulfur steam in the desulfurization workshop of an oil refinery. Firstly, the acid gas from the refinery system is sent to the Claus device for sulfur recovery, and after treatment at 1100-1200°C, the waste heat boiler obtains 300 For mixed gas of ℃-500℃, the time for acid gas to pass through the Claus device is very short, about 0.01-0.5s. Among them, acid gas is a composite gas, including hydrogen sulfide, sulfur dioxide, chlorine, hydrogen chloride gas, carbon dioxide, nitrogen monoxide, etc. The ratio of hydrogen sulfide, sulfur dioxide, chlorine, hydrogen chloride and carbon dioxide to nitrogen monoxide is 77.63: 11.76:2.36:1.19:4.22: 2.84.

[0024] The mixed gas is cooled by a cooler and trapped to obtain liquid sulfur at 160-165°C. The cooling temperature of the cooler is selected at 160-165°C; then the liquid sulfur is directly sent to the heating furnace, and the heating furnace is heated to Sulfur steam is ...

Embodiment 2

[0030] Example 2: A method for the recovery and utilization of sulfur steam in the desulfurization workshop of an oil refinery. First, the acid gas from the refinery system is sent to the Claus device for sulfur recovery, and after treatment at 1200-1300°C, the waste heat boiler obtains 300 ℃-500 ℃ mixed gas, of which acid gas is a composite gas, including hydrogen sulfide, sulfur dioxide, chlorine, hydrogen chloride gas, carbon dioxide, nitrogen monoxide, etc. The mixed gas is cooled by a cooler and trapped by a trap to obtain liquid sulfur at 165-170°C; then the liquid sulfur is directly sent to the heating furnace, and the heating furnace is heated to 600-700°C to form sulfur vapor, which is then extracted from the oil refinery The methane in the system is also heated to 600-700°C by the heating furnace.

[0031] The sulfur vapor heated to 600-700℃ in the heating furnace is divided into two ways: one sulfur vapor is directly injected into the insoluble sulfur reactor, quenched...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com