MgTiO3-Based microwave dielectric composite ceramic and preparation method thereof

A technology of microwave dielectric and composite ceramics, applied in ceramics, inorganic insulators, etc., can solve the problems of difficult sintering of materials and low dielectric loss, and achieve the effect of reducing porosity, low dielectric loss, and saving resources and energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

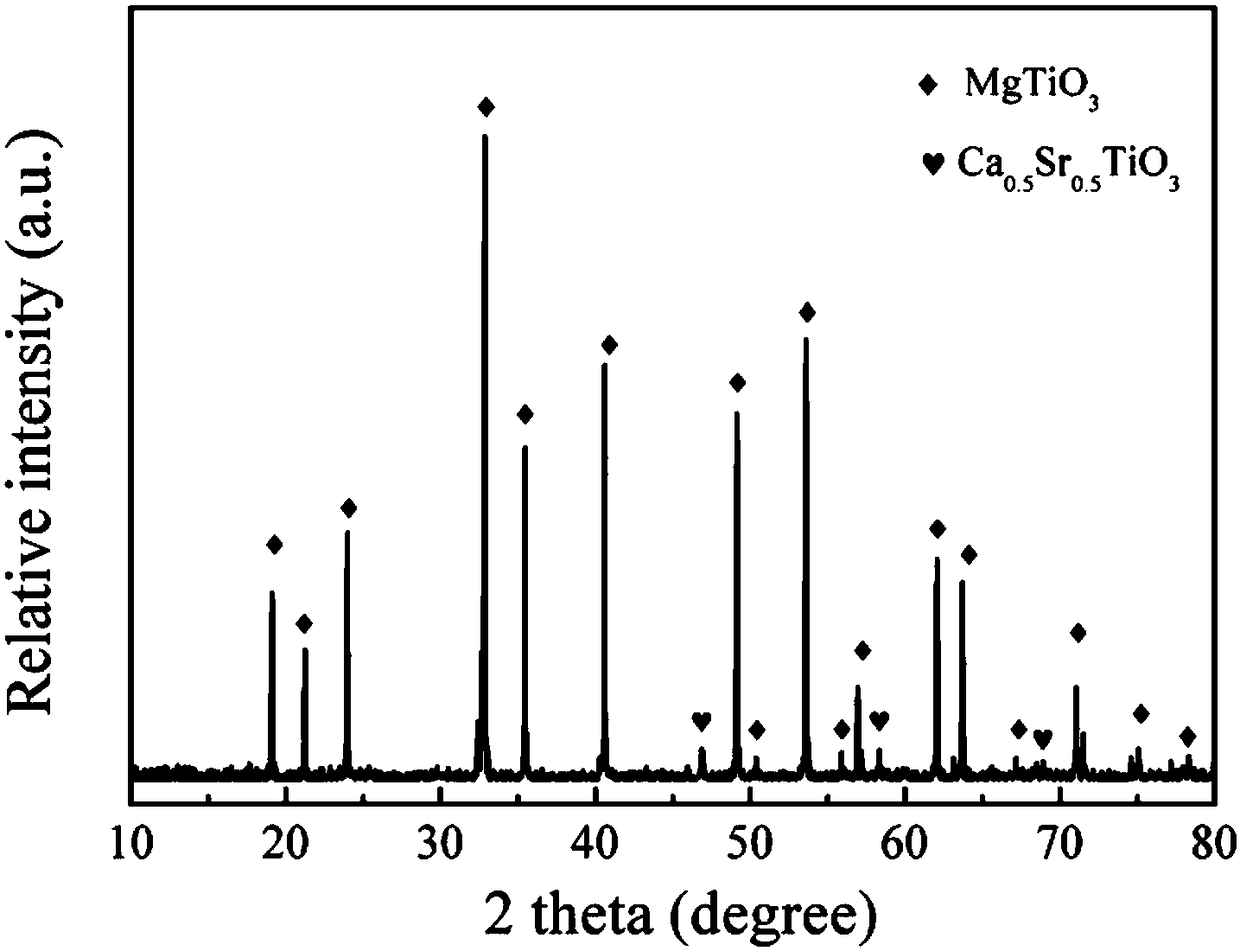

[0030] MgTiO proposed by the present invention 3 A corresponding preparation method of microwave-based dielectric composite ceramics comprises the following steps and contents:

[0031] (1) First, to analyze pure MgCl 2 ·6H 2 O, SrCl 2 ·6H 2 O, CaCl 2 、TiO 2 , AlCl 3 ·6H 2 O and LnCl 3 (Ln=Pr, Nd, La, Sm) as raw materials, analytically pure NaOH and KOH as precipitant and flux, respectively prepared MgTiO by molten salt method 3 , Ca 0.5 Sr 0.5 TiO 3 and LnAlO 3 (Ln=Pr, Nd, La, Sm) precursor powder. spare.

[0032] (2) Then, with the obtained MgTiO 3 Precursor powder as matrix, with Ca 0.5 Sr 0.5 TiO 3 or Ca 0.5 Sr 0.5 TiO 3 with LnAlO 3 The mixture of one of (Ln=Pr, Nd, La, Sm) is the additive, and each precursor powder is weighed according to the molar ratio of matrix and additive 1: (0.01~0.3), and mixed, ball milled, dried, ground, Granulating, sieving, dry pressing, and then sintering in a muffle furnace to obtain the MgTiO 3 Microwave-based dielec...

Embodiment 1

[0042] Embodiment 1: the high-performance MgTiO of the embodiment of the present invention 3 The preparation process of microwave-based dielectric composite ceramics is as follows:

[0043] (1) Weighing: First, weigh MgCl according to the molar ratio of 1:1:10:10 2 ·6H 2 O, TiO 2 , NaOH and KOH analytically pure reagent powder 20.33, 7.99, 40.01 and 56.11g respectively, standby; then, weigh SrCl according to the molar ratio of 0.5:0.5:1:8:8 2 ·6H 2 O, CaCl 2 、TiO 2 13.33, 5.55, 7.99, 32.01, and 44.89 g of analytically pure reagent powders of NaOH, KOH, and 44.89 g each, for later use.

[0044] (2) Primary ball milling: Put the two groups of reagents weighed into the ball milling tank of the stirring ball mill respectively, and add ZrO powder with 9 times the quality of the mixed powder. 2 Grinding balls and 5 times the mass of deionized water were ball milled and mixed for 24 hours.

[0045] (3) Primary drying: Dry the finely ground and mixed slurry in an atmospheric e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com