Preparation method of high-frequency induction assistant self-propagating NiAl intermetallic compound coating

An intermetallic compound and high-frequency induction technology, which is applied in the field of preparation of high-frequency induction-assisted self-propagating NiAl-based intermetallic compound coatings, achieves high heating efficiency, low cost, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

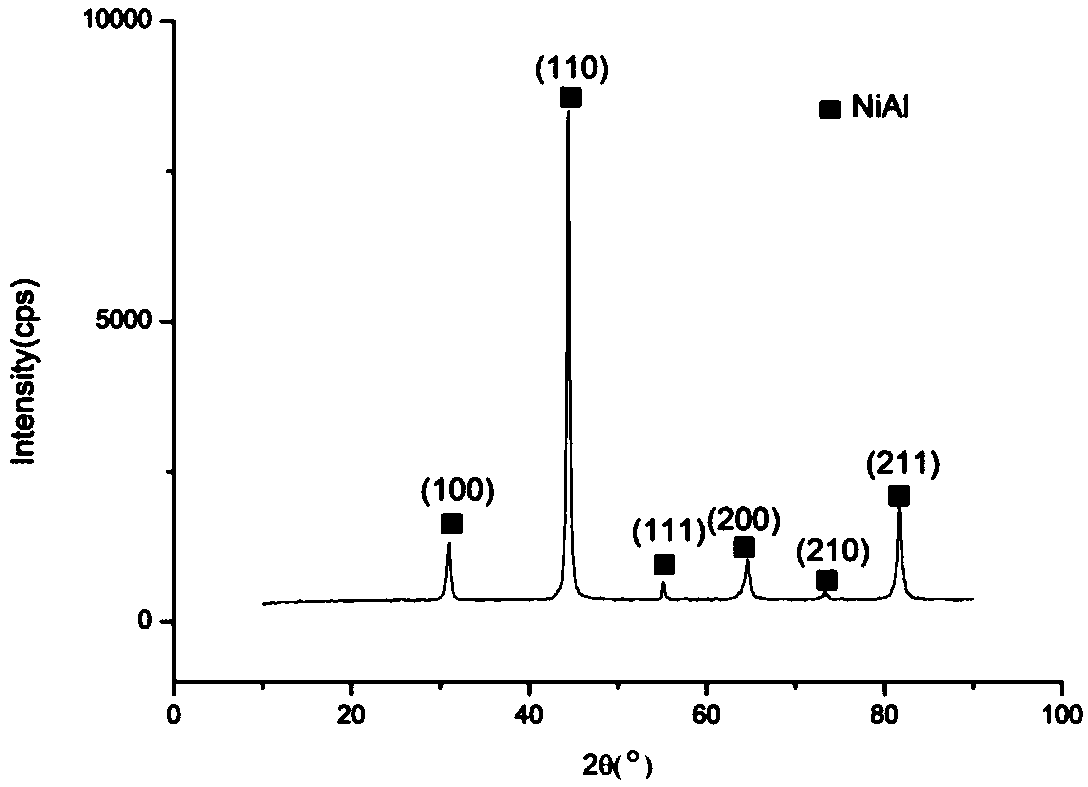

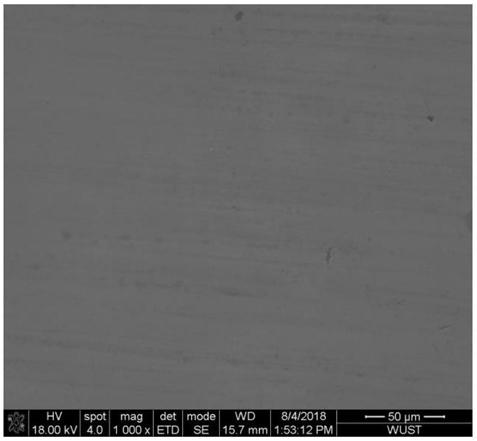

Embodiment 1

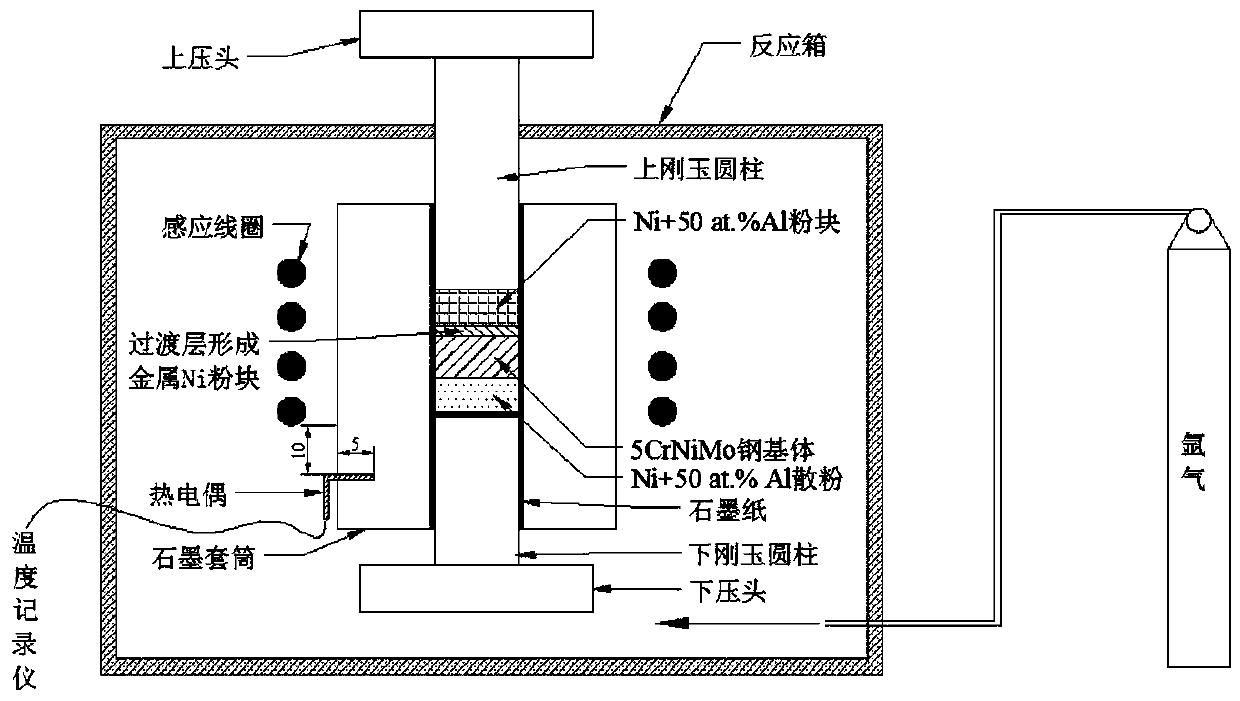

[0032] A preparation method for high-frequency induction-assisted self-propagating NiAl intermetallic compound coating, which comprises the following steps:

[0033] (1) Mix Ni powder and Al powder according to the ratio of Ni / Al atomic ratio of 1:1 and pour them into a beaker and stir evenly, then pour acetone, put the beaker in an ultrasonic cleaning machine and continue stirring, the water temperature is constant at 50°C , until the acetone volatilizes until it becomes difficult to stir, then put the beaker into a vacuum drying oven at a temperature of 85°C, and dry it in vacuum for 12 hours; then spread a certain amount of Ni powder on the bottom of the steel mold, and then ball mill the mixture Put the material into a mold, press it into a powder block with a density of 76%, and then place the pressed powder block in a vacuum drying box for standby.

[0034](2) Polish the surface of the 5CrNiMo steel plate with sandpaper to remove rust and other attachments, clean it with...

Embodiment 2

[0042] A preparation method for high-frequency induction-assisted self-propagating NiAl intermetallic compound coating, which comprises the following steps:

[0043] (1) Mix Ni powder and Al powder according to the ratio of Ni / Al atomic ratio of 1:1 and pour them into a beaker and stir evenly, then pour acetone, put the beaker in an ultrasonic cleaning machine and continue stirring, the water temperature is constant at 45°C , until the acetone volatilizes until it is difficult to stir, then put the beaker into a vacuum drying oven at a temperature of 95°C, and dry it under vacuum for 11 hours; then spread a certain amount of Co powder on the bottom of the steel mold, and then ball mill the mixture Put the material into a mold, press it into a powder block with a density of 80%, and then place the pressed powder block in a vacuum drying box for standby.

[0044] (2) Grind the surface of the H13 steel plate with sandpaper to remove rust and other attachments, clean it with absol...

Embodiment 3

[0050] A preparation method of high frequency induction assisted self-propagating NiAl coating, it comprises the steps:

[0051] (1) Mix Ni powder and Al powder according to the ratio of Ni / Al atomic ratio of 1:1, pour into a beaker and stir evenly, then pour acetone, put the beaker in an ultrasonic cleaning machine and continue stirring, the water temperature is constant at 55°C , until the acetone volatilizes until it is difficult to stir, then put the beaker into a vacuum drying oven at a temperature of 70°C, and dry it under vacuum for 15 hours; then spread a certain amount of Fe powder on the bottom of the steel mold, and then ball mill the mixture Put the material into a mold, press it into a powder block with a density of 70%, and then place the pressed powder block in a vacuum drying box for standby.

[0052] (2) Polish the surface of No. 45 steel plate with sandpaper to remove rust and other attachments, clean it with absolute ethanol, and put it in a sealed box for l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com