Production process of non-heavy metal tanned cow leather

A production process, heavy metal technology, applied in the field of tanning, to achieve the effect of eliminating swelling, high efficiency, and good softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

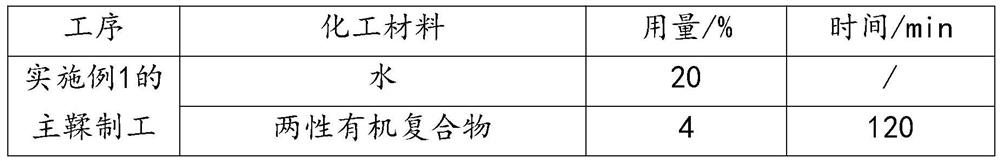

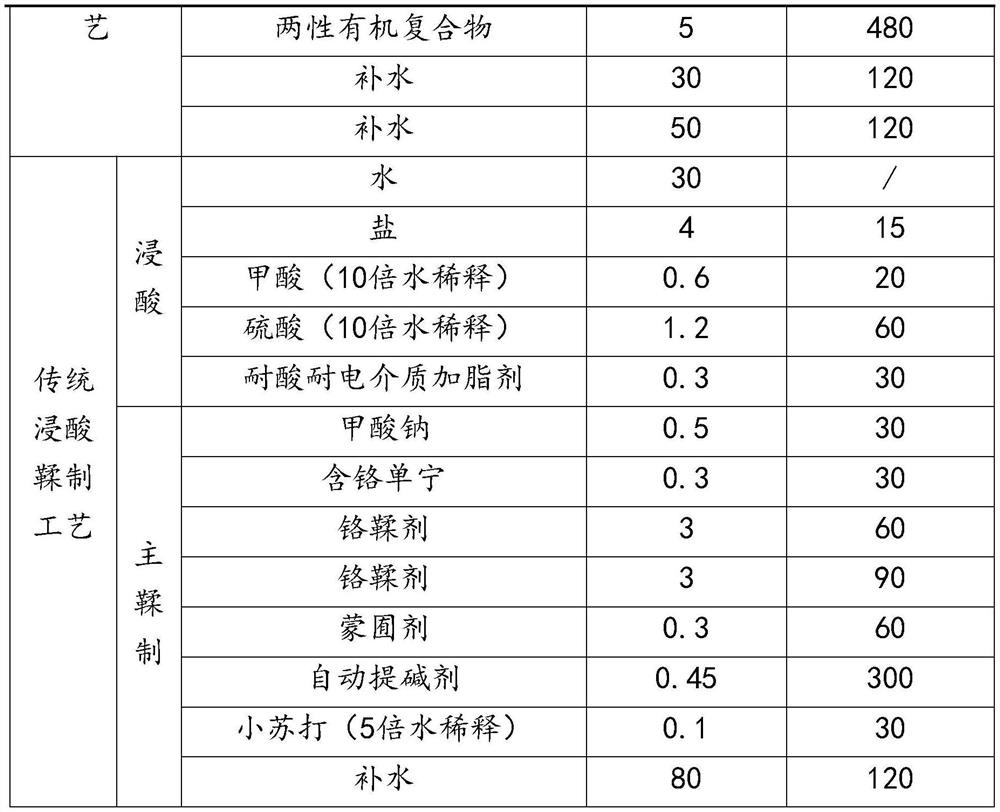

Embodiment 1

[0038] A production process for heavy metal-free tanned cow leather, comprising the following process flow:

[0039] (1) After weighing the gray hide, put the gray hide into the drum; (based on the weight of the gray hide, assuming that the gray hide is 1kg, then 0.1% degreasing agent, that is, 0.001kg of degreasing agent)

[0040] (2) Pre-deliming: Add 80% water, 0.1% degreasing agent Eusapon OC (BASF Chemical Company), 0.2% deliming agent Decaltal U (BASF Chemical Company) to the drum, temperature 30°C, rotate for 30min, bath liquid pH is 12;

[0041] (3) Main deliming: add 50% water, 0.1% degreasing agent Eusapon OC (BASF Chemical Company), 0.15% complexing agent TRUKALINK (Toppler Company), 2.5% deliming agent Decaltal U (BASF Chemical company), the temperature is 30°C, the rotation is 60min, and the pH of the bath solution is 8.5;

[0042] (4) Softening: carry out in the same bath as the main deliming process, add 0.15% trypsin DESOBATE U5 (Desobate Chemical Industry Co...

Embodiment 2

[0061] A production process for heavy metal-free tanned cow leather, comprising the following process flow:

[0062] (1) After weighing the gray bare hide, put the gray bare hide into the drum;

[0063] (2) Pre-deliming: Add 90% water, 0.13% degreasing agent Eusapon OC (BASF Chemical Company), 0.35% deliming agent Decaltal U (BASF Chemical Company) to the drum, temperature 30°C, rotate for 30min, bath liquid pH is 12;

[0064] (3) Main deliming: add 60% water, 0.13% degreasing agent Eusapon OC (Basf Chemical Company), 0.23% complexing agent TRUKALINK (Toppler Company), 2.75% deliming agent Decaltal U ( BASF chemical company), the temperature is 30°C, the rotation is 60min, and the pH of the bath solution is 8.5;

[0065] (4) Softening: carry out in the same bath as the main deliming process, add 0.23% trypsin DESOBATE U5 (Desobate Chemical Industry Co., Ltd.), rotate for 30min, and the pH of the bath solution is 8.5;

[0066] (5) Main tanning: add 25% water, 4.5% amphoteric...

Embodiment 3

[0084] A production process for heavy metal-free tanned cow leather, comprising the following process flow:

[0085] (1) After weighing the gray bare hide, put the gray bare hide into the drum;

[0086] (2) Pre-deliming: Add 100% water, 0.15% degreasing agent Eusapon OC (BASF Chemical Company), 0.5% deliming agent Decaltal U (BASF Chemical Company) to the drum, temperature 30°C, rotate for 30min, bath liquid pH is 12;

[0087] (3) Main deliming: add 70% water, 0.15% degreasing agent Eusapon OC (Basf Chemical Company), 0.3% complexing agent TRUKALINK (Toppler Company), 3% deliming agent Decaltal U ( BASF chemical company), the temperature is 30°C, the rotation is 60min, and the pH of the bath solution is 8.5;

[0088] (4) Softening: carry out in the same bath as the main deliming process, add 0.3% trypsin DESOBATE U5 (Desobate Chemical Industry Co., Ltd.), rotate for 30min, and the pH of the bath solution is 8.5;

[0089] (5) Main tanning: add 30% water, 5% amphoteric organi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tear load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com