Tantalic oxide modified molybdenum disilicide based material and preparation method thereof

A technology of tantalum pentoxide and molybdenum disilicide, which is applied in the preparation of MoSi2-based composite materials and in the field of MoSi2-based composite materials, can solve the problems of not finding tantalum pentoxide-modified molybdenum disilicide-based composite materials, and achieve porosity Small, high-purity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

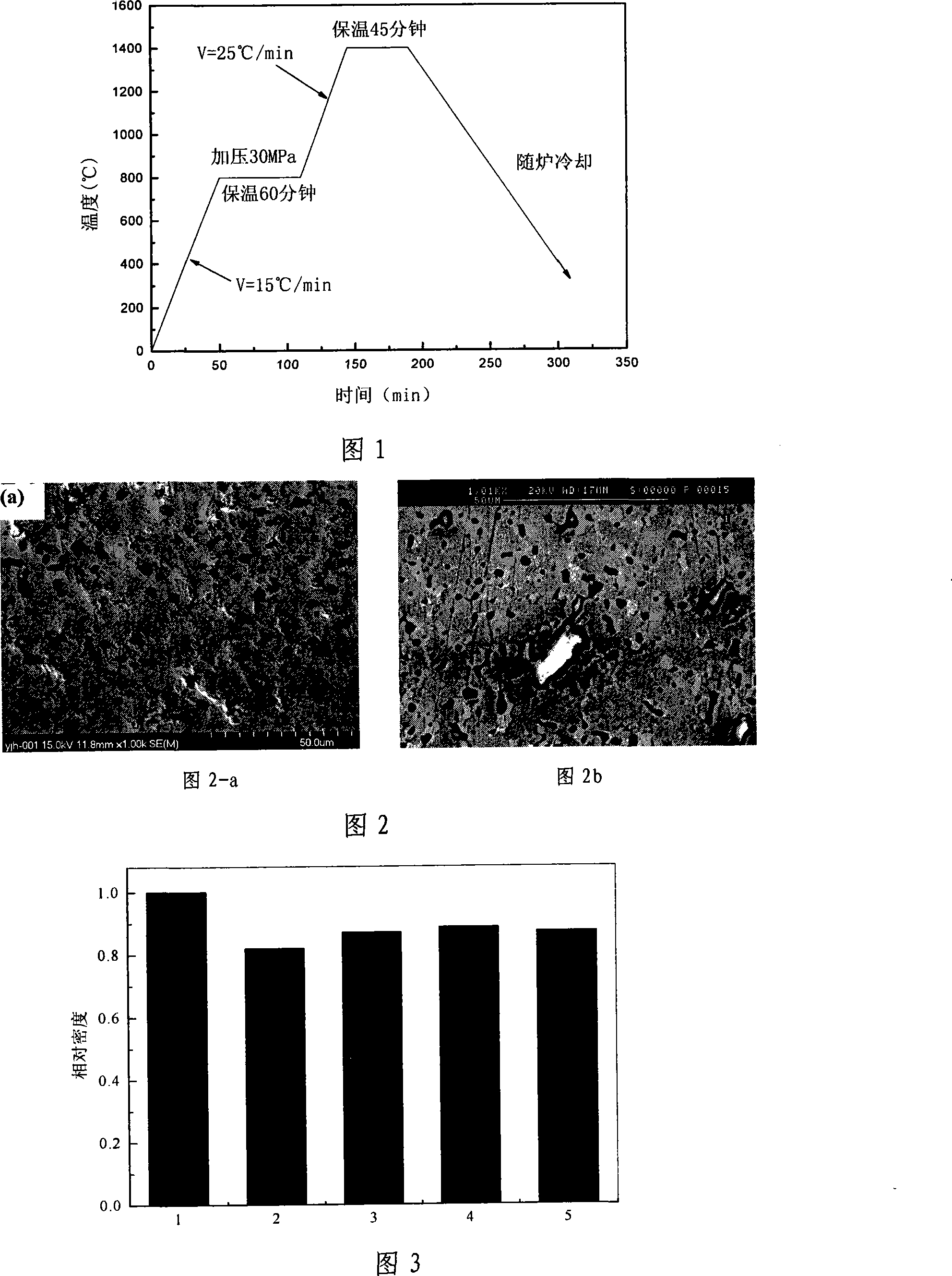

[0019] Embodiment: The hot-pressing sintering technology of the present invention is combined with ultrasonic wave and ball milling process, has obtained the Ta 2 o 5 doped MoSi 2 base composite material. 1%, 3%, 5%, 7% Ta by weight 2 o 5 and 93%-99% MoSi by weight 2 The powder was ultrasonically dispersed in a beaker filled with absolute ethanol for 30 minutes; the dispersed solution was put into a ball mill tank for ball milling for 4 hours, wherein the ball-to-material ratio was 20:1, and the speed was 450 rpm; the slurry after ball milling was The materials were freeze-dried, ground, and sieved, then put into graphite grinding tools, and sintered at 1400°C for 40 minutes to obtain Ta 2 o 5 / MoSi 2 Sintered body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com