Dedicated emulsion-type composite anti-oxidant for MBS (methyl methacrylate-butadiene-styrene) and preparation method of the dedicated emulsion-type composite anti-oxidant

A composite antioxidant, emulsion type technology, applied in the field of preparation of MBS resin, can solve the problems such as difficult to uniformly disperse oxidant solid particles, poor antioxidation effect, and no reports yet, achieve environmental protection, antioxidation and other problems. Good effect, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

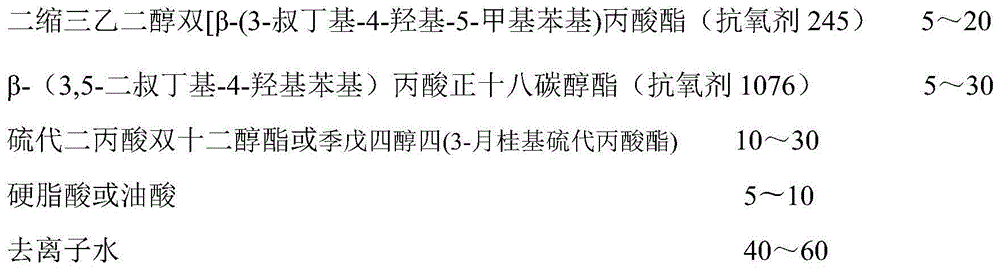

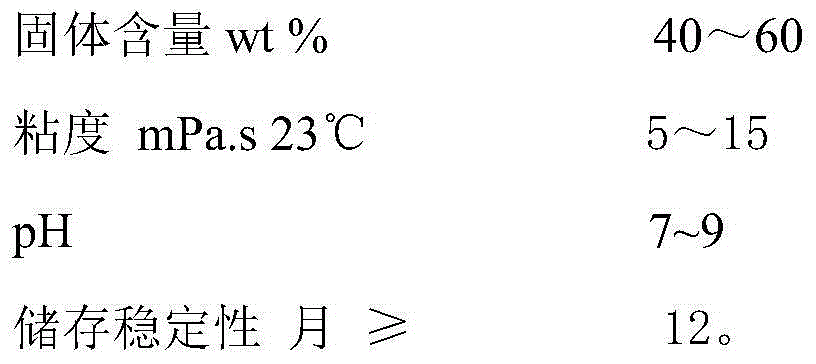

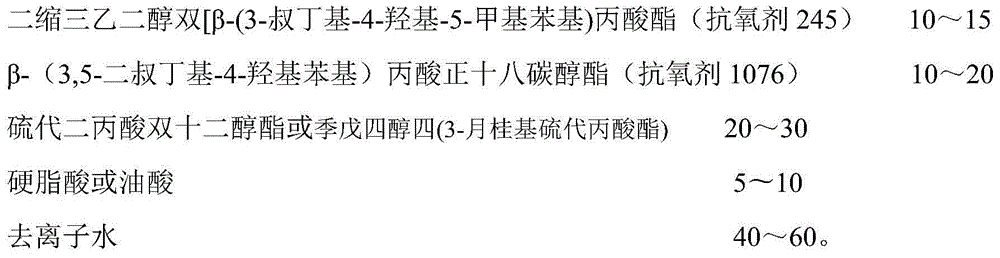

Method used

Image

Examples

Embodiment 1

[0056] Prepare the emulsion type composite antioxidant specially for MBS resin of the present invention according to the following steps

[0057] ①. Preparation of antioxidant suspension

[0058] Accurately weigh 10 parts by weight of triethylene glycol bis[β-(3-tert-butyl-4-hydroxyl-5-methylphenyl) propionate,

[0059] β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate 10 parts by weight, dilauryl thiodipropionate 20 parts by weight, stearic acid 5 parts by weight , and 55 parts by weight of deionized water, put into an antioxidant suspension reactor, stir, heat up to between 60-75°C, keep warm and stir for 10 minutes, and prepare an antioxidant suspension for subsequent use;

[0060] ②. Preparation of emulsion type composite antioxidant

[0061] Under stirring, slowly add 0.7 parts by weight of sodium hydroxide to step ① into the antioxidant suspension prepared in step ①, and continue to mix evenly under stirring at a temperature of 60-75°C; then, control the sti...

Embodiment 2

[0064] Prepare the emulsion type composite antioxidant specially for MBS resin of the present invention according to the following steps

[0065] ①. Preparation of antioxidant suspension

[0066] Accurately weigh 15 parts by weight of triethylene glycol bis[β-(3-tert-butyl-4-hydroxyl-5-methylphenyl) propionate,

[0067] 18 parts by weight of n-octadecyl β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate, 15 parts by weight of dilauryl thiodipropionate, 5.7 parts by weight of stearic acid , and 56.3 parts by weight of deionized water are put into an antioxidant suspension reaction kettle, under stirring, the temperature is raised to between 60~75° C., and the mixture is kept warm and stirred for 20 minutes to prepare an antioxidant suspension for subsequent use;

[0068] ②. Preparation of emulsion type composite antioxidant

[0069] Under stirring, slowly add 1.16 parts by weight of sodium hydroxide to step ① into the antioxidant suspension prepared in step ①, and continue to m...

Embodiment 3

[0072] Prepare the emulsion type composite antioxidant specially for MBS resin of the present invention according to the following steps

[0073] ①. Preparation of antioxidant suspension

[0074] Accurately weigh 20 parts by weight of triethylene glycol bis[β-(3-tert-butyl-4-hydroxyl-5-methylphenyl) propionate,

[0075] β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate 12 parts by weight, pentaerythritol tetrakis (3-lauryl thiopropionate) 20 parts by weight, oleic acid 8 Parts by weight and 40 parts by weight of deionized water are put into the antioxidant suspension reaction kettle, under stirring, the temperature is raised to between 60-75°C, and the mixture is kept warm and stirred for 30 minutes to prepare the antioxidant suspension. ;

[0076] ②. Preparation of emulsion type composite antioxidant

[0077] Under stirring, slowly add 1.12 parts by weight of potassium hydroxide to step ① into the antioxidant suspension prepared in step ①, and continue to mix ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com