Reutilization method of chromium-containing leather production sludge

A technology of chromium sludge and chromium slurry, which is applied in the fields of sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. with thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

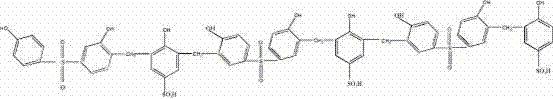

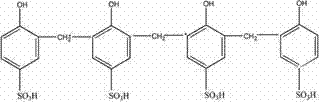

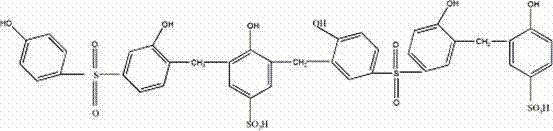

Image

Examples

Embodiment 1

[0023] Put 2000kg of chromium-containing sludge from tannery into 680kg of dilute sulfuric acid with a concentration of 55% for dissolution, then slowly heat up to 80-90°C and stir for 4 hours to hydrolyze, cool down to 30-40°C, and filter through plate and frame to obtain filtrate 2620kg and filter residue 60kg.

[0024] Put 280kg of red alum sodium into the obtained 2620kg of filtrate, then slowly raise the temperature to 90-100°C, and keep stirring at 90-100°C for 2 hours. After the heat preservation is completed, drop the temperature to 80-85°C and add dropwise Add 140kg of starch sugar aqueous solution, drop it for about 1 hour, reduce hexavalent chromium to trivalent chromium, keep stirring at 95-100°C for 1 hour after dropping, check and control the residual amount of hexavalent chromium to not exceed 2mg / kg, Then lower the temperature to 40-60°C to obtain 3000kg of chrome slurry solution.

[0025] Take 2640kg of chrome slurry solution and carry out spray drying betwee...

Embodiment 2

[0029] Put 2000kg of chromium-containing sludge from tannery into 1000kg of dilute sulfuric acid with a concentration of 55% for dissolution, then slowly raise the temperature to 70-80°C and stir for 3 hours to hydrolyze, cool down to 40-50°C and filter through plate and frame to obtain the filtrate 2940kg and filter residue 60kg.

[0030] Put 350kg of red alum sodium into the obtained 2940kg filtrate, then slowly raise the temperature to 90-100°C, and keep stirring at 90-100°C for 2 hours. After the heat preservation is completed, drop the temperature to 80-85°C and add dropwise Add 170kg of starch sugar aqueous solution, drop it for about 1 hour, reduce hexavalent chromium to trivalent chromium, keep stirring at 95-100°C for 1 hour after dropping, check and control the residual amount of hexavalent chromium to not exceed 2mg / kg, Then lower the temperature to 40-60°C to obtain about 3460kg of chrome slurry solution.

[0031] Take 2660kg of chrome slurry solution and spray-dr...

Embodiment 3

[0035] Put 2000kg of chromium-containing sludge from tannery into 2000kg of dilute sulfuric acid with a concentration of 55% for dissolution, then slowly raise the temperature to 60-70°C, stir and hydrolyze for 3 hours, cool down to 40-50°C, and filter through plate and frame to obtain the filtrate 3940kg and filter residue 60kg.

[0036] Put 900kg of sodium red alum into the obtained 3940kg filtrate, then slowly raise the temperature to 90-100°C, keep stirring at 90-100°C for 2 hours, drop the temperature at 80-85°C after the heat preservation is completed, and add 50% of the mass content dropwise Starch sugar aqueous solution 450kg, add dropwise for about 1 hour, reduce hexavalent chromium to trivalent chromium, keep stirring at 95-100°C for 1 hour after dropwise addition, check and control the residual amount of hexavalent chromium to not exceed 2mg / kg, Then lower the temperature to 40-60°C to obtain about 5290kg of chrome slurry solution.

[0037] Take 4290kg of chrome sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com