Treatment technology and equipment for carbon disulfide production process gas

A production process, carbon disulfide technology, applied in the field of sulfur industry, can solve problems such as difficult control of catalytic conversion temperature, and achieve the effect of solving the problem of difficult control of catalytic conversion temperature and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

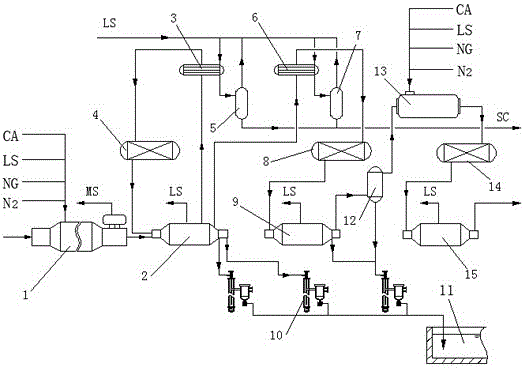

[0037] A process gas treatment process for the production of carbon disulfide, which divides the process gas treatment into two stages: oxidation catalytic recovery and hydrogenation catalytic reduction. The sour gas combustion furnace 1 is combusted with natural gas NG and compressed air CA at 950°C, and 80% of the air volume is controlled by the complete combustion of hydrocarbons and 1 / 3 of hydrogen sulfide to generate sulfur dioxide. 2 S: SO 2= 2:1 to control the remaining 20% of the air volume. The high-temperature process gas after combustion enters the steam generation system of the acid gas combustion furnace, and produces 2.2MPa medium-pressure steam MS by-product, which is cooled to 350°C after heat exchange. The process gas enters the first-stage condensing cooler 2, and produces 0.35Mpa low-pressure steam LS in the first-stage condensing cooler 2. At the same time, the process gas itself is cooled to 160°C, and the condensed liquid sulfur is sealed from the outl...

Embodiment 2

[0040] A treatment process for producing process gas from carbon disulfide, as attached figure 1 As shown, the treatment of process gas is divided into two stages: oxidation catalytic recovery and hydrogenation catalytic reduction. , Air CA burns at 1000°C, 80% of the air volume is controlled by the complete combustion of hydrocarbons and 1 / 3 of hydrogen sulfide to generate sulfur dioxide, and according to the H in the tail gas 2 S: SO 2 = 2:1 to control the remaining 20% of the air volume. The high-temperature process gas after combustion enters the steam generation system of the acid gas combustion furnace, and produces 2.2MPa medium-pressure steam by-product, which is cooled to 350°C after heat exchange. The process gas enters the first-stage condensing cooler 2, and produces 0.35Mpa low-pressure steam in the first-stage condensing cooler 2. At the same time, the process gas itself is cooled to 160°C, and the condensed liquid sulfur is discharged from the outlet of the...

Embodiment 3

[0043] A process gas treatment process for the production of carbon disulfide, which divides the process gas treatment into two stages: oxidation catalytic recovery and hydrogenation catalytic reduction. The sour gas combustion furnace 1 is combusted with natural gas NG and air CA at 1000°C, and 80% of the air volume is controlled by the complete combustion of hydrocarbons and 1 / 3 of hydrogen sulfide to generate sulfur dioxide. 2 S: SO 2 = 2:1 to control the remaining 20% of the air volume. The high-temperature process gas after combustion enters the steam generation system of the acid gas combustion furnace, and produces 2.2MPa medium-pressure steam by-product, which is cooled to 350°C after heat exchange. The process gas enters the first-stage condensing cooler 2, and produces 0.35Mpa low-pressure steam in the first-stage condensing cooler 2. At the same time, the process gas itself is cooled to 160°C, and the condensed liquid sulfur is discharged from the outlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com