Crosslinked ethylene-tetrafluoroethylene copolymer insulating material

A technology of tetrafluoroethylene and cross-linked ethylene, applied in the direction of insulators, insulated conductors, insulated cables, etc., can solve the problems of large smoke generation, harsh processing temperature requirements, poor thermal stability, etc., and achieve low smoke generation and tensile strength High retention rate of strength and elongation at break, good anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0027] Embodiments 1-3: A cross-linked ethylene-tetrafluoroethylene copolymer insulating material, consisting of the following components by mass:

[0028] 100 parts of ethylene-tetrafluoroethylene copolymer,

[0029] Prepolymer crosslinking agent 0.3~8 parts,

[0030] N, N'-bis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hydrazine 0.1~1 part,

[0031] 0.5~3 parts of 1,3,5-tris(3,5-di-tert-butyl-4-hydroxybenzyl)isocyanuric acid,

[0032] Antimony trioxide 1~5 parts,

[0033] 1~3 parts of antimony pentoxide,

[0034] N,N'-ethylene bis stearamide 0.1~2 parts

[0035] 0.1~0.5 parts of pentaerythritol stearate,

[0036] 0.1~3 parts of white oil;

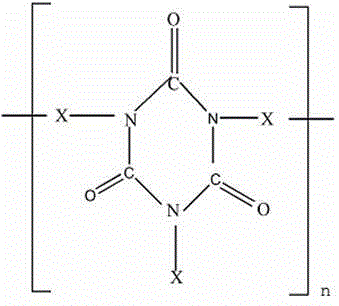

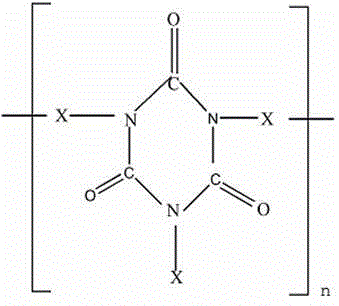

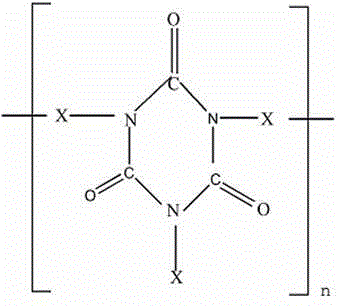

[0037] The chemical structural formula of the prepolymer crosslinking agent is as follows:

[0038]

[0039] Where X is vinyl, allyl, methallyl, propargyl or a combination of the above, n= 2~15;

[0040] The weight average molecular weight of the prepolymer crosslinking agent is 600~3000, and the 1,3,5-tris(3,5-di-tert-buty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com