Chromium-alumina-carbon bricks and preparation method therefor

A chrome-aluminum-carbon brick and high-chromium technology, applied in the field of chrome-aluminum-carbon bricks and their preparation, can solve the problems of reducing the thermal shock performance of high chrome bricks, achieve thermal shock resistance improvement, reduce porosity, normal temperature and high temperature Strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

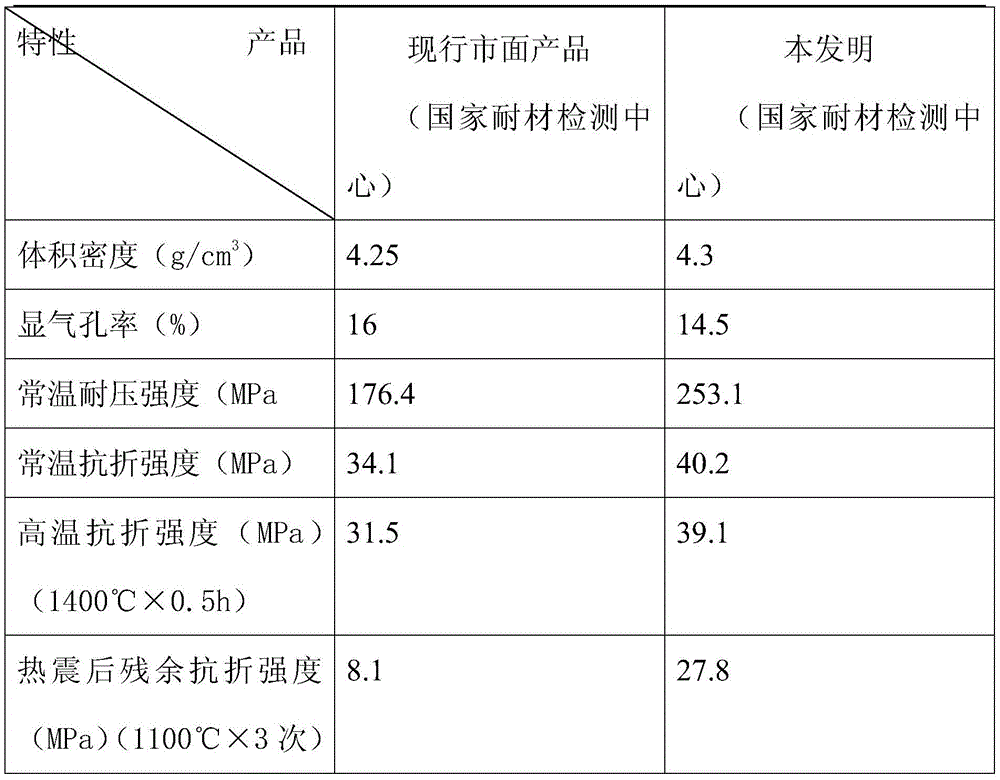

Examples

Embodiment 1

[0030] The components of a new chrome-aluminum carbon brick formula are as follows:

[0031] 5-1 47 parts of fused high chromium sand particles

[0032] 1~0 18 parts of fused high chromium sand particles

[0033] 18 parts of fused high chromium sand fine powder

[0034] 8 parts of alumina micropowder

[0035] 1 part aluminum powder

[0036] Zirconia micropowder: 3 parts

[0037] Graphite powder: 1 part

[0038] 4 parts chrome green

[0039] Add 2 parts of binder.

[0040] The preparation process of a new type of chrome-aluminum carbon brick is as follows:

[0041] 1. Ingredients: Weigh each raw material according to the formula requirements;

[0042] 2. Pre-mixing: add the weighed matrix fine powder into the vibrating ball mill for pre-mixing, and the mixing time is 30-60 minutes;

[0043] 3. Particle pre-packing: pre-mix aggregate particles with a particle size of 1mm or more, then add resin or pulp waste liquid binder, mix well, add metal aluminum powder, and contin...

Embodiment 2

[0049] The components of a new chrome-aluminum carbon brick formula are as follows:

[0050] 5-1 45 parts of fused high chromium sand particles

[0051] 1~0 20 parts of fused high chromium sand particles

[0052] 18 parts of fused high chromium sand fine powder

[0053] Aluminum oxide powder 6 parts

[0054] 1 part aluminum powder

[0055] Zirconia micropowder: 2 parts

[0056] Graphite powder: 2 parts

[0057] 6 parts chrome green

[0058] Add 2 parts of binder.

[0059] The preparation process of the above-mentioned a kind of backing aluminum-chromium-silica brick for pressurized coal-water slurry gasifier is the same as that in Example 1.

Embodiment 3

[0061] The components of a new chrome-aluminum carbon brick formula are:

[0062] 5-1 45 parts of fused high chromium sand particles

[0063] 1~0 20 parts of fused high chromium sand particles

[0064] 14 parts of fused high chromium sand fine powder

[0065] 10 parts of alumina micropowder

[0066] 0.5 parts of metal aluminum powder

[0067] Zirconia micropowder: 3 parts

[0068] Graphite powder: 1.5 parts

[0069] 6 parts chrome green

[0070] Add 2 parts of binder.

[0071] The preparation process of the aforesaid coal-water slurry pressurized gasifier with backing aluminum-chromium-silica brick is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com