Double-bond saturation isomerism etherifying process for improving oxidation resistance and pouring point of plant oil

A technology of vegetable oil and isomerized ether, applied in the field of lubricating oil technology and tribochemistry, can solve the problem of no further drop in pour point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

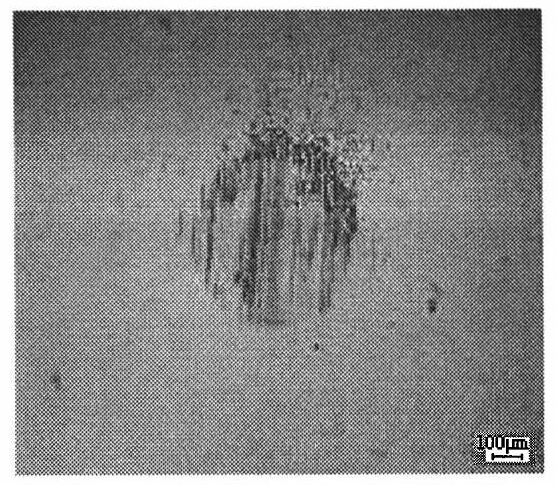

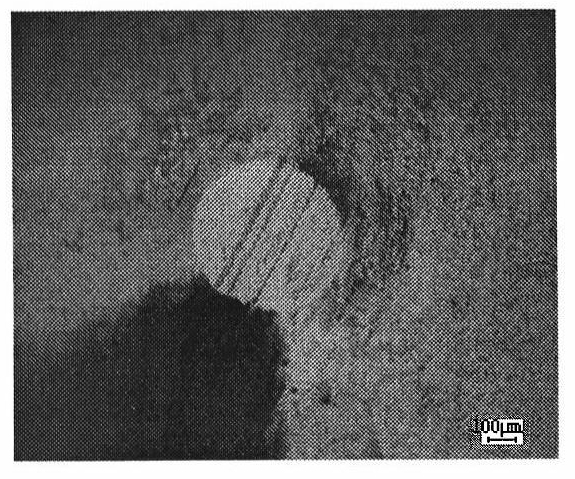

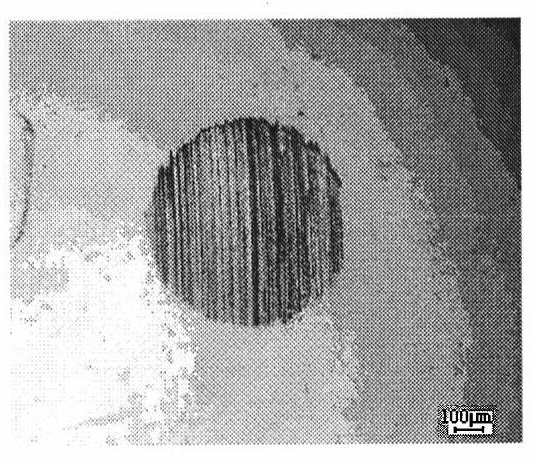

Image

Examples

Embodiment 1

[0037] One of the improvements in the present invention is an epoxy etherification reaction.

[0038] Because the vast majority of natural vegetable oils contain unsaturated double-bond fatty acid glyceride structures with the same chemical structure (the chemical structure of its main component is straight-chain unsaturated carboxylic acid glycerides with 18-22 carbon atoms, such as rapeseed oil, soybean oil , peanut oil, cottonseed oil, sesame oil, corn oil, etc.). Rapeseed oil is widely available in my country and is a typical unsaturated fatty acid glyceride. In this example, industrial rapeseed oil is used as a representative raw material to carry out epoxidation etherification reaction (other vegetable oils can carry out the same etherification reaction).

[0039] 1. Synthesis of Modified Rapeseed Oil

[0040] Add a certain amount of rapeseed oil into a three-neck flask, insert a separatory funnel with a certain amount of glacial acetic acid, hydrogen peroxide and conc...

Embodiment 2

[0064] Epoxy Etherification Esterification

[0065] Castor oil has the lowest pour point of all vegetable oils. In order to obtain a synthetic oil with a lower pour point, castor oil is used as a representative raw material for epoxy etherification and esterification.

[0066] 1. Synthesis of Modified Castor Bean

[0067] Add a certain amount of castor oil into a three-neck flask, insert a separatory funnel with a certain amount of glacial acetic acid, hydrogen peroxide and concentrated sulfuric acid at one end of the bottle mouth, preheat to 40°C, stir, add dropwise, and keep the temperature at 40-60°C ℃, the dropwise addition is completed in one hour, and the temperature is kept at 60-65 ℃, and the reaction is continued for 3 hours. Pour out the reaction material, put it in a separatory funnel, wash it with a weight concentration of 0.5-1% dilute alkali to pH=5, release the water phase after layering, pour the oil phase back into the reactor, add a little Excessive iso-oc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com