Polyethylene-vinyl acetate hot-melt adhesive and preparation method thereof

A technology of vinyl acetate heat and vinyl acetate, applied in the direction of adhesives, graft polymer adhesives, polyurea/polyurethane adhesives, etc., can solve the problem of decreased peel strength, high content of inorganic fillers, difficult to apply to vehicles Interior glue and other problems, to achieve the effect of improving stability, stable performance, high bonding ability and chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Metal-adhesive EVA-based hot-melt adhesive and its preparation

[0030] (1) Raw materials:

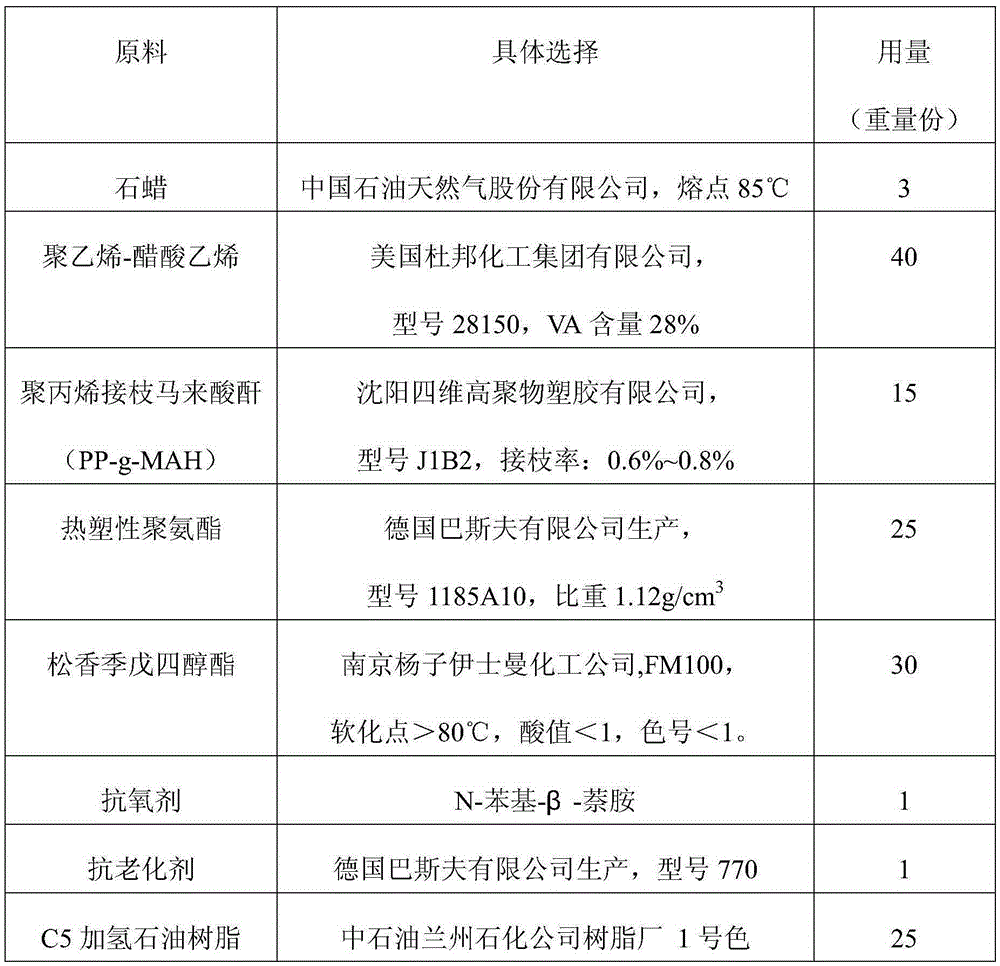

[0031] The ratio of raw materials in this example is shown in Table 1.

[0032] Table 1

[0033]

[0034] (2) Preparation method:

[0035] a: Heat 1 / 2 to 2 / 3 polyethylene-vinyl acetate and thermoplastic polyurethane to 140-160°C, add paraffin wax and antioxidant in proportion, after it melts, add the remaining polyethylene-vinyl acetate and thermoplastic polyurethane , to ensure that the system temperature is ≥130°C;

[0036] b: Add polypropylene grafted maleic anhydride (PP-g-MAH) in proportion to ensure that the system temperature is ≥120°C. After it melts, add rosin pentaerythritol ester and C5 hydrogenated petroleum resin, and cool down to 90-110°C. After it melts, heat and stir for 10 to 30 minutes, add an anti-aging agent, and discharge to obtain a metal-adhesive EVA-based hot-melt adhesive.

[0037] Both step a and step b are carried out at a vacuum ...

Embodiment 2

[0050] Embodiment 2: Metal-adhesive EVA-based hot-melt adhesive and its preparation

[0051] (1) Raw materials:

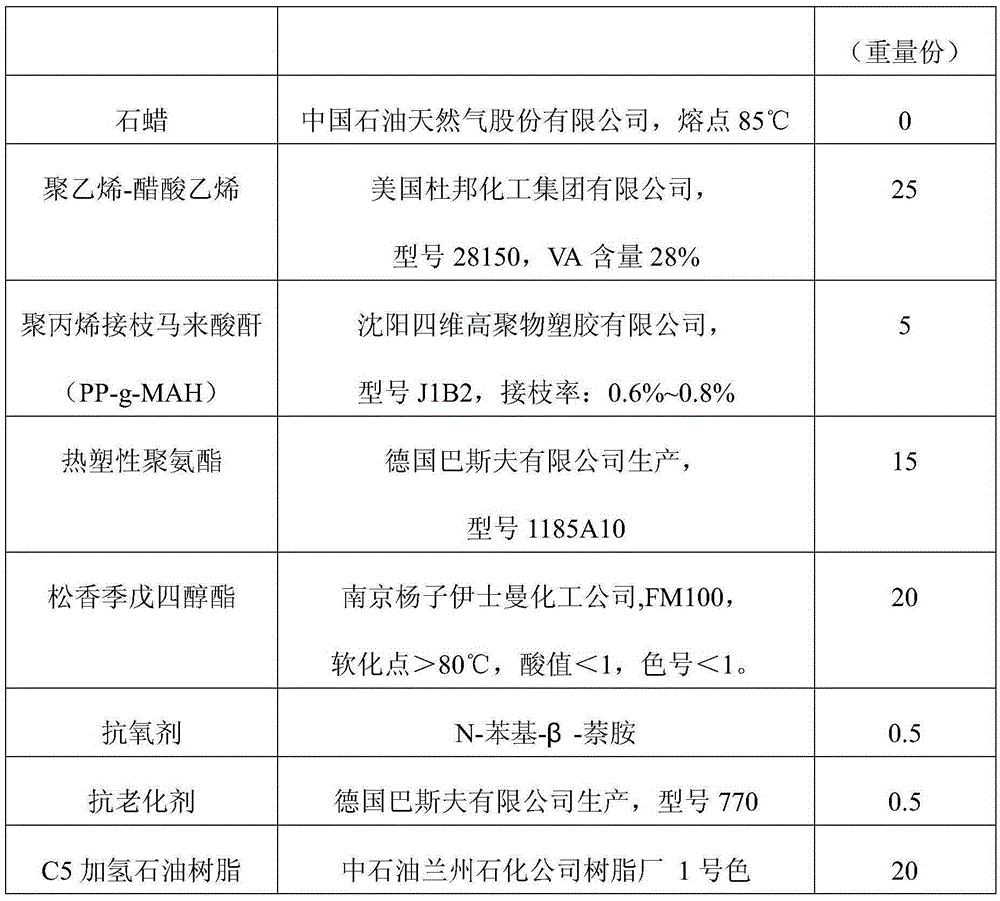

[0052] The ratio of raw materials in this example is shown in Table 2.

[0053] Table 2

[0054]

[0055]

[0056] (2) Preparation method:

[0057] a: Heat 1 / 2 to 2 / 3 polyethylene-vinyl acetate and thermoplastic polyurethane to 140-160°C, add antioxidant in proportion, after it melts, add the remaining polyethylene-vinyl acetate and thermoplastic polyurethane to ensure System temperature ≥ 130°C;

[0058] b: Add polypropylene grafted maleic anhydride (PP-g-MAH) in proportion to ensure that the system temperature is ≥120°C. After it melts, add rosin pentaerythritol ester and C5 hydrogenated petroleum resin, and cool down to 90-110°C. After it melts, heat and stir for 10 to 30 minutes, add an anti-aging agent, and discharge to obtain a metal-adhesive EVA-based hot-melt adhesive.

[0059] Both step a and step b are carried out at a vacuum degree of 0.1-0.5 ...

Embodiment 3

[0072] Embodiment 3: Metal-adhesive EVA-based hot-melt adhesive and its preparation

[0073] (1) Raw materials:

[0074] The ratio of raw materials in this example is shown in Table 3.

[0075] table 3

[0076]

[0077]

[0078] (2) Preparation method:

[0079] a: Heat 1 / 2 to 2 / 3 polyethylene-vinyl acetate and thermoplastic polyurethane to 140-160°C, add paraffin wax and antioxidant in proportion, after it melts, add the remaining polyethylene-vinyl acetate and thermoplastic polyurethane , to ensure that the system temperature is ≥130°C;

[0080] b: Add polypropylene grafted maleic anhydride (PP-g-MAH) in proportion to ensure that the system temperature is ≥120°C. After it melts, add rosin pentaerythritol ester and C5 hydrogenated petroleum resin, and cool down to 90-110°C. After it melts, add an anti-aging agent, keep warm and stir for 10-30 minutes, and discharge to obtain a metal-adhesive EVA-based hot-melt adhesive.

[0081] Both step a and step b are carried ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com