An electric core pole piece group fixing frame and a battery with the battery pole piece group fixing frame

A pole piece group and fixing frame technology, which is applied in battery pack components, secondary battery manufacturing, circuits, etc., can solve the problems of reducing the performance of power batteries in groups, affecting the consistency of battery production, and dislocation of battery pole pieces. , to achieve efficient assembly process and production consistency, excellent battery performance, and eliminate swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

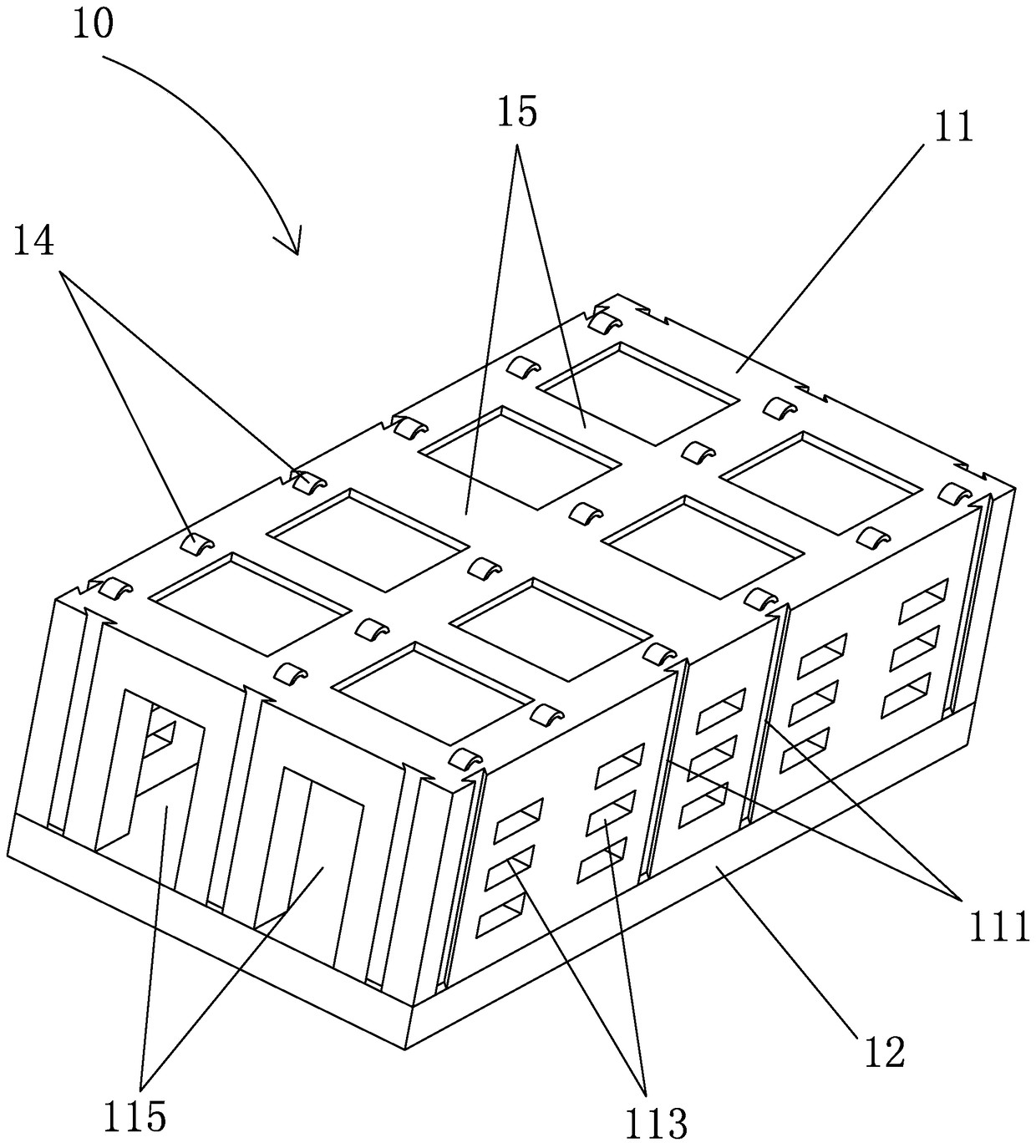

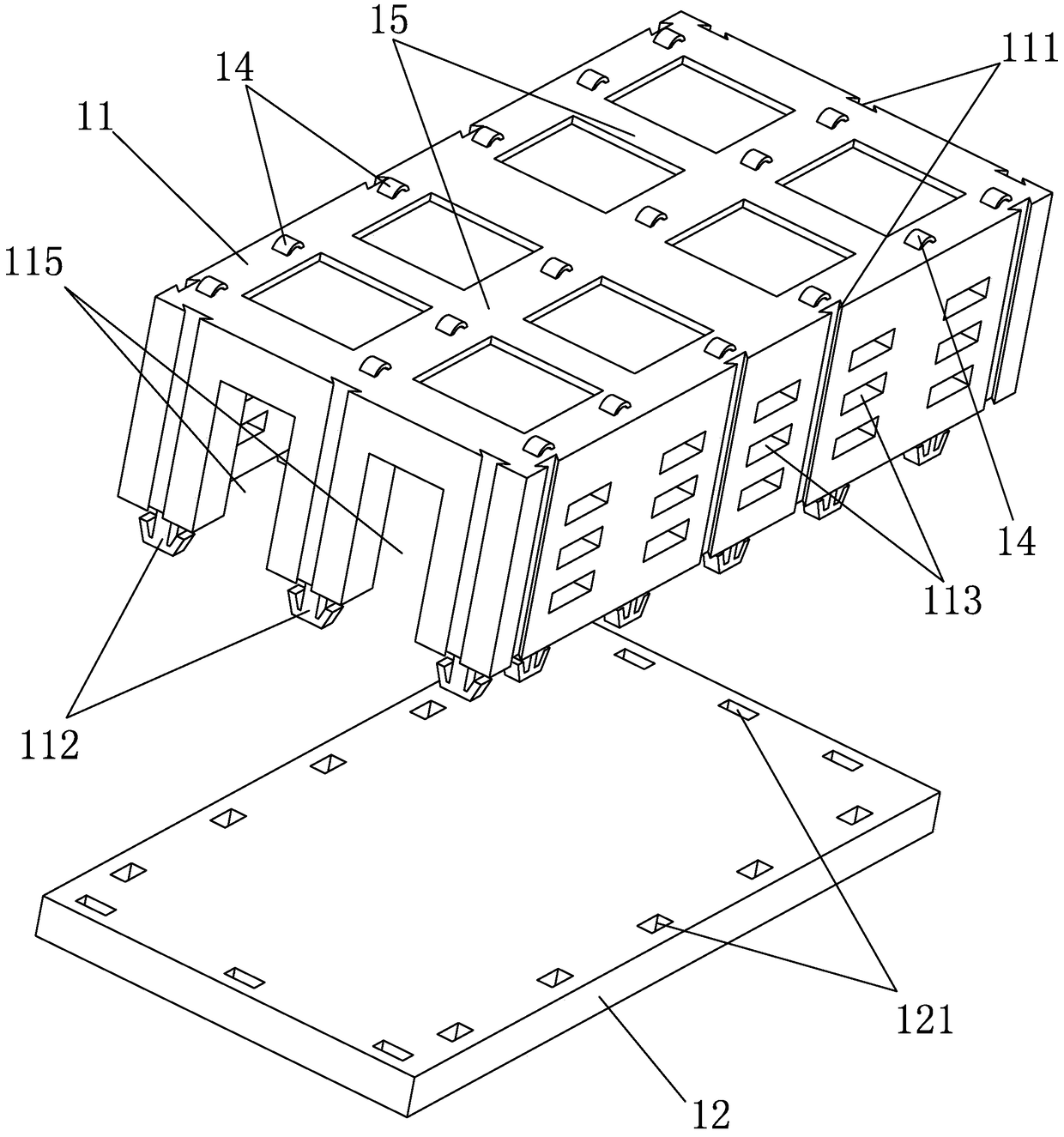

[0039] Figure 1 to Figure 7 An embodiment of a battery pole piece group fixing frame is given.

[0040] Such as Figure 1 to Figure 7 As shown, the battery pole piece group fixing frame 10 of this example includes an upper cover 11 and a bottom plate 12 , elastic sheets 14 and reinforcing ribs 15 are provided on the upper surface of the upper cover 11 and the lower surface of the bottom plate 12 . The upper cover 11 is provided with a grasping insertion hole 111 and a through hole 113 .

[0041] In this example, the grasping jack 111 is a dovetail groove structure, such as figure 2 , image 3 and Figure 7 shown.

[0042] In this example, the lug outlet 115 of the upper cover 11 is arranged on the same side, as image 3 shown.

[0043]In this example, the connection mode between the upper cover 11 and the bottom plate 12 is a snap connection, and the upper cover 11 is provided with a hasp hook 112 matching with the hasp lock hole 121 of the bottom plate 12 . The edge...

Embodiment 2

[0049] Figure 8 ~ Figure 13 Provides another embodiment of the cell pole piece group fixing frame.

[0050] The difference between this example and Example 1 is:

[0051] In this example, the lug outlet 115 of the upper cover 11 is arranged on the opposite side, as Figure 8 and Figure 11 shown.

[0052] In this example, the upper cover 11 and the bottom plate 12 are connected by an external clamping device. The upper cover 11 is provided with an upper cover clamping step 114 that facilitates the clamping connection of the external clamping device 16. The bottom plate clamping step 123 of device 16 clamping connection, as Figure 10 , Figure 11 and Figure 12 shown.

[0053] In this example, the through hole 113 of the loam cake 11 is circular, as Figure 8 and Figure 12 shown.

[0054] In this example, the lower surface of the base plate 12 is provided with a base plate concave hole 122, such as Figure 9 , Figure 13 shown.

[0055] In this example, the shap...

Embodiment 3

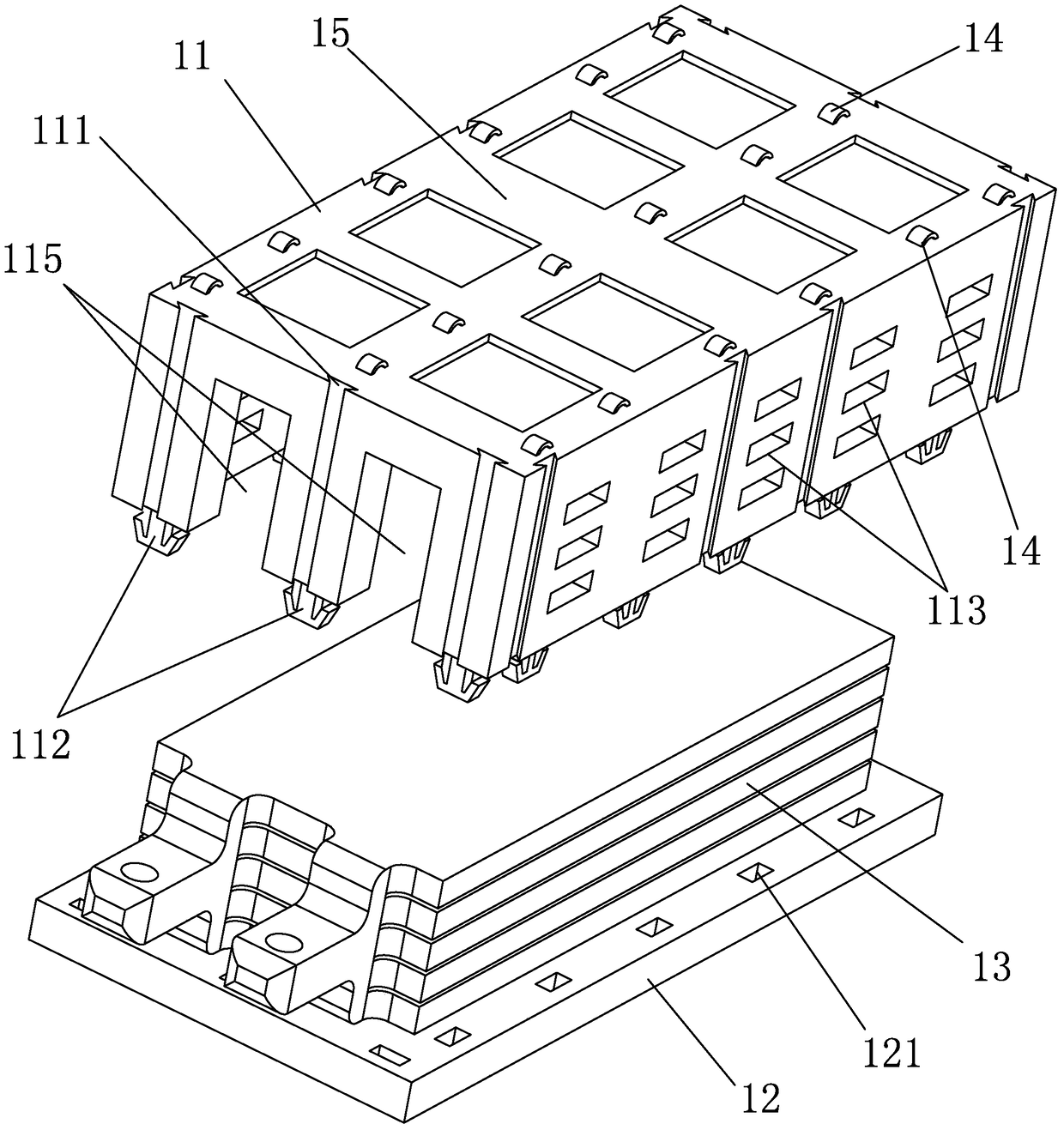

[0059] Figure 14 An embodiment of a battery with the battery pole piece group fixing frame is given.

[0060] The battery of this example includes a cell pole piece set 13 and a battery casing 20 , and the battery of this example also has a battery pole piece set fixing frame as described in Embodiment 1.

[0061] In this example, the thickness of the cell pole piece group 13 is 80 mm.

[0062] The technical scheme of the present invention can not only keep the cell pole piece group inside the battery in a compressed state, but also prevent the battery pole pieces from being dislocated and the distance between them increased during the production and assembly process of the battery pole piece group, and reduce the internal resistance of the battery , and can eliminate the expansion of the cell pole piece group caused by the expansion and contraction of the electrode material lattice inside the battery, and prevent the expansion and deformation of the battery case, so that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com