Synergetic intumescent flame-retardant polypropylene composite material and preparation method thereof

A flame-retardant polypropylene and composite material technology, applied in the field of flame-retardant polypropylene materials, can solve the problems of high flame-retardant efficiency, high water solubility, and small addition amount, and achieve high flame-retardant efficiency, low smoke density, and high emission small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

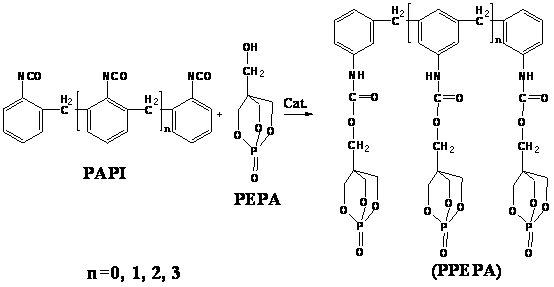

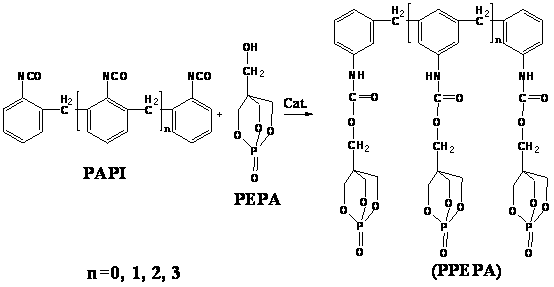

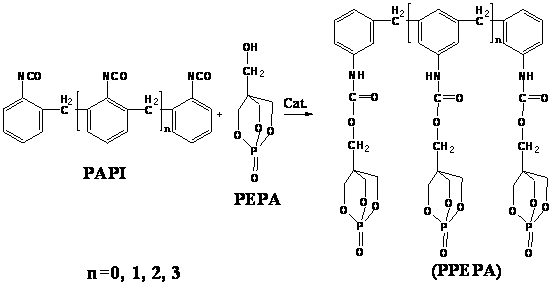

[0025] After weighing 3.97kg of polypropylene pellets and 0.015kg of zinc stearate, put them into a high-speed mixer for pre-mixing for 5 minutes, so that zinc stearate adheres to the surface of polypropylene pellets, and then add Ammonium polyphosphate (APP) 0.6kg, phosphorus-nitrogen type carbon forming agent (PPEPA) 0.4kg and 1010 antioxidant 0.015kg were mixed for 5 minutes and mixed evenly, then extruded in a twin-screw extruder, cooled, Pelletizing to obtain synergistic expansion flame-retardant polypropylene composite material. Among them, the temperature setting of each zone of the twin-screw extruder is as follows: 160°C, 170°C, 175°C, 185°C, 190°C, 200°C, 200°C, 190°C, 185°C, 180°C. The oxygen index of the polypropylene composite material is 28.0%, and the UL-94 test reaches the V-0 level.

[0026] In this example, the ammonium polyphosphate (APP) described above is crystalline type II ammonium polyphosphate with a high degree of polymerization, and the structural f...

Embodiment 2

[0031] After accurately weighing 3.93kg of polypropylene pellets and 0.010kg of calcium stearate, put them into a high-speed mixer for pre-mixing for 5 minutes, so that calcium stearate adheres to the surface of polypropylene pellets, and then mix them in a high-speed mixer Add 0.55kg of melamine polyphosphate (MPP), 0.45kg of phosphorus-nitrogen carbon forming agent (PPEPA) and 0.010kg of timely 68 antioxidant, and 0.05kg of 4A molecular sieve in the high-speed dispersant, and then in the twin-screw machine Extrude in an extruder, cool and granulate to obtain a synergistic expansion flame-retardant polypropylene composite material. Among them, the temperature setting of each zone of the twin-screw extruder is as follows: 165°C, 170°C, 175°C, 185°C, 190°C, 200°C, 200°C, 190°C, 185°C, 180°C. The oxygen index of the polypropylene composite material is 33.0%, and the UL-94 test reaches the V-0 level.

[0032] In this embodiment, the structural formula of melamine polyphosphate (...

Embodiment 3

[0037] Accurately weigh 3.85kg of polypropylene pellets and 0.11kg of N,N-ethylene bisstearic acid amide (EBS), place them in a high-speed disperser and stir for 9 minutes, then add 0.5kg of melamine polyphosphate (MPP), phosphorus - Nitrogen-type carbon forming agent (PPEPA) 0.5kg, 1010 antioxidant 0.010kg and cerium oxide 0.03kg are pre-mixed in a high-speed dispersant for 15 minutes, then extruded in a twin-screw extruder, cooled, and granulated. The halogen-free flame-retardant polypropylene composite material can be obtained. Among them, the temperature setting of each zone of the twin-screw extruder is as follows: 150°C, 170°C, 175°C, 185°C, 190°C, 200°C, 200°C, 190°C, 185°C, 180°C. The oxygen index of the polypropylene composite material is 34.5%, and the UL-94 test reaches the V-0 level.

[0038] In this embodiment, in this embodiment, the structural formula of melamine polyphosphate (MPP) is: , n≥1000, the content of ammonium polyphosphate (APP) or melamine polypho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com