Full polished glaze porcelain tile capable of self-exciting to produce negative ions, and preparation method for full polished glaze porcelain tile

A manufacturing method and negative ion technology, which is applied in the field of fully polished glazed porcelain tiles, can solve the problems of lack of high-quality porcelain tiles, and achieve low porosity, obvious effect, and good antifouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

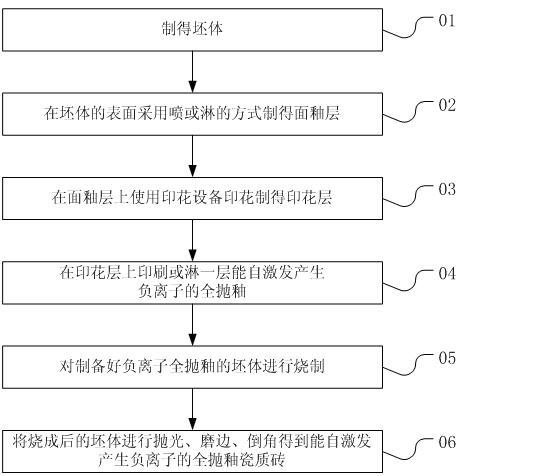

[0068] In the present invention, the preparation methods of the full polished glaze are also different under different construction modes. Wherein the preparation method of the negative ion full-glaze glaze that adopts the method for pouring glaze to use is:

[0069] Step a, after weighing the negative ion material and batching, add the full polish glaze and mix;

[0070] Step b, ball milling the full cast glaze added with negative ion material;

[0071] Step c, detecting the fineness of the fully polished glaze after ball milling;

[0072] Step d, sieving the ball-milled full-throw glaze;

[0073] Step e, removing iron from the sieved full polish glaze to obtain negative ion full polish glaze.

[0074] Among them, the ball mill uses water as the medium, and its ratio is glaze: water=100:110~130.

[0075] Wherein the preparation method of the negative ion full polishing glaze that adopts the printing method to use is:

[0076] Step a', after weighing and proportioning the...

Embodiment 1

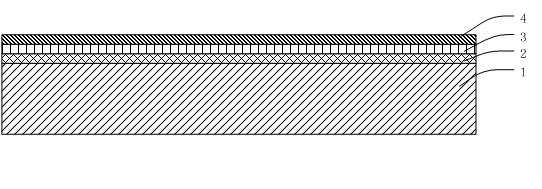

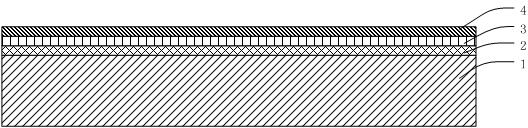

[0085] The production technology of described negative ion porcelain glazed tile, its steps are as follows:

[0086] ⑴Debugging the combined green body formula to prepare bricks with a size of 600×600mm;

[0087] ⑵Use a press to press the debugged and combined green body powder into bricks of the required specifications, and the pressing pressure is 29.5Mpa;

[0088] (3) Dry the compacted body at 160°C for 60 minutes;

[0089] (4) Spray glaze on the surface of the dried body, and the amount of glaze applied to the 600×600mm brick is 54g / 30×30cm pallet;

[0090] ⑸Using printing equipment to print on the glaze;

[0091] ⑹Print a layer of negative ion full glaze on the surface of the green body after printing, and the usage amount is 180g / 600×600mm brick;

[0092] ⑺Firing the glazed green body at a temperature of 1190°C for 60 minutes;

[0093] ⑻ Polish, grind and chamfer the fired body to obtain negative ion full-glazed porcelain tiles.

[0094] The specific gravity of the ...

Embodiment 2

[0109] The production technology of described negative ion porcelain glazed tile, its steps are as follows:

[0110] ⑴Debugging the combined green body formula to prepare bricks with a size of 600×600mm;

[0111] ⑵Use a press to press the debugged and combined green body powder into bricks of the required specifications, and the pressing pressure is 30.5Mpa;

[0112] (3) Dry the compacted body at 200°C for 40 minutes;

[0113] (4) Spray glaze on the surface of the dried body, and the amount of glaze applied to the 600×600mm brick is 60g / 30×30cm pallet;

[0114] ⑸ Sprinkle a layer of negative ion full glaze on the surface of the green body, the usage amount is 220g / 600×600mm brick;

[0115] (6) Fire the body after glazing at a temperature of 1220°C for 50 minutes;

[0116] ⑺ Polishing, edging and chamfering the fired green body to obtain negative ion full-glazed porcelain glazed tiles.

[0117] The specific gravity of the glaze is 1.48 g / cm 3 , and the fineness is 1.3% on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proportion | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com