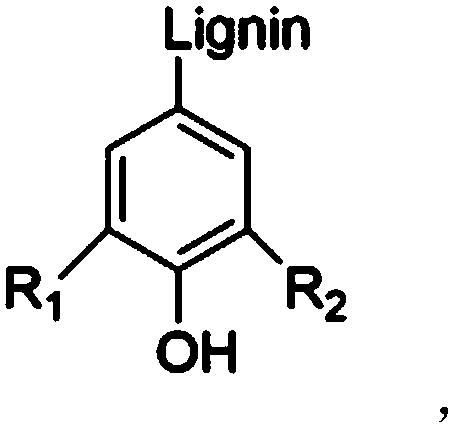

Multifunctional lignin arylamine macromolecular antioxidant and preparation method and application thereof

A macromolecular antioxidant and multi-functional technology, applied in the production of bulk chemicals, etc., can solve the problems that are not related to the antioxidant performance of lignin aromatic amines, aromatic amines and lignin, etc., and achieve a significant antioxidant effect , Improve the antioxidant capacity, improve the effect of dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

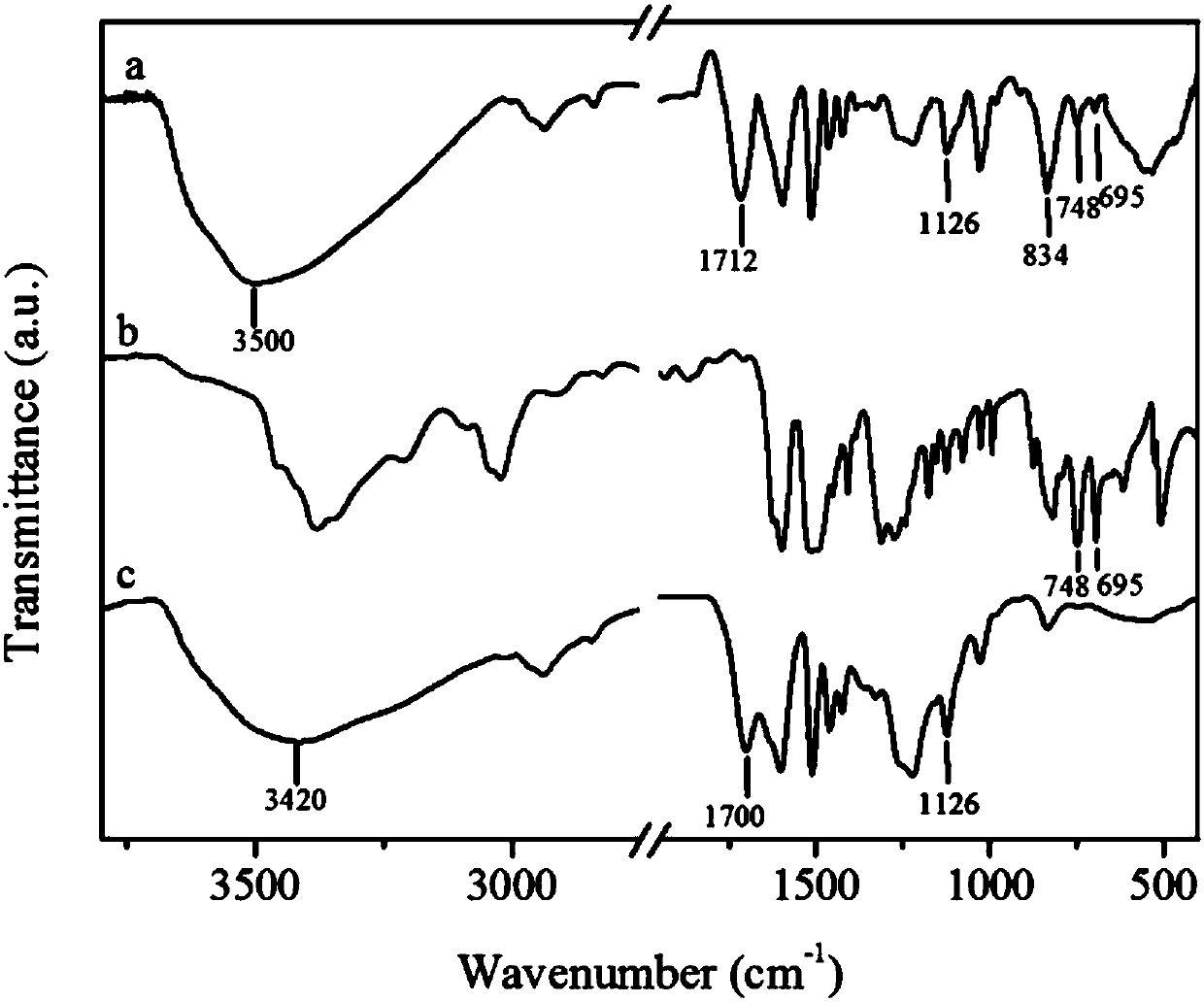

Method used

Image

Examples

Embodiment 1

[0030] (1) Prepare a mixed solution of alkali lignin and N-phenyl-p-phenylenediamine: add alkali lignin, N-phenyl-p-phenylenediamine, and water into a three-necked flask at a mass ratio of 100:44.2:800, and then add The pH value of the solution was adjusted by sodium hydroxide to 12, heated and stirred at 70° C. for 1 hour, so that the alkali lignin and N-phenyl-p-phenylenediamine were fully dissolved and mixed uniformly.

[0031](2) Reaction: Under the protection of nitrogen, slowly drop formaldehyde (addition amount 6g formaldehyde / 100g lignin) into the mixed solution obtained in step (1), and heat and stir at 70°C for 3 hours.

[0032] (3) Product purification: adjust the pH value of the solution obtained in step (2) to 2.5 with 5% sulfuric acid solution, heat up to 90° C. and keep warm, filter after caking, and wash 5 times with hot water to remove unreacted small molecules And inorganic salts, followed by washing 3 times with absolute ethanol to remove unreacted aromatic ...

Embodiment 2

[0038] The other steps of this embodiment are the same as in Example 1, except that the application of the synthetic lignin arylamine macromolecular antioxidant in natural rubber adopts the method of blending with natural rubber latex: 1 part of synthetic lignin Aromatic amine macromolecular antioxidant is added in the sodium hydroxide solution of a certain amount of 0.1mol / L and is mixed with the antioxidant solution of 10% solid content, and above-mentioned antioxidant solution is joined to the natural rubber of 167 parts of solid content 60% latex (100 parts of raw rubber), mixed and stirred evenly, then demulsified with 1mol / L dilute hydrochloric acid and washed with deionized water, and finally dried to obtain natural rubber raw rubber containing lignin aromatic amine macromolecular antioxidant. The steps and formula of preparing mixed rubber and vulcanized rubber are all the same as in Example 1, and the corresponding vulcanization time is 413s.

Embodiment 3

[0040] The other steps of this embodiment are the same as in Example 1, except that the mass ratio of alkali lignin, N-phenyl-p-phenylenediamine, and water in step (1) is 100:66.3:900, and formaldehyde in step (2) The dosage is 9g / 100g lignin, and the corresponding vulcanization time is 372s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com