Novel process for recycling waste leather-making liquid step by step

A waste liquid recycling and waste liquid technology, applied in application, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc. Coarse, "hairy surface" and other problems, to achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

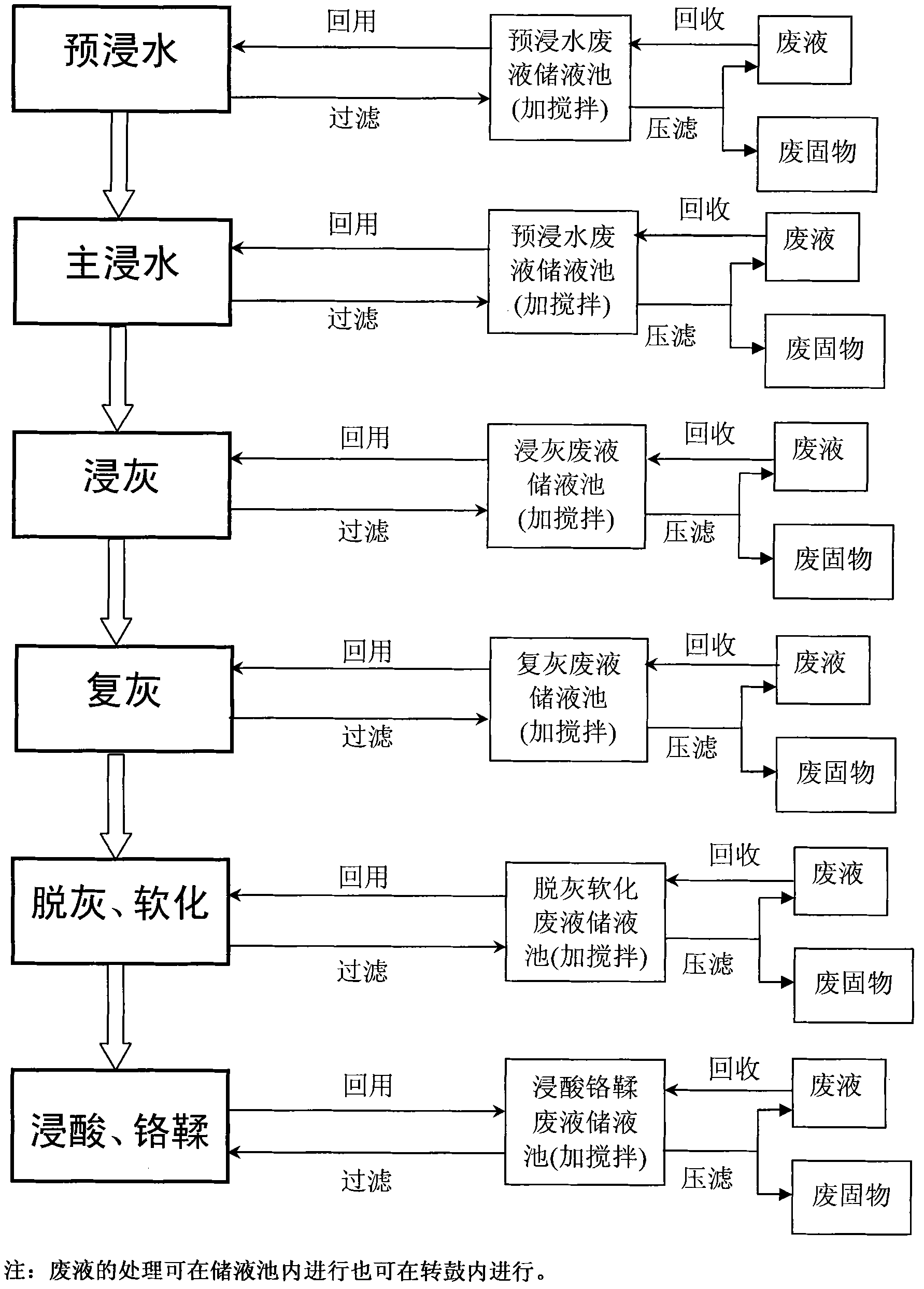

[0028] As shown in the figure, in the pre-soaking process, after the raw hide is pre-soaked, the waste liquid is filtered to remove solids and then discharged into the pre-soaked waste liquid storage tank, stirred evenly with a stirrer, and then pumped out by an alkali-resistant pump and discharged into the pre-soaked water. Soaking the drum, the process of pre-soaking with pre-soaked water waste liquid is: based on the weight of the original skin, add 200% of the pre-soaked water waste liquid, add 0.25% fungicide, rotate the drum for 15 minutes, and then add 0.35% soaking aid, 0.2% degreasing agent, the drum rotates for 20 minutes, stops for 40 minutes, combined with rotation and stop for 4 times, and the waste water after presoaking is discharged into the liquid storage tank. In the main immersion process, the main immersion waste liquid is filtered to remove solids and then discharged into the main immersion waste liquid storage tank, stirred evenly, then pumped out by an al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com