Thermal sensitive ceramic material with low resistivity, high B value and negative temperature coefficient and preparation method thereof

A technology with negative temperature coefficient and low resistivity, which is applied in the field of negative temperature coefficient heat-sensitive ceramic materials, can solve problems such as unsatisfactory, high resistivity, and low resistance value requirements, and achieve reduced porosity, small resistivity, and improved pulse rate. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

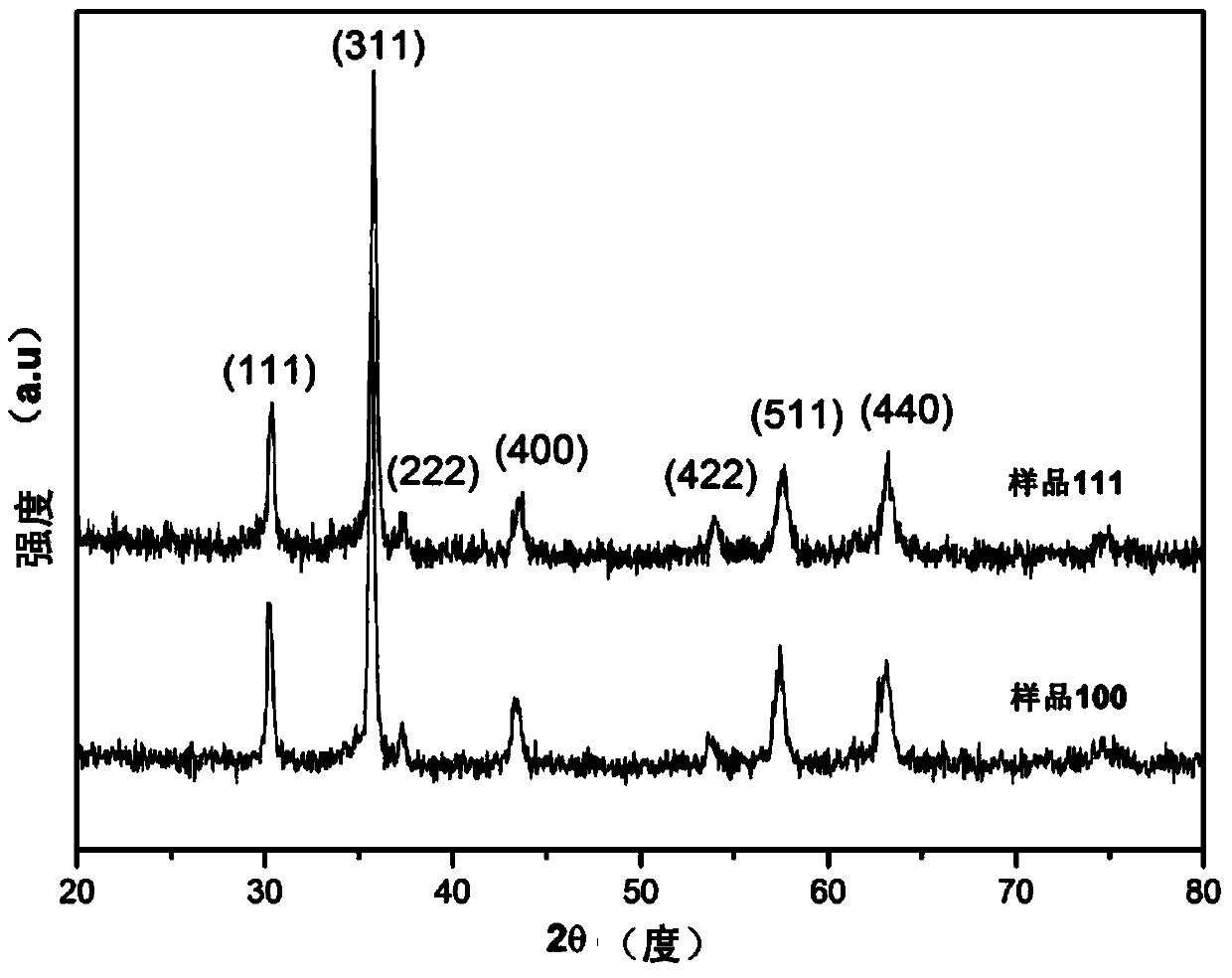

[0035] Using industrially pure MnO 2 , NiO, CuO, ZnO, Nb 2 o 5 with analytically pure Y 2 o 3 、Nd 2 o 3 The powder is used as the raw material, and the distribution ratio of each composition is as shown in Table 1. A total of 16 groups of samples are produced, and the negative temperature coefficient thermistor is prepared according to the following steps:

[0036] a. Weigh industrially pure main component MnO according to Table 1 2 , NiO, CuO and ZnO, put the powder in a polytetrafluoroethylene ball mill tank, add zirconium balls and deionized water, raw materials: ball: water = 1:1:1.5, use a planetary ball mill for ball milling, the speed is 250r / min, time 2h.

[0037] b. Dry the uniformly mixed slurry obtained in step a at 150°C, grind it evenly, place it in an alumina crucible, and pre-fire it at 950°C for 2.5 hours to obtain a powder with a spinel phase after pre-calcination .

[0038] c. The pre-fired powder is mixed with Y 2 o 3 , Nb 2 o 5 、Nd 2 o 3 , b...

Embodiment 2

[0057] The present embodiment adopts the same formula as the sample 111 in Example 1 (see Table 1), and prepares a negative temperature coefficient thermistor according to the following steps:

[0058] a. Weigh industrial pure main component MnO 2 , NiO, CuO and ZnO, put the powder in a polytetrafluoroethylene ball mill tank, add zirconium balls and deionized water, raw materials: ball: water = 1:1:1.5, use a planetary ball mill for ball milling, the speed is 250r / min, time 3h.

[0059] b. Dry the homogeneously mixed slurry obtained in step a at 180°C, grind it evenly, place it in an alumina crucible, and pre-fire at 930°C for 3 hours to obtain a powder with a spinel phase after pre-calcination.

[0060] c. The pre-fired powder is mixed with Y 2 o 3 , Nb 2 o 5 、Nd 2 o 3 , ball milled for 1 hour, dried and ground to obtain a uniformly mixed powder, added a polyvinyl alcohol solution with a concentration of 10wt%, and the added amount was 8wt% of the raw material, mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com