Weather-proof flame-retardant masterbatch for PP plate and preparation method of weather-resistant flame-retardant masterbatch

A color masterbatch and weather-resistant technology, which is applied in the field of polymers, can solve the problems of weakening the flame-retardant effect, single-functional masterbatch, and failure to achieve weather resistance and flame retardancy, and achieve bright colors, good flame-retardant effects, high gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

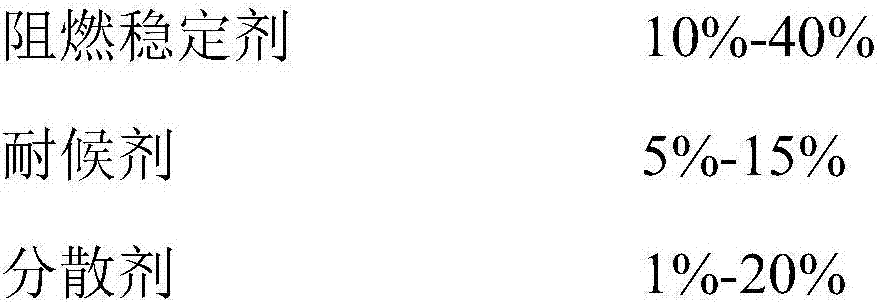

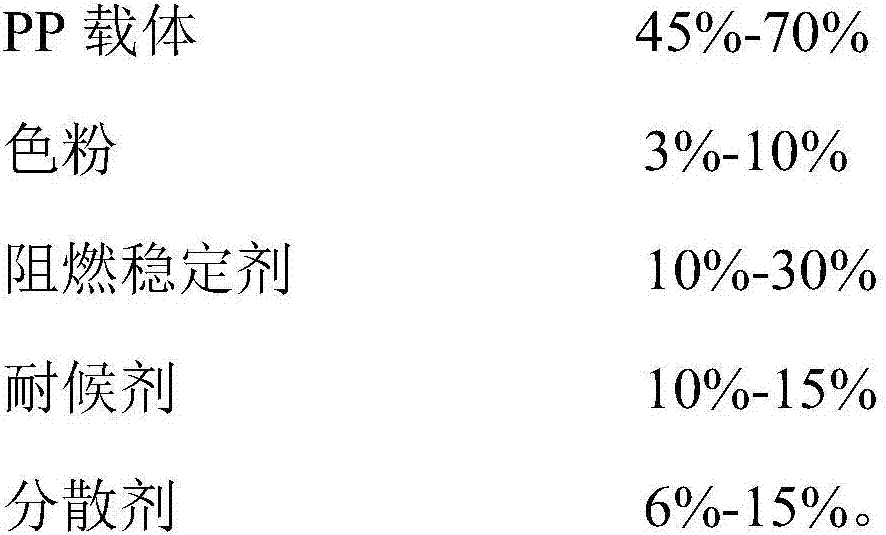

[0026] A batch of weather-resistant and flame-retardant masterbatches for PP boards are composed of the components in Table 1 by weight percentage.

[0027]

[0028] Table 1

[0029] A better preparation method of weather-resistant flame-retardant masterbatch for PP board, including the following steps

[0030] (1) In the high-speed mixer, first add the PP carrier, and then add the remaining ingredients in the above ratio in sequence, and stir for 1-20 minutes at a speed of 1000RPM-4000RPM;

[0031] (2) After standing for 2-5 minutes, pour out all the mixture in the mixer from the outlet, and then add it to the mixer again. Repeat step (1);

[0032] (3) Pour the mixture in the mixer into the feeding barrel of the co-rotating twin-screw extruder (length-to-diameter ratio 38:1-48:1), turn on the extruder, the feed speed is 200-550RPM, the main screw speed is 200 -550RPM, the temperature of each zone is set to 155-210℃, and it can be packaged after water cooling, air cooling, cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com