Waste gas recovery system for mucilage glue production

A waste gas recovery and viscose technology, which is applied in the separation of dispersed particles, carbon disulfide, chemical instruments and methods, etc., can solve the problems of atmospheric and environmental pollution, inability to effectively treat waste gas, and direct discharge of waste gas failing to meet the emission standards, and achieve collection Good effect and low cost investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

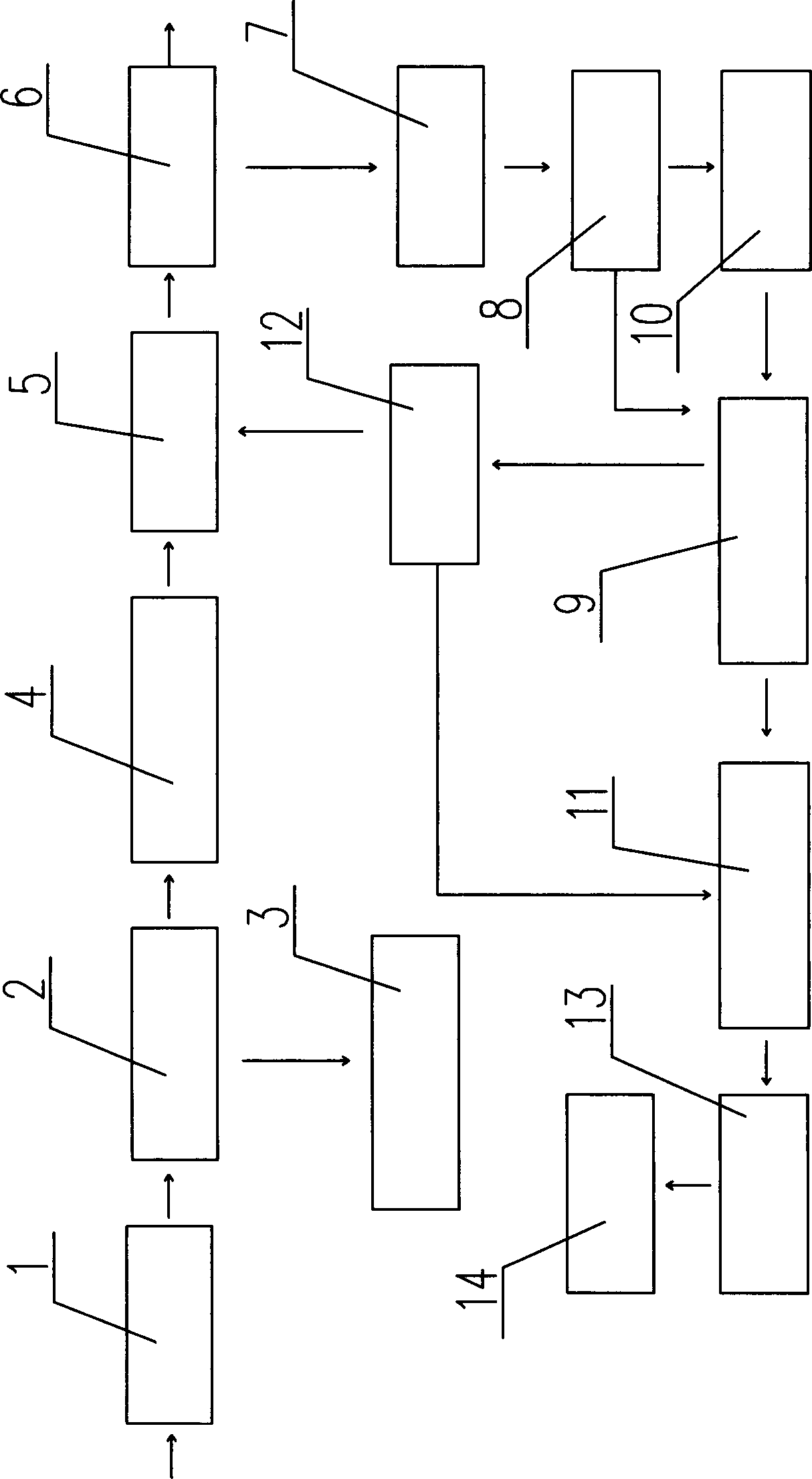

[0008] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0009] Such as figure 1 As shown, the viscose production exhaust gas recovery system includes: alkali washing blower 1, the alkali washing tank 2 connected with the alkali washing blower 1, the Na 2 S, NaHS storage tank 3 and washing tower 4, the blower fan 5 that is connected with described washing tower 4, the activated carbon adsorption tank 6 that is connected with described blower fan 5, the evaporator 7 that is connected with described activated carbon adsorption tank 6, The first condenser 8 that is connected with the evaporator 7, the gas-liquid separator 9 and the second condenser 10 that are connected with the first condenser 8, the specific gravity that is connected with the gas-liquid separator 9 Separator 11 and safety tank 12, the aftercooler 13 connected with the specific gravity separator 11 and the CS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com