Preparation method of amphoteric retanning fatliquor

A retanning fatliquoring and amphoteric technology is applied in the field of preparation of amphoteric retanning and fatliquoring agents, which can solve the problems of insufficient alkali resistance and electrolytic resistance, restricting applications, etc., and achieve the effects of avoiding the release of VOC and improving the absorption rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

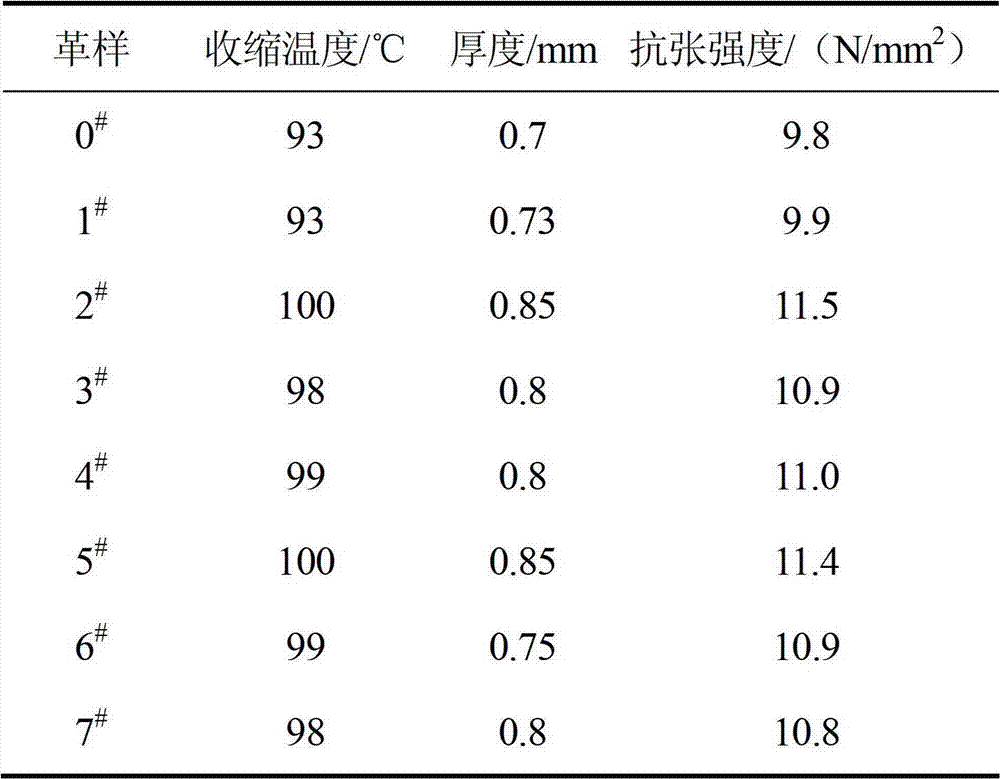

Image

Examples

Embodiment 1

[0022] A preparation method of an amphoteric retanning fatliquoring agent, comprising the following steps:

[0023] The first step, amidation modification of oil:

[0024] Add 950 parts by mass of natural animal and vegetable oils, 61 parts by mass of monoethanolamine and 5.1 parts by mass of the first catalyst into a reactor equipped with a stirrer and a thermometer, and after mixing uniformly, heat up to 130°C. React for 4 hours to obtain system A, the natural animal and vegetable oil is rapeseed oil, and the first catalyst is sodium methylate;

[0025] The second step, esterification modification:

[0026] Add 196 parts by mass of maleic anhydride and 6 parts by mass of the second catalyst to system A, mix evenly and then raise the temperature to 120°C for 2 hours, cool down to 50°C after the reaction, and use a base with a mass concentration of 20% The neutralization system pH of the alkaline aqueous solution is 7.0 to obtain system B, the second catalyst is p-toluenesul...

Embodiment 2

[0030] A preparation method of an amphoteric retanning fatliquoring agent, comprising the following steps:

[0031] The first step, amidation modification of oil:

[0032] Add 950 parts by mass of natural animal and vegetable oils, 122 parts by mass of monoethanolamine and 5.4 parts by mass of the first catalyst into a reactor equipped with a stirrer and a thermometer, and after mixing uniformly, heat up to 150°C. React for 3 hours to obtain system A, the natural animal and vegetable oil is linseed oil, and the first catalyst is sodium methylate;

[0033] The second step, esterification modification:

[0034] Add 392 parts by mass of maleic anhydride and 7.3 parts by mass of the second catalyst to system A, mix uniformly and then raise the temperature to 90°C for 4 hours, cool down to 60°C after the reaction, and use a base with a mass concentration of 30% The neutralization system pH of the alkaline aqueous solution is 7.0 to obtain system B, the second catalyst is sulfuric...

Embodiment 3

[0038] A preparation method of an amphoteric retanning fatliquoring agent, comprising the following steps:

[0039] The first step, amidation modification of oil:

[0040] Add 950 parts by mass of natural animal and vegetable oil, 100 parts by mass of monoethanolamine and 5.3 parts by mass of the first catalyst into a reactor equipped with a stirrer and a thermometer, and after mixing uniformly, heat up to 140°C. Reaction 3h, obtain system A, described natural animal and vegetable oil is castor oil, described first catalyst is sodium hydroxide;

[0041] The second step, esterification modification:

[0042] Add 321 parts by mass of maleic anhydride and 6.9 parts by mass of the second catalyst to system A, mix them uniformly, then raise the temperature to 110°C for 3 hours, cool down to 50°C after the reaction, and use a base with a mass concentration of 25% The neutralization system pH of the alkaline aqueous solution is 7.0, and the system B is obtained, the second catalyst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com