Integrated commutator detector and detection method thereof

A detection device and commutator technology, applied to measuring devices, instruments, etc., can solve the problems of poor detection reliability and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

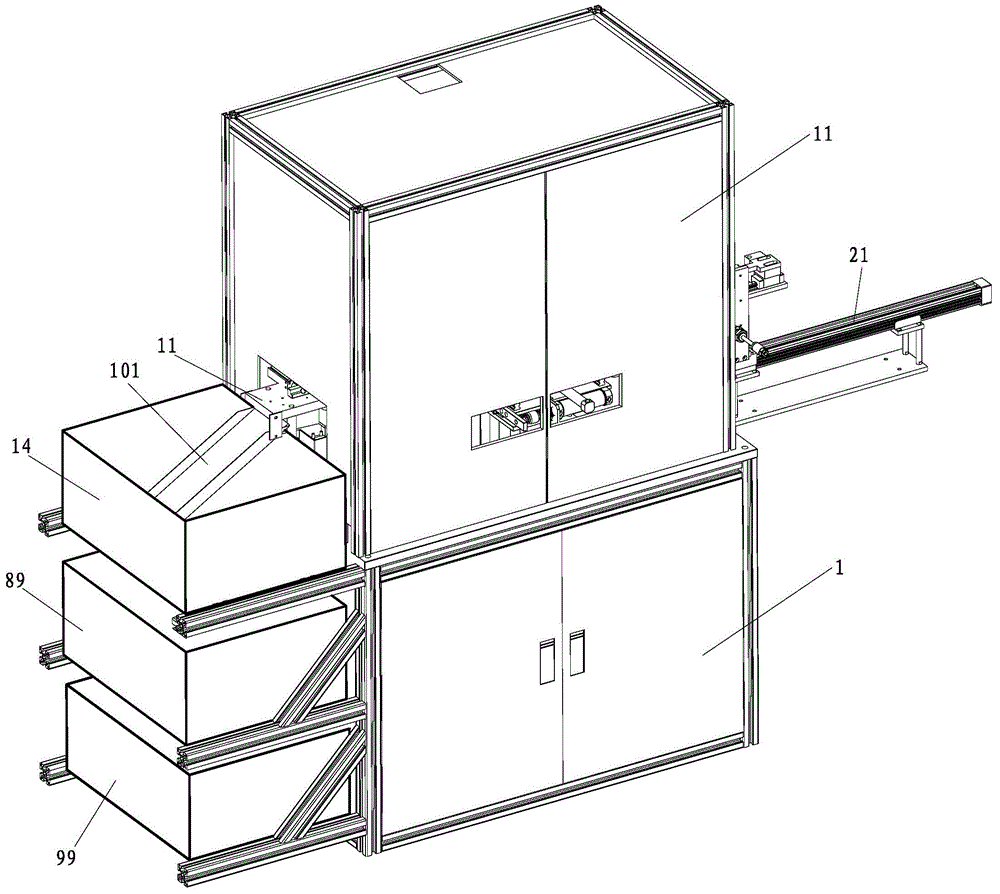

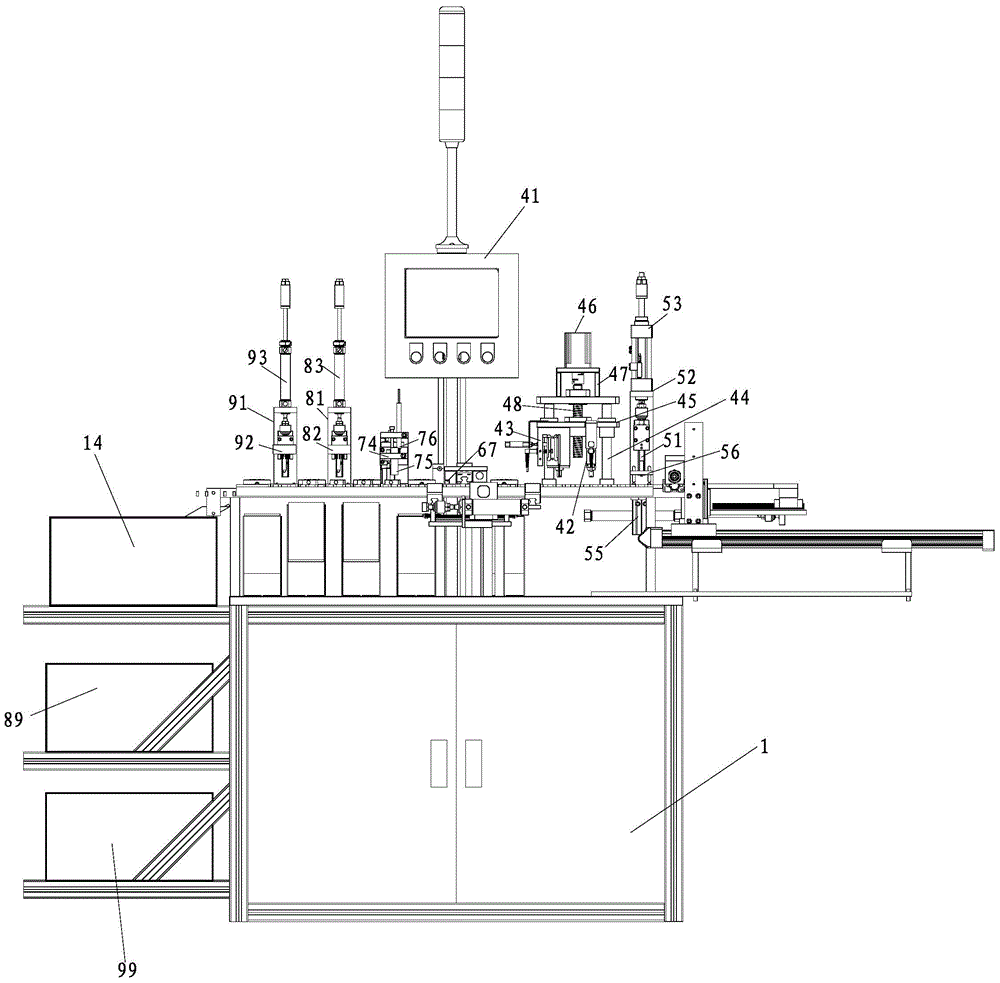

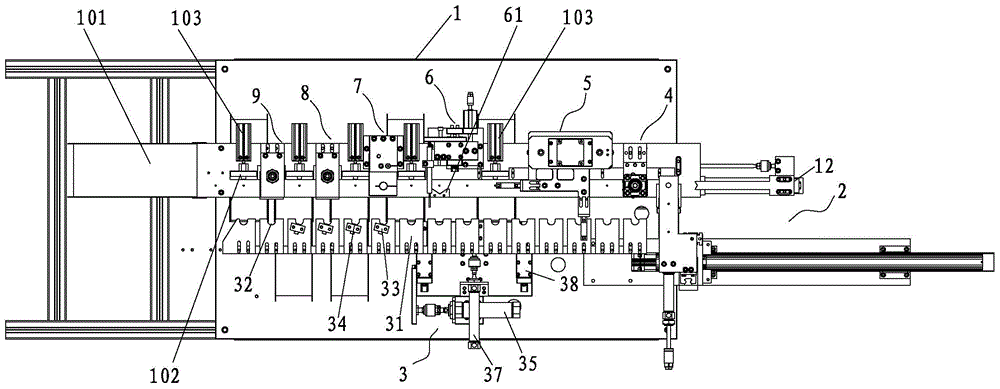

[0058] Such as Figure 1-3 As shown, the integrated commutator aperture detection device includes a base 1, and a feeding mechanism 2, a transfer mechanism 3, a go-no-go gauge detection mechanism 5, an inner diameter detection mechanism 4, an outer diameter detection mechanism 6, Height detection mechanism 7, inter-sheet high-voltage detection mechanism 8, film shaft high-pressure detection mechanism 9, and discharge mechanism 10. The base 1 is further provided with an outer cover 13 to prevent dust and water vapor from entering each detection mechanism and affecting the detection effect. The work platform 11 of the base 1 is respectively provided with a go-no-go gauge detection station, an inner diameter detection station, an outer diameter detection station, a height detection station, and an inter-chip high-voltage resistance detection station corresponding to the above-mentioned various detection mechanisms. And film shaft high pressure detection station. The detection de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com