Assembled type tunnel kiln

A tunnel kiln and prefabricated technology, which is applied in the field of kilns for sintering bricks and tiles, can solve the problems of construction personnel safety threats, low safety factor, inconvenient installation and construction, etc., to increase the degree of automation control, avoid safety threats, shorten The effect of production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

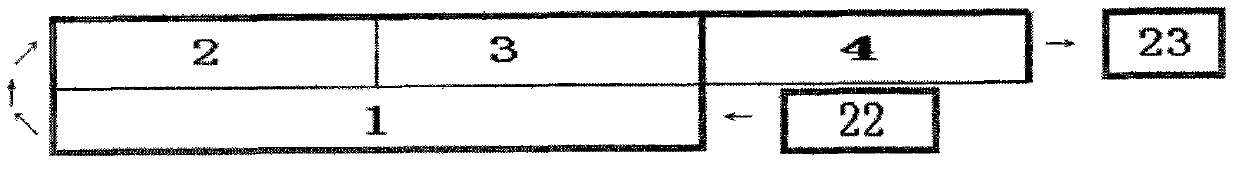

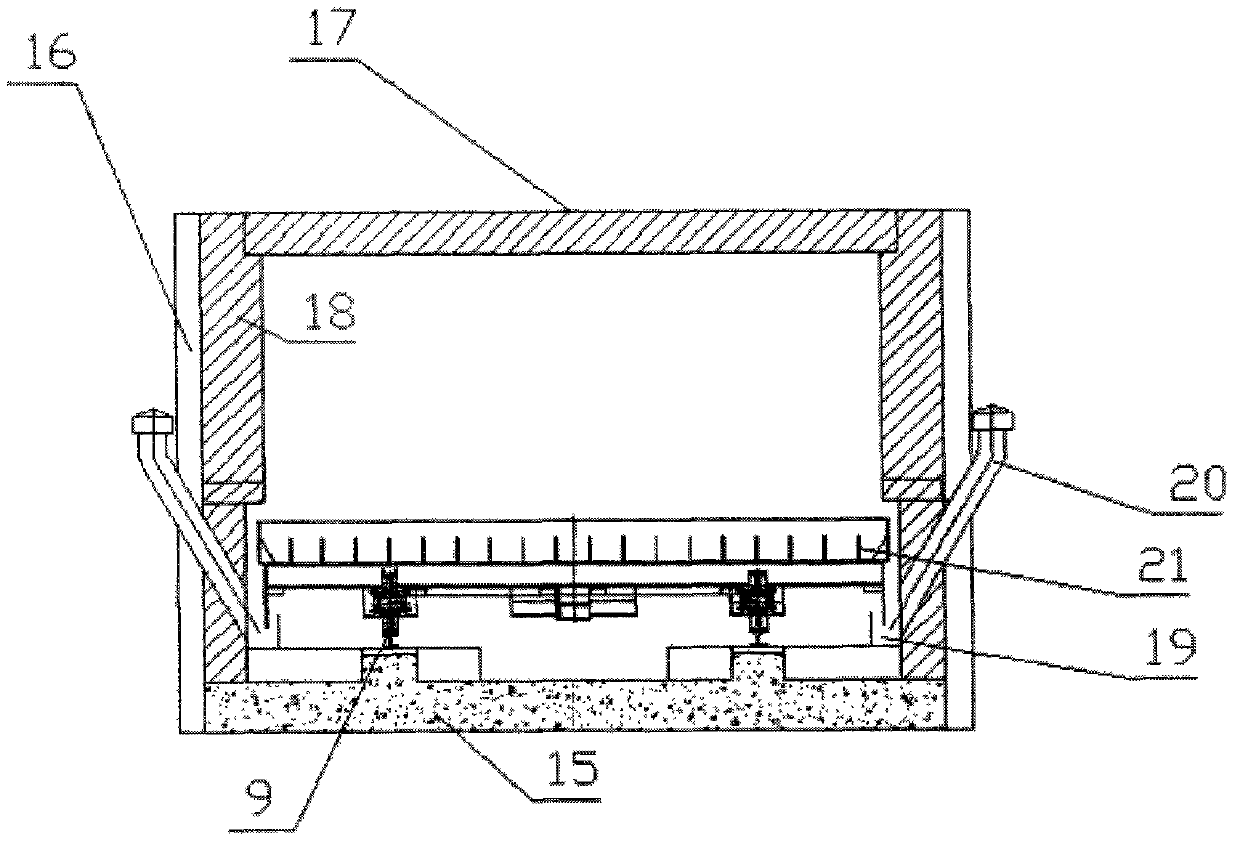

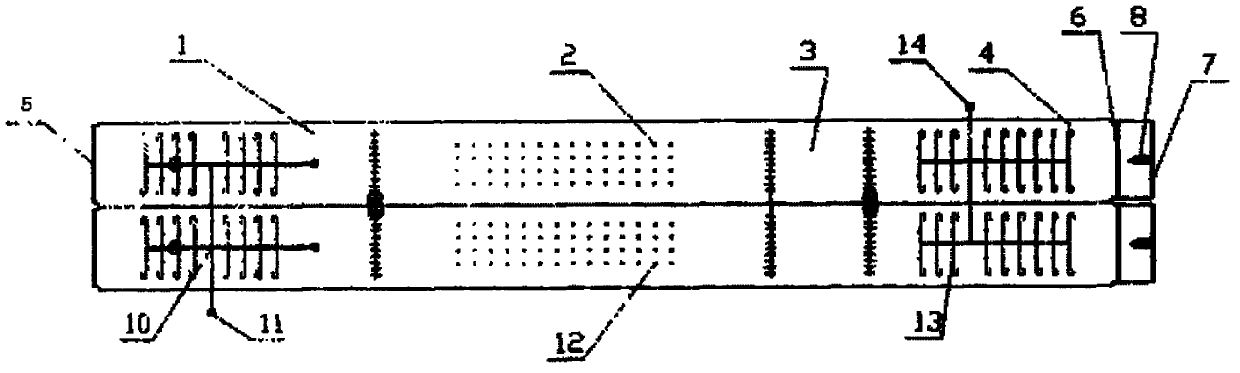

[0022] Such as figure 1 and image 3 As shown in , a prefabricated tunnel kiln includes a bottom foundation 15, a steel structure kiln wall 16, a kiln roof 17 and a heat-insulating fireproof layer 18, and the two sides of the bottom foundation 15 are fixedly provided with a steel structure kiln wall 16, A heat-insulating and fire-proof layer 18 is arranged inside the steel structure kiln wall 16, a kiln roof 17 is arranged on the top of the steel structure kiln wall 16, and the kiln car track 9 is set on the bottom foundation 15; on both sides of the kiln car track 9 A sand sealing groove 19 is provided, and a sand feeding pipe 20 is provided through the kiln wall 16 and the heat insulation and fire prevention layer 18 , and the sand feeding pipe 20 communicates with the sand sealing groove 19 . Both the heat insulation and fireproof layer 18 and the kiln roof 17 are made of ceramic fiber. The kiln roof 17 is flat. The prefabricated tunnel kiln is divided into sequentially ...

Embodiment 2

[0024] Such as figure 2 and image 3 As shown in , a prefabricated tunnel kiln includes a bottom foundation 15, a steel structure kiln wall 16, a kiln roof 17 and a heat-insulating fireproof layer 18, and the two sides of the bottom foundation 15 are fixedly provided with a steel structure kiln wall 16, A heat-insulating and fire-proof layer 18 is arranged inside the steel structure kiln wall 16, a kiln roof 17 is arranged on the top of the steel structure kiln wall 16, and the kiln car track 9 is set on the bottom foundation 15; on both sides of the kiln car track 9 A sand sealing groove 19 is provided, and a sand feeding pipe 20 is provided through the kiln wall 16 and the heat insulation and fire prevention layer 18 , and the sand feeding pipe 20 communicates with the sand sealing groove 19 . Both the heat insulation and fireproof layer 18 and the kiln roof 17 are made of ceramic fiber. The kiln roof 17 is flat; the assembled tunnel kiln is divided into a drying section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com