Plastic sucking production line and production process thereof

A production line and blister forming technology, applied in the field of blister production line and its production process, can solve the problems of high labor intensity of production workers, single product model and specification, and low degree of equipment automation, so as to reduce heat dissipation and easy operation The effect of fast and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

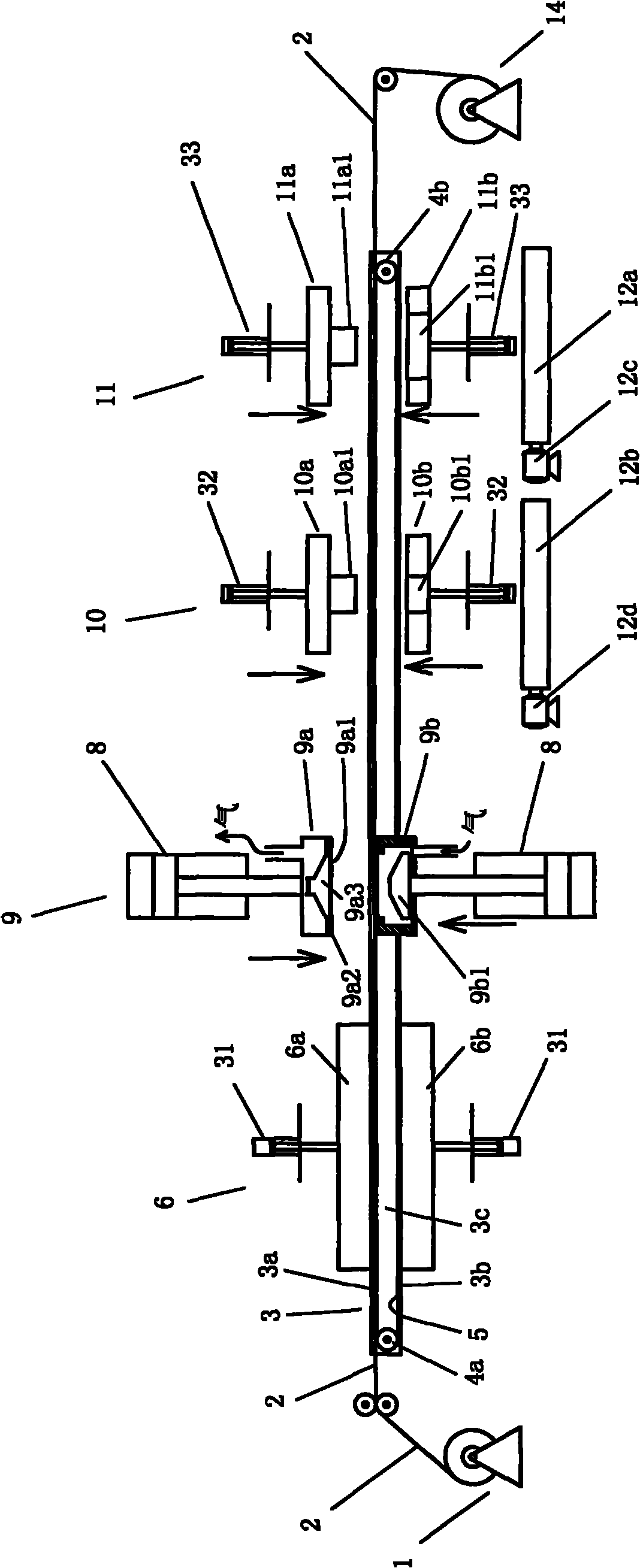

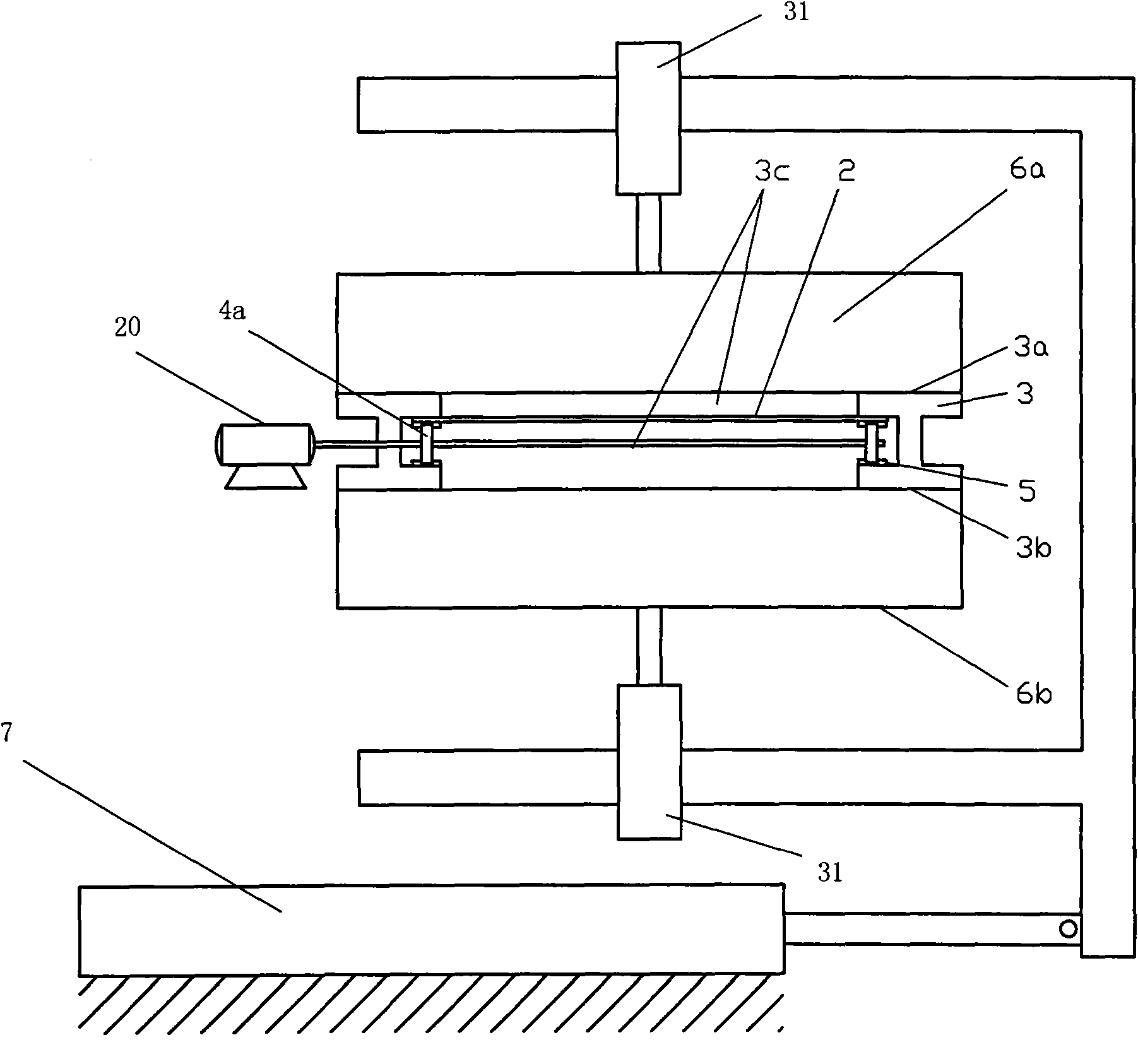

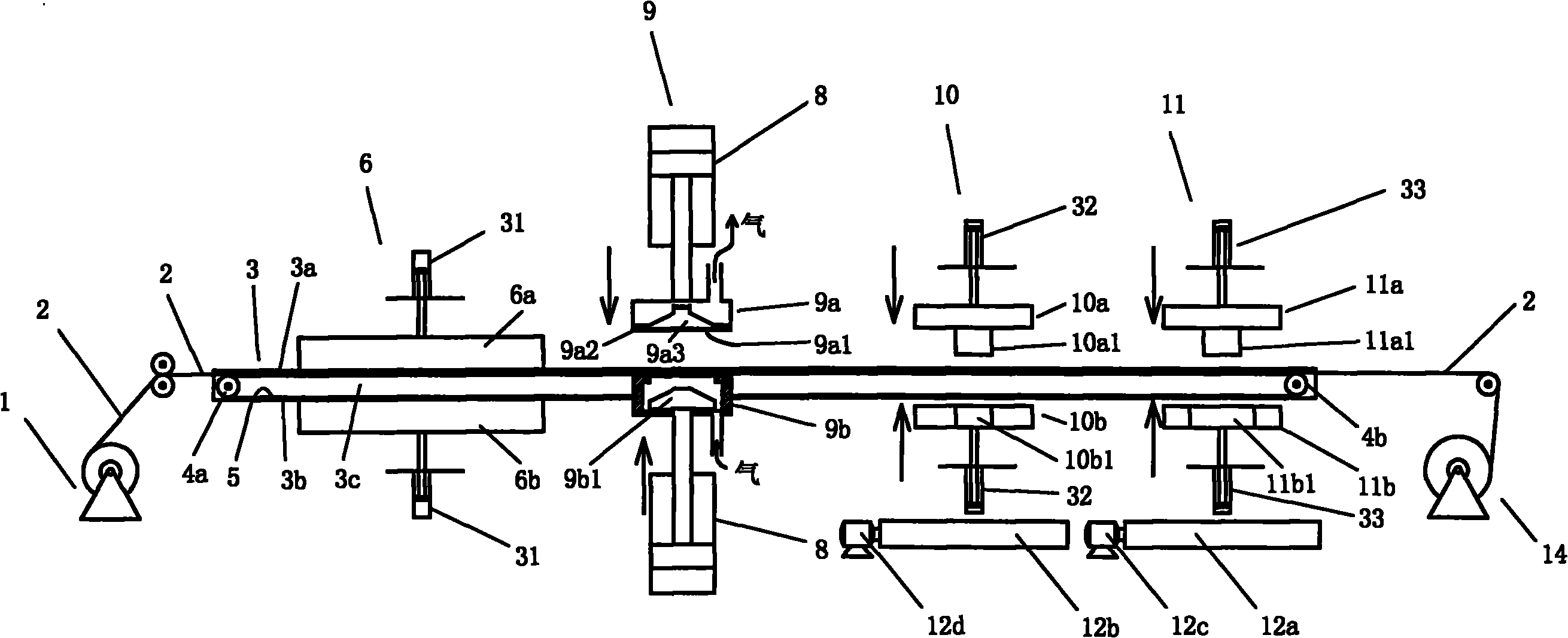

[0026] The present invention will be further described below with specific embodiment, see Figure 1-2 :

[0027] A blister production line, on one side of two guide rails 3 that are parallel to each other and have openings on the opposite side, a feeding rack 1 is arranged, and a receiving rack 14 is arranged on the other side, and the opening of each guide rail 3 is correspondingly arranged There is a circular conveying device 5 for conveying the sheet material 2, and a heating oven 6, a blister forming and in-mold punching device 9 and a stacking device are arranged in sequence between the two guide rails 3 from the feeding rack 1 to the receiving rack 14 Device 11, heating oven 6, blister forming and in-mold punching device 9, upper and lower parts of stacking device 11 are arranged on the upper and lower sides of guide rail 3 and are driven by oil cylinder 8 or cylinder 31, 32, 33 to move up and down to realize heating, Forming, punching and stacking, a first endless con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com