Continuous casting method for eliminating near-surface layer dendrite banded segregation of alloy spring steel wire rod

A technology of banded segregation and spring steel, applied in the field of metallurgy, can solve the problems of product change, without considering the solution of dendrite banded segregation defects, etc., achieve uniform surface metallographic structure, eliminate severe dendrite banded segregation, prevent Effect of interdendritic crack defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

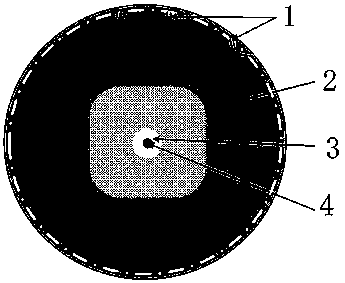

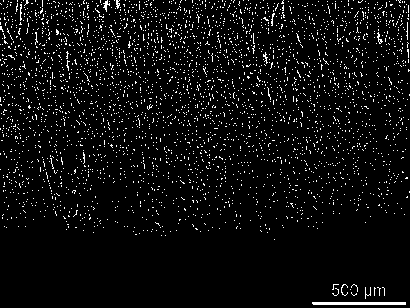

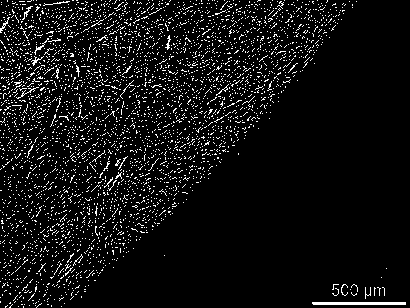

[0023] In this embodiment, the alloy spring steel wire rod steel grade is 55SiCrV, and the continuous casting method for eliminating the near-surface dendrite band segregation of the alloy spring steel wire rod includes the control of the superheat of molten steel in the continuous casting tundish, the control of the casting speed of the continuous casting slab, and the crystallizer. Electromagnetic stirring control, crystallizer water flow control and crystallizer vibration parameter control process, the specific process steps are as follows:

[0024] (1) Control of the superheat of molten steel in the continuous casting tundish: control the superheat of molten steel in the tundish at 15-18°C through the electromagnetic induction heating equipment of the tundish;

[0025] (2) Continuous casting slab casting speed control: the cross-sectional size of the crystallizer is 280mm×325mm, and the continuous casting slab casting speed is controlled at 0.65m / min;

[0026] (3) Electrom...

Embodiment 2

[0032] In this embodiment, the alloy spring steel wire rod steel grade is 55SiCr, and the continuous casting method for eliminating the dendrite band segregation near the surface of the alloy spring steel wire rod includes the control of the superheat of molten steel in the continuous casting tundish, the control of the casting speed of the continuous casting slab, and the crystallizer. Electromagnetic stirring control, crystallizer water flow control and crystallizer vibration parameter control process, the specific process steps are as follows:

[0033] (1) Control of the superheat of molten steel in the continuous casting tundish: control the superheat of molten steel in the tundish at 22-25°C through the electromagnetic induction heating equipment of the tundish;

[0034] (2) Continuous casting slab casting speed control: the cross-sectional size of the crystallizer is 280mm×325mm, and the continuous casting slab casting speed is controlled at 0.65m / min;

[0035] (3) Mold ...

Embodiment 3

[0041] In this embodiment, the alloy spring steel wire rod steel grade is 60Si2Mn, and the continuous casting method for eliminating the near-surface dendrite band segregation of the alloy spring steel wire rod includes the control of the superheat of molten steel in the continuous casting tundish, the control of the casting speed of the continuous casting slab, and the crystallizer. Electromagnetic stirring control, crystallizer water flow control and crystallizer vibration parameter control process, the specific process steps are as follows:

[0042] (1) Control of the superheat of molten steel in the continuous casting tundish: control the superheat of molten steel in the tundish at 19-22°C through the electromagnetic induction heating equipment of the tundish;

[0043] (2) Continuous casting slab casting speed control: the cross-sectional size of the crystallizer is 280mm×325mm, and the continuous casting slab casting speed is controlled at 0.65m / min;

[0044] (3) Mold ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com