HDPE pipe material and preparing method thereof

A kind of pipe, formula technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of hindered phenol quaternary ammonium salt modified montmorillonite: Add 400mL deionized water and 5 parts of montmorillonite to a 500mL three-necked flask equipped with magnetic stirring, condenser and thermometer, and heat in a water bath at 60°C for 4h. Add 5 parts of hindered phenol quaternary ammonium salt dissolved in solvent dropwise, continue to react for 8 hours, filter with suction, wash the filter cake with deionized water, wash with 50% ethanol solution until there is no chloride ion, dry at 100°C, and grind through a 200-mesh sieve spare.

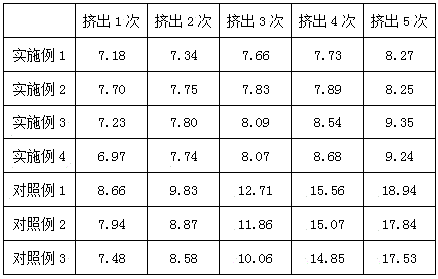

[0037] (2) Application of hindered phenol quaternary ammonium salt modified montmorillonite antioxidant and phosphite antioxidant compound application: raw materials in parts by weight: add 3 parts of the above synthesized hindered phenol quaternary to 96.7 parts of HDPE Ammonium salt modified montmorillonite antioxidant, 1680.3 parts of antioxidant, after extruding 1, 2, 3, 4, 5 times on a twin-screw ex...

Embodiment 2

[0040] The preparation method of this example is the same as that of Example 1, except that in the formula of step (2) of this example, the mass fraction of HDPE is 95.7 parts, and the hindered phenol quaternary ammonium salt modified montmorillonite is 4 parts, Pentaerythritol bisphosphite is 0.3 parts.

Embodiment 3

[0042] The preparation method of this example is the same as that of Example 1, except that, in the formula of step (2) of this example, the mass fraction of HDPE is 97 parts, and the hindered phenol quaternary ammonium salt modified montmorillonite is 3 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com