Zirconia ceramic, preparation method thereof, ceramic plunger and plunger pump

A zirconia ceramic, zirconia technology, applied in pump components, mechanical equipment, variable capacity pump components, etc., can solve the problem that the liquid medium pressure is difficult to meet the design requirements, the working efficiency of the plunger pump is reduced, and the internal structure is not good. Uniformity and other problems, to achieve the effect of fine grains, low porosity and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

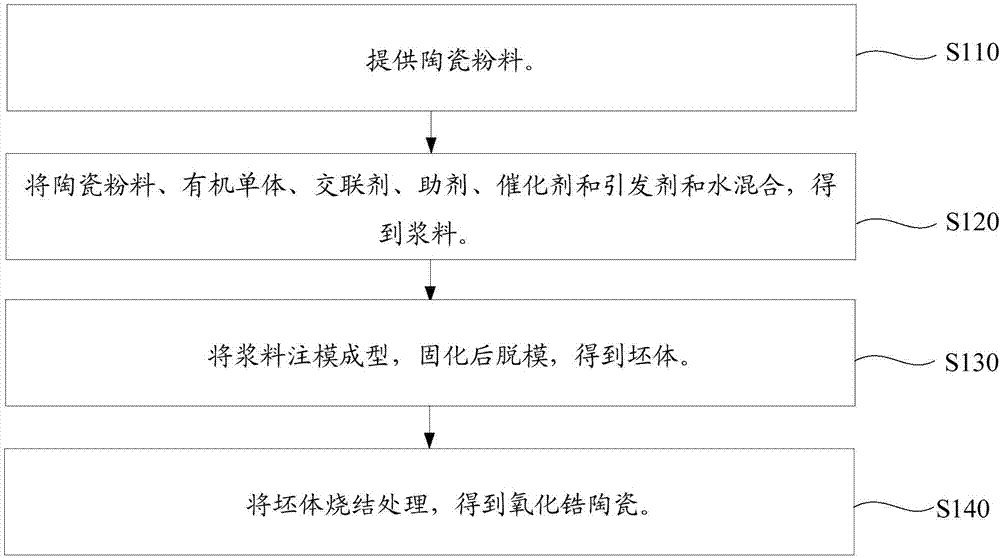

[0026] Such as figure 1 Shown, the preparation method of the zirconia ceramics of one embodiment, comprises the following steps:

[0027] Step S110: providing ceramic powder.

[0028] Among them, in terms of mass percentage, the ceramic powder is composed of the following components: 94% to 96% of zirconia, 3.5% to 5% of yttrium trioxide, 0.2% to 1% of aluminum oxide and 0.05% %~0.2% titanium dioxide.

[0029] Among them, the median particle size of zirconia (D 50 ) is 0.1 micron to 0.5 micron. If the particle size of zirconia is too large, it will easily lead to a large grain size, which is not conducive to improving the strength and toughness. If the particle size of the powder is too fine, the powder is likely to agglomerate and generate air bubbles, which is not conducive to the preparation of gel casting slurry, resulting in more defects in gel casting molding. Zirconia with this particle size is conducive to the formation of a relatively stable and uniform slurry, w...

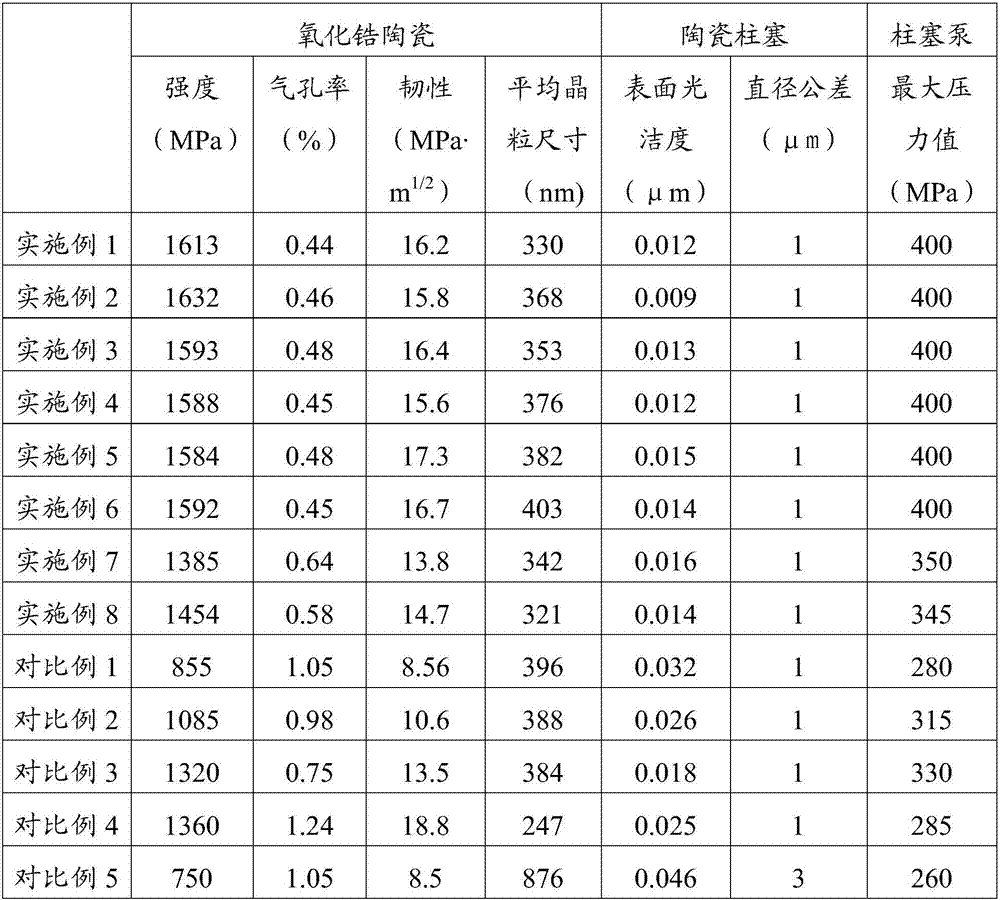

Embodiment 1

[0055] The preparation process of the ceramic plunger of the present embodiment is as follows:

[0056] (1) Provide ceramic powder. According to the mass percentage, the ceramic powder is composed of the following components: 96% zirconia, 3.5% yttrium oxide, 0.4% aluminum oxide and 0.1% titanium dioxide , wherein the median particle size of the zirconia is controlled to be 0.1 micron to 0.5 micron.

[0057] (2) dissolving the organic monomer and cross-linking agent in deionized water to obtain a premix; adding the premix to a ball mill tank, then adding ceramic powder, dispersant and plasticizer to ball mill for 22 hours to obtain a premix; Pour the primary mixture into a container, vacuum defoam for 60 minutes, stir and add catalyst and initiator to obtain slurry. Among them, the organic monomer is acrylamide, and the mass ratio of the organic monomer to the ceramic powder is 4:100; the cross-linking agent is N,N-dimethylacrylamide, and the mass ratio of the cross-linking a...

Embodiment 2

[0065] The preparation process of the ceramic plunger of the present embodiment is as follows:

[0066] (1) Ceramic powder is provided. According to the mass percentage, the ceramic powder is composed of the following components: 95% zirconia, 4.5% yttrium oxide, 0.4% aluminum oxide and 0.1% titanium dioxide , wherein the median particle size of the zirconia is controlled to be 0.1 micron to 0.5 micron.

[0067] (2) dissolving the organic monomer and cross-linking agent in deionized water to obtain a premix; adding the premix to a ball mill tank, then adding ceramic powder, a dispersant and a plasticizer to ball mill for 20 hours to obtain a premix; Pour the primary mixture into a container, vacuum defoam for 30 minutes, stir and add a catalyst and an initiator to obtain a slurry. Among them, the organic monomer is methylol acrylamide, and the mass ratio of the organic monomer to the ceramic powder is 4:100; the crosslinking agent is N,N-dimethylacrylamide, and the mass ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com