Shoe insert pad

a technology for inserting pads and shoes, applied in the direction of uppers, soles, insoles, etc., can solve the problems of affecting the service life of the car, and requiring constant repair and collapse rituals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

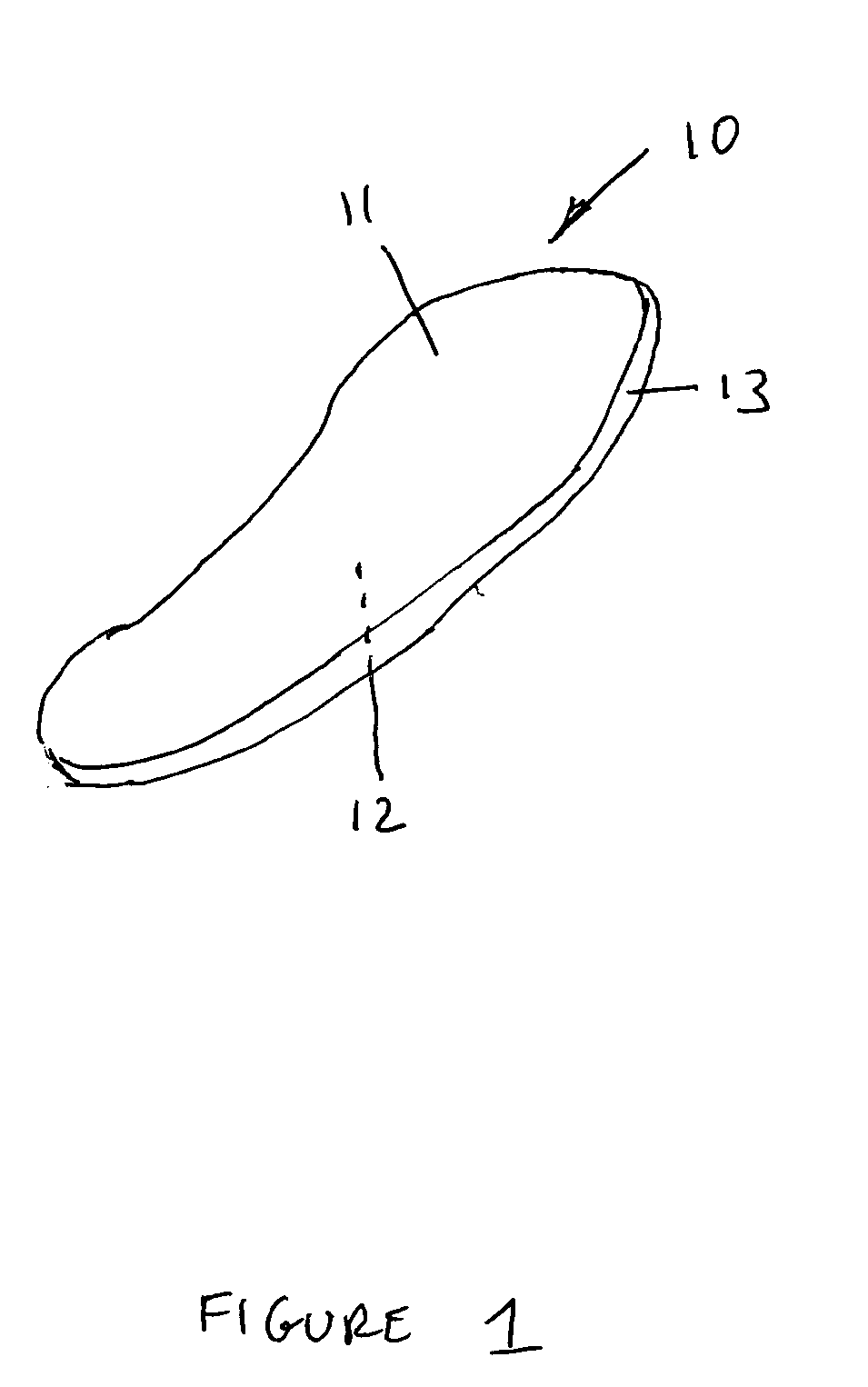

[0022] Referring now to the drawing, and in particular to FIG. 1, there is shown a shoe insert pad 10. The shoe insert pad 10 includes a first planar surface 11 and a second planar surface 12 opposite the first planar surface 11.

[0023] The first planar surface 11 and the second planar surface 12 are shaped substantially in the shape of a human foot. Additionally, the first planar surface 11 and the second planar surface 12 are defined by an edge 13. The edge 13 may be of varying thickness, but in a preferred embodiment of the present invention, the edge 13 of the shoe insert pad 10 is {fraction (3 / 16)} inches thick.

[0024] In a preferred embodiment of the present invention, the shoe insert pad 10 is formed of a rigid foam material, specifically a polyethylene vinyl acetate (EVA) material. However, other materials known to one of ordinary skill in the art may be used to form the shoe insert pad 10 without departing from the scope and spirit of the invention. The EVA material will ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com