Impact extrusion forming technology for aluminum alloy water heating parts and products thereof

A technology of cold extrusion and aluminum alloy, applied in the direction of metal extrusion, metal extrusion die, metal extrusion control equipment, etc., can solve the problem that the mechanical properties of the product cannot meet the requirements of use, and the cold extrusion technology cannot be formed well , high product sales prices and other issues, to achieve the effect of excellent mechanical properties, small specific gravity, high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

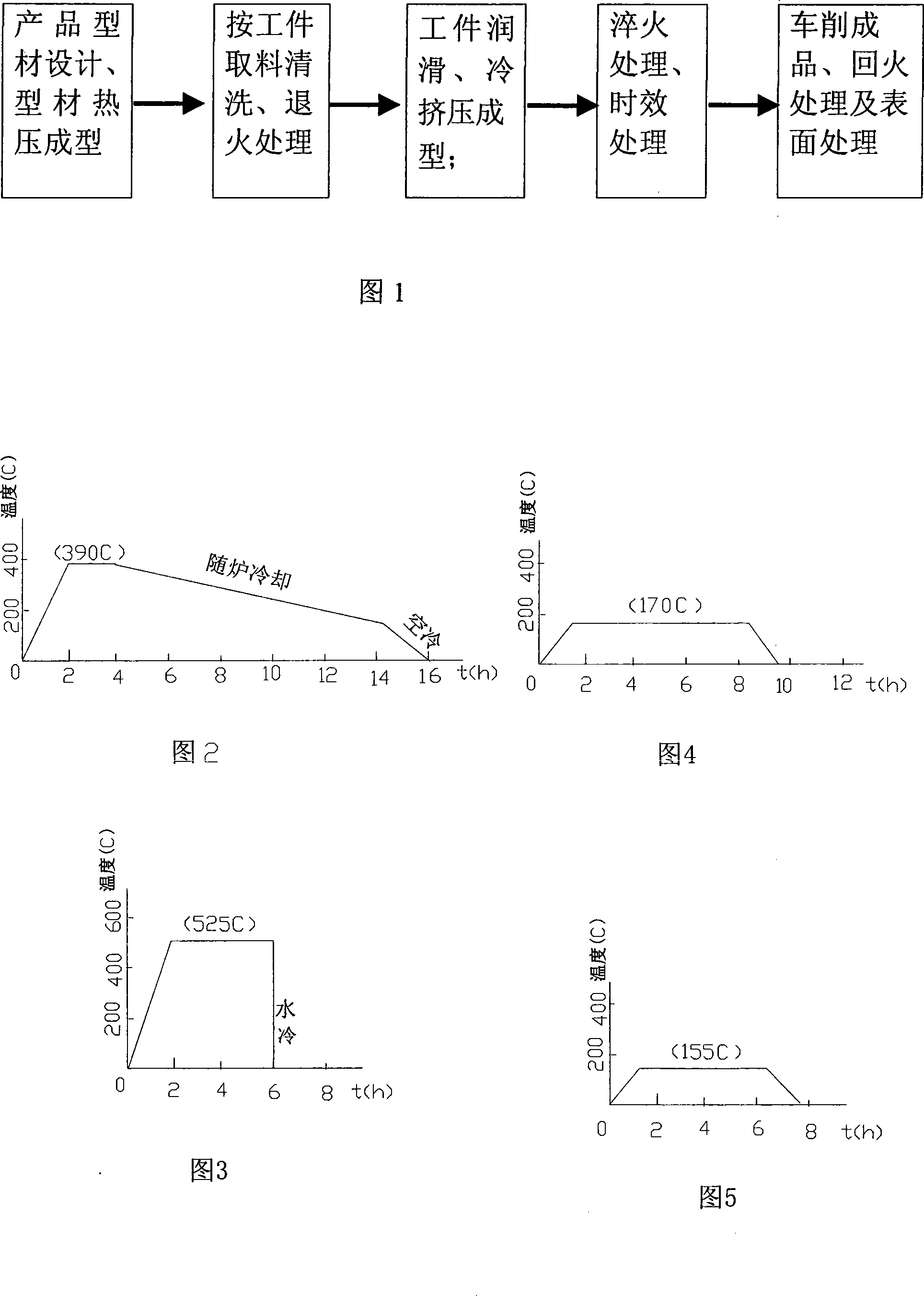

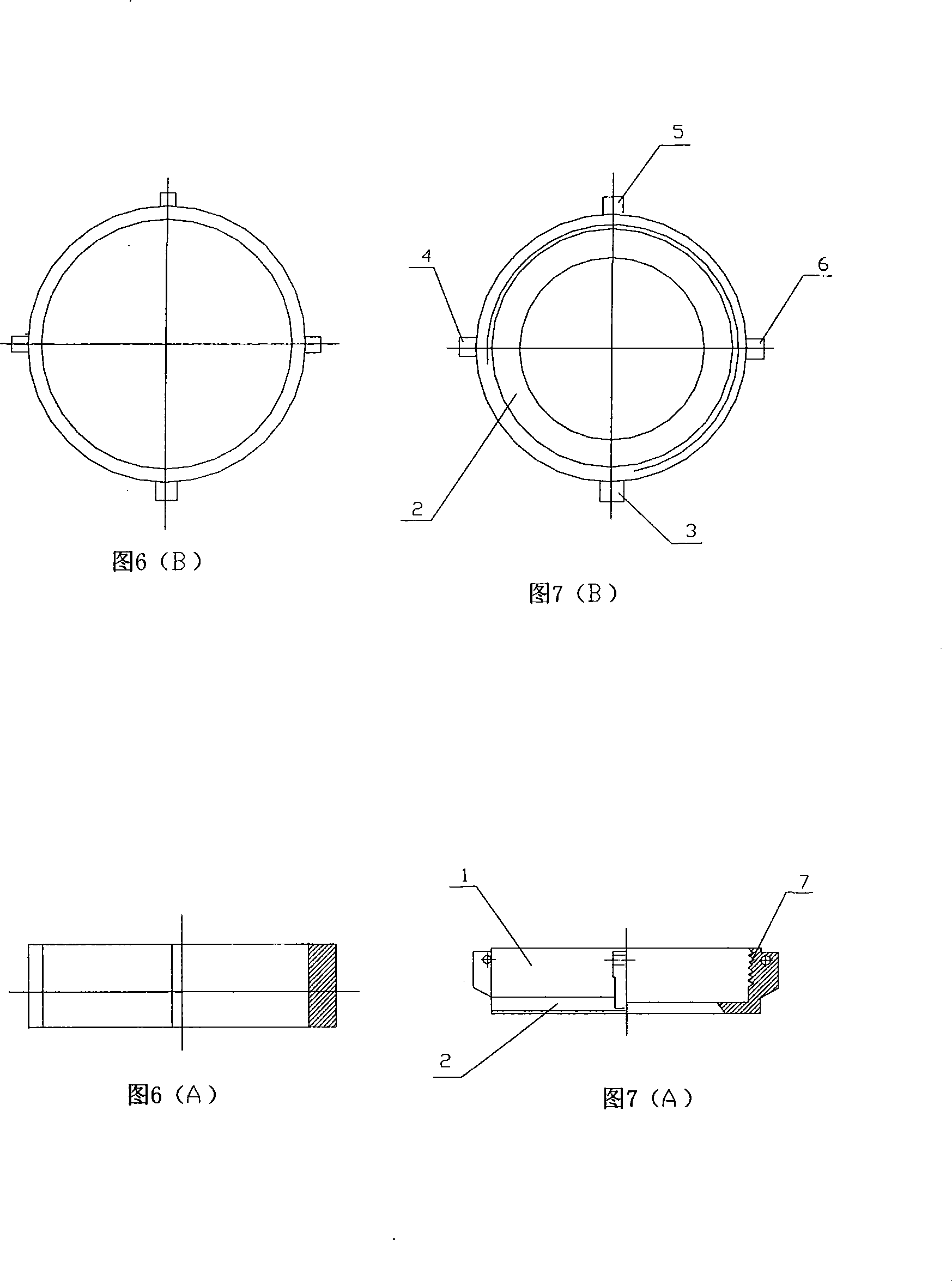

[0055] Use 6061 (LD30) forged aluminum alloy to make commonly used 15-25 type water meter cover (outer diameter 85mm): according to Figure 1 aluminum alloy plumbing parts cold extrusion molding technology steps, first, refer to the actual parts drawing (as attached Figure 7) Design the profile drawing (as shown in Figure 6); use 6061 (LD30) forged aluminum alloy, which is hot-extruded at 500-520℃ to become a 3.5-meter-long water meter cover sub-profile; and then according to the size of the workpiece (As shown in Figure 7) Take the material, make the weight of the profile 1.3 times the net weight of the product part, and clean it according to conventional techniques; Carry out annealing treatment according to Figure 2: heat to 390°C, keep the temperature for 2 hours, and cool with the furnace to 200 Below ℃, air-cooled from the furnace; zinc stearate is used as lubricant, while rolling and stirring; then cold extrusion molding: cold extrusion with 100T punch, one-time molding proc...

Embodiment 2

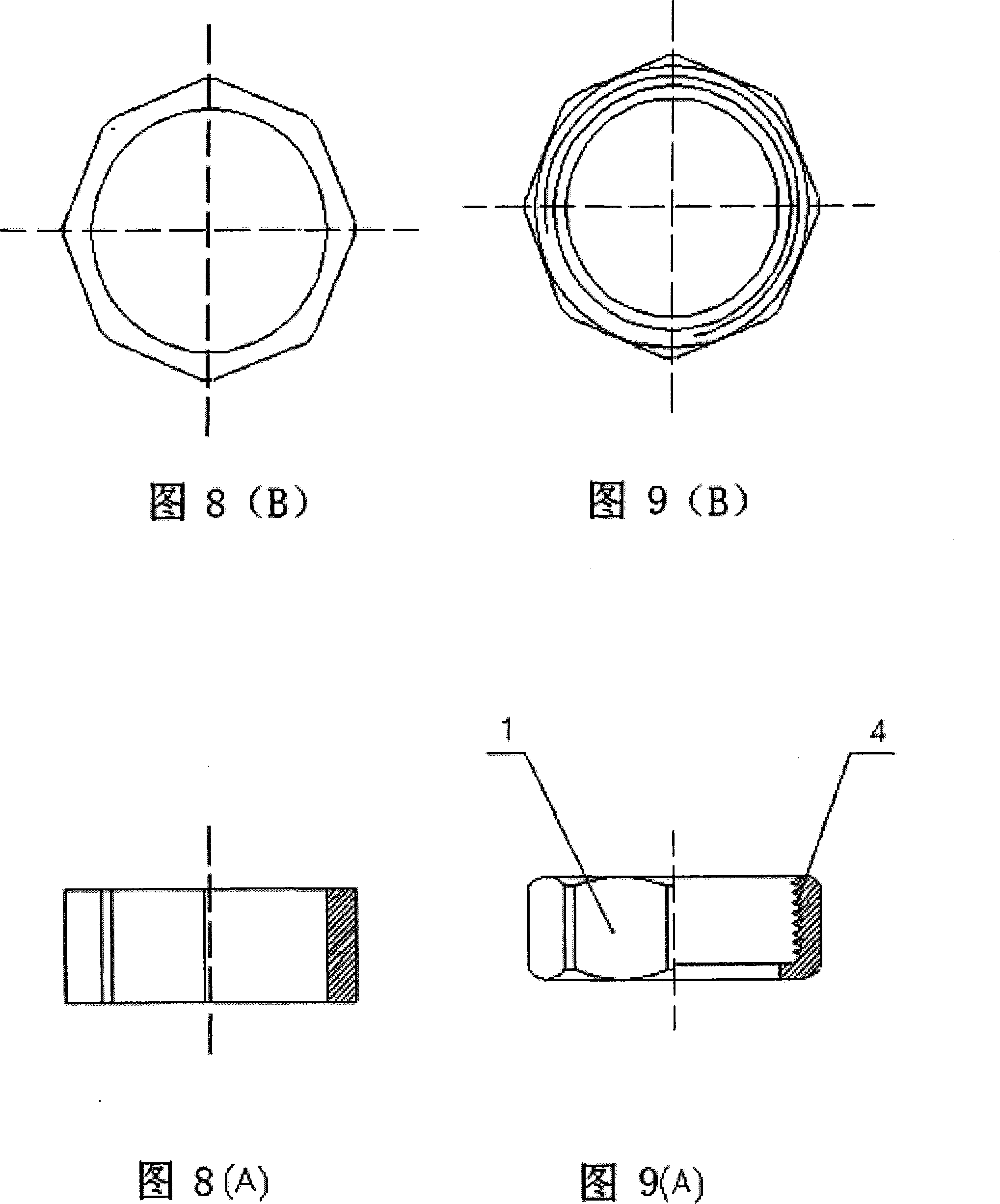

[0057] Use 6061-type forged aluminum alloy to make common 32-type plumbing joints: According to the technical steps of cold extrusion forming of aluminum alloy plumbing parts in Figure 1, first, refer to the actual part drawing (as shown in Figures 9, 11, and 13) to design the profile Figure (shown in Figures 8, 10, 12); using 6061 forged aluminum alloy, the plumbing pipe movable joint nut, inner wire and outer wire profile are produced by hot extrusion at 500-520℃, the profile length is 3.5 meters; The size of the workpiece is taken, so that the weight of the profile is 1.3 times the net weight of the product part, and cleaned according to conventional techniques; Annealing treatment according to Figure 2: heating to 390°C, holding for 2 hours, cooling with the furnace, to below 200°C, air cooling out of the furnace; Zinc stearate is used as lubricant, while rolling and stirring; then cold extrusion molding: cold extrusion using 160T punch, using one-time molding process, mold us...

Embodiment 3-7

[0059] According to Figure 1, the technical steps of cold extrusion forming of aluminum alloy plumbing parts:

[0060] 1. Take the raw material whose weight is 1.25-1.3 times of the molded product and extrude it at 500-520℃;

[0061] 2. Carry out cleaning and annealing treatment;

[0062] 3. After adding the lubricant and stirring, it is extruded and formed under the pressure above 160T in a normal temperature environment;

[0063] 4. Raise the temperature to 520-530°C and heat for 3-5 hours and then quench and quench, preferably at a heating temperature of 525°C, and preferably heat for 4 hours; or quench according to the prior art; heat up to 165-175°C and keep for 6-8 hours, Aging treatment;

[0064] 5. After turning into a finished product, heat it up to 150-160℃, keep it for 4-6 hours, perform tempering treatment, and then perform conventional treatments such as polishing the surface.

[0065] The specific technical parameters involved are shown in the following table:

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com