Thermal-state temping coking process

A technology of process and state, applied in the field of coking process, can solve the problems of increasing coke strength and reducing porosity, and achieve the effect of reducing porosity and improving tamping strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

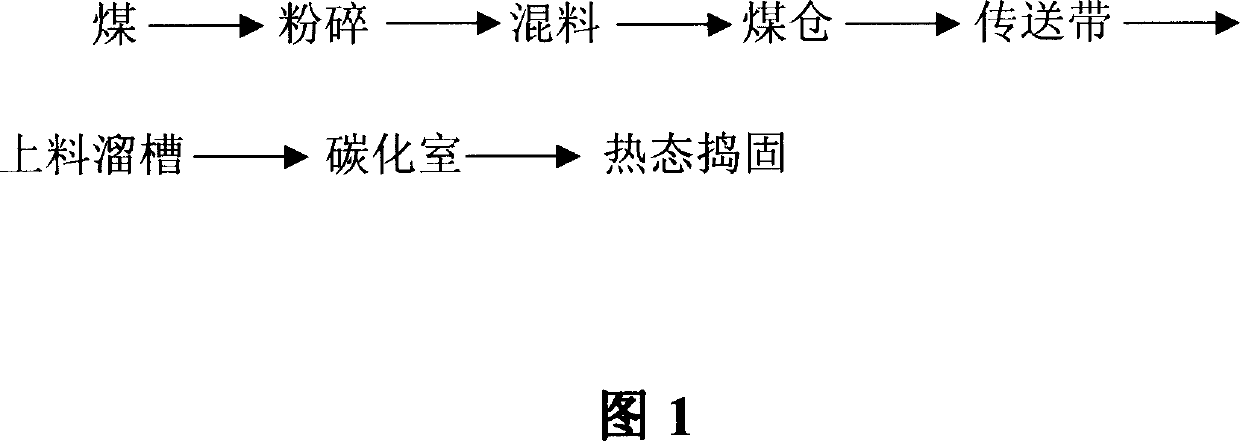

[0011] A thermal stamping coking process, characterized in that the coal is pulverized and mixed first, then enters the coal bunker, and then is sent to the feeding chute on the side of the carbonization chamber through a conveyor belt, and the coal in the carbonization chamber reaches 350-400°C At the same time, the coal in the reflow state is tamped by the tamping mechanism arranged on the top of the carbonization chamber, so that the coal is directly tamped into a dense coal cake in the carbonization chamber.

Embodiment 2

[0013] A thermal tamping coking process, characterized in that the coal is pulverized and mixed first, then enters the coal bunker, and then is sent to the feeding chute on the side of the carbonization chamber through a conveyor belt, and when the coal in the carbonization chamber reaches 380°C, The tamping mechanism installed on the top of the carbonization chamber tamps the coal in the reflow state, so that the coal is directly tamped into a dense briquette in the carbonization chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com