Abrasion-resistant ceramic material and preparation method and application thereof

A technology of ceramic materials and raw materials, applied in the field of materials, can solve the problems of high cost and high dosage of zirconia, and achieve the effects of solving brittleness, simple raw materials, and easy control of preparation process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

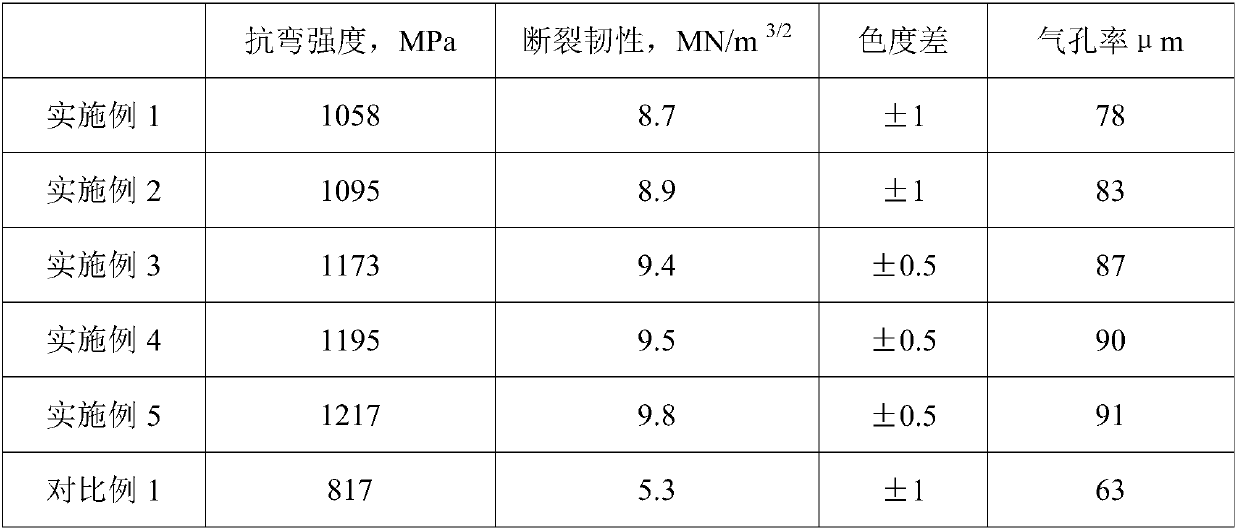

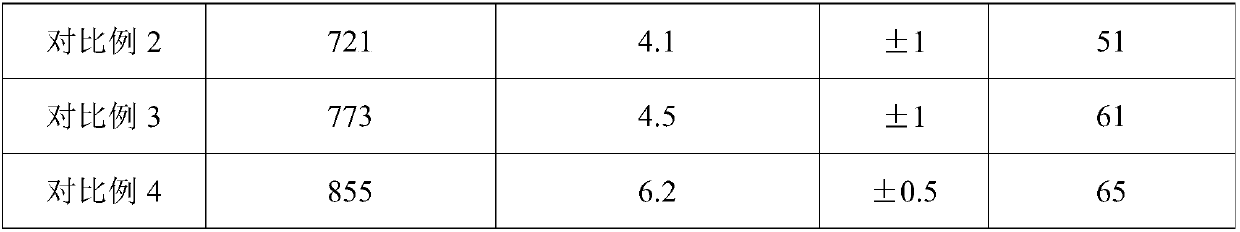

Examples

Embodiment 1

[0022] In an embodiment of the present invention, a wear-resistant ceramic material includes the following raw materials: 11 kg of zirconia, 1 kg of simethicone, 15 kg of levulinic acid, 22 kg of vermiculite, 3 kg of propylene carbonate, and 3 kg of ethyl cellulose.

[0023] Mix levulinic acid with 8.5 times the mass of deionized water to prepare a levulinic acid solution. Mix and grind zirconia, vermiculite, and ethyl cellulose, pass through a 150-mesh sieve, then add levulinic acid solution, heat up to 118°C, and seal and stir at this temperature for 2.2 hours at a stirring speed of 150r / min. Mixture A is obtained. Put simethicone and propylene carbonate into the mixture A, lower the temperature to 82°C, and seal and stir at this temperature for 1.5h, then raise the temperature to 140°C, and stir at this temperature for 1.1h, the stirring speed is 350r / min, then stop heating and ultrasonically treat for 30min, the ultrasonic power is 600W, centrifuge to get the precipitate...

Embodiment 2

[0025] In the embodiment of the present invention, a wear-resistant ceramic material includes the following raw materials: 19 kg of zirconia, 5 kg of simethicone, 25 kg of levulinic acid, 30 kg of vermiculite, 7 kg of propylene carbonate, and 7 kg of ethyl cellulose.

[0026] Mix levulinic acid with 8.5 times the mass of deionized water to prepare a levulinic acid solution. Mix and grind zirconia, vermiculite, and ethyl cellulose, pass through a 200-mesh sieve, then add levulinic acid solution, heat up to 120°C, and seal and stir at this temperature for 2.4 hours at a stirring speed of 150r / min. Mixture A is obtained. Put simethicone and propylene carbonate into the mixture A, lower the temperature to 85°C, and seal and stir at this temperature for 1.6h, then raise the temperature to 143°C, and stir at this temperature for 1.1h, the stirring speed is 350r / min, then stop heating and ultrasonically treat for 30min, the ultrasonic power is 600W, centrifuge to get the precipitat...

Embodiment 3

[0028] In an embodiment of the present invention, a wear-resistant ceramic material includes the following raw materials: 13 kg of zirconia, 2 kg of simethicone, 18 kg of levulinic acid, 24 kg of vermiculite, 4 kg of propylene carbonate, and 4 kg of ethyl cellulose.

[0029] Mix levulinic acid with 8.5 times the mass of deionized water to prepare a levulinic acid solution. Mix and grind zirconia, vermiculite, and ethyl cellulose, pass through a 200-mesh sieve, then add levulinic acid solution, heat up to 119°C, and seal and stir at this temperature for 2.3 hours at a stirring speed of 150r / min. Mixture A is obtained. Put simethicone and propylene carbonate into the mixture A, lower the temperature to 85°C, and seal and stir at this temperature for 1.6h, then raise the temperature to 143°C, and stir at this temperature for 1.1h, the stirring speed is 350r / min, then stop heating and ultrasonically treat for 30min, the ultrasonic power is 600W, centrifuge to get the precipitate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com