Heat-conducting composite material, rubber composition, pipe material for cooling media and preparation method for pipe material

A technology of heat-conducting composite materials and rubber compositions, which is applied in the fields of pipes for cooling media and their preparation, rubber compositions, and heat-conducting composite materials. Sticking or foaming, improving construction performance, and reducing the effect of vulcanization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

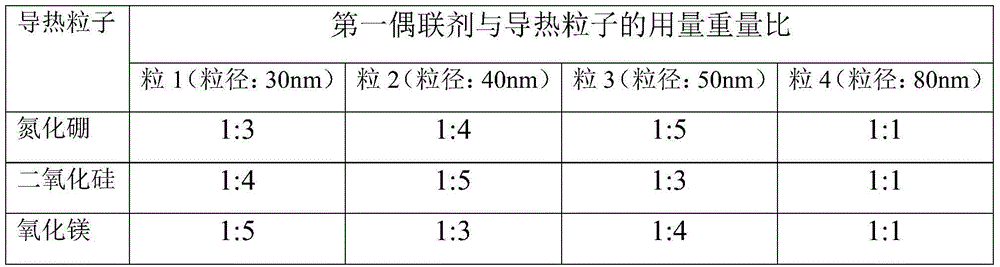

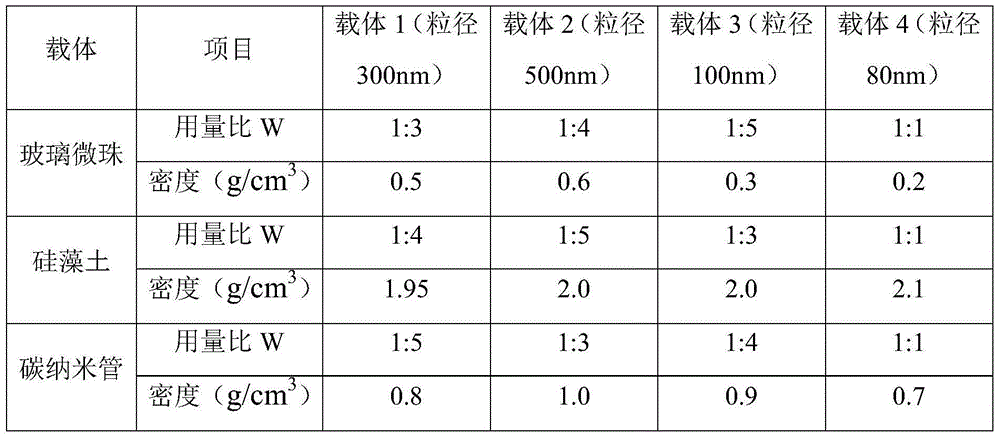

[0038] In the above method provided by the present invention, the thermally conductive particles surface-treated with the first coupling agent can be prepared by referring to conventional methods in the prior art, as long as the first coupling agent is made to sufficiently treat the surface of the thermally conductive particles, so that the first coupling agent It only needs to have good compatibility between the thermally conductive particles surface-treated with the coupling agent, the carrier surface-treated with the second coupling agent, and the rubber material. The preparation method of the thermally conductive particles surface-treated by the coupling agent comprises: stirring and mixing the conductive particles and the first coupling agent in proportion (preferably, the stirring speed in the stirring and mixing step is 3000-5000r / min, and the stirring time is 20min-30min), After standing (preferably the standing time in the standing step is 45-90min), the conductive par...

Embodiment 1 to 5

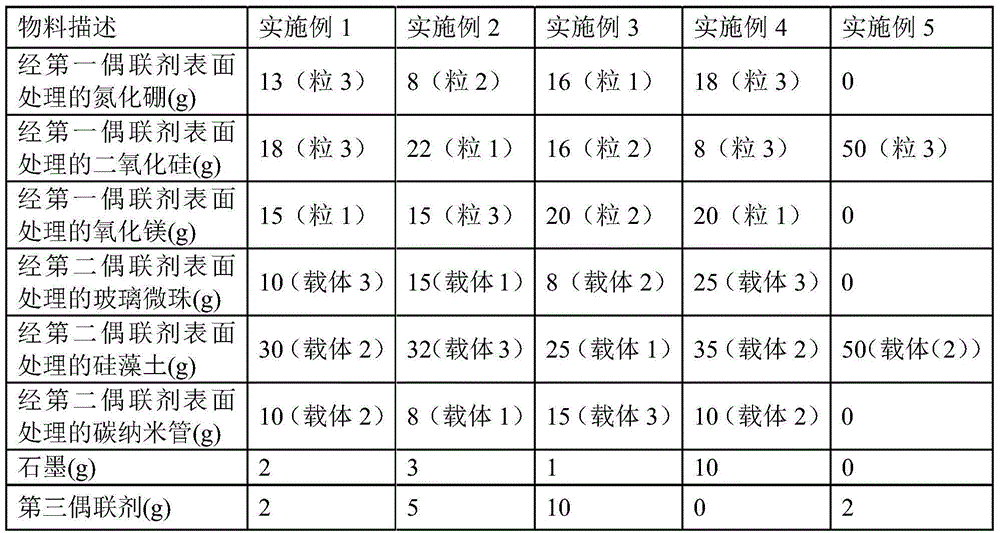

[0082] (1) Raw materials and ratio:

[0083] The raw materials and proportions of thermally conductive composite materials are shown in Table 3. Among them, the thermally conductive particles surface-treated with the first coupling agent are the corresponding particles in Table 1, the carriers surface-treated with the second coupling agent are the corresponding carriers in Table 2, and the third coupling agent is commercially available from Jianghan Fine Chemicals Co., Ltd. The company's JH-V173 model vinyl silane coupling agent.

[0084] table 3.

[0085]

[0086] (2) the preparation method of embodiment 1 to 5 is as follows:

[0087] The thermally conductive particles surface-treated with the first coupling agent, the carrier surface-treated with the second coupling agent, and the optional third coupling agent are ball-milled, the ball-milling speed is 4000r / min, and the ball-milling time is 25min, to obtain the Thermally conductive composites.

Embodiment 6

[0090] The raw materials and proportions of the thermally conductive composite material refer to Example 1, wherein the first coupling agent, the second coupling agent and the third coupling agent are commercially available A-151 vinyl silane coupling agents from United Carbon Corporation. joint agent;

[0091] Preparation method of thermally conductive composite material:

[0092] The conductive particles and the first coupling agent are stirred and mixed in proportion, the stirring speed is 3000r / min, and the stirring time is 30min. After standing for 90min, the conductive particle mixture is obtained, and the conductive particle mixture is ball-milled, and the ball-milling speed is 3000r / min. The time is 30 min, and the conductive particles surface-treated by the coupling agent are obtained.

[0093] The carrier and the second coupling agent are stirred and mixed in proportion, the stirring speed is 3000r / min, the stirring time is 30min, the carrier mixture is obtained aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com