Heat conduction composite material and preparation method thereof

A heat-conducting composite material, mass percentage technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve problems such as the decrease of impact strength and bending strength, and the decrease of mechanical properties of composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

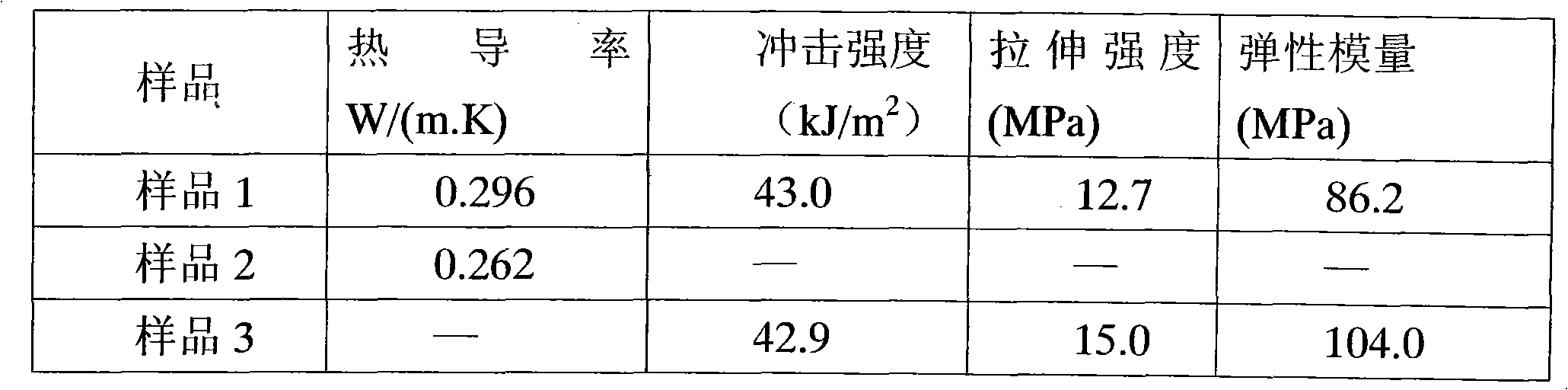

[0018] Weigh 220g of polyethylene (PE), 220g of polyethylene-vinyl acetate (EVA), add 7.5g of wetting agent, 2.5g of antioxidant and mix well in the mixer; add 50g of nano alumina to it, Stir and mix well in the mixer. The uniformly mixed materials are melt-extruded, cooled, drawn, and pelletized through a twin-screw extruder to prepare a thermally conductive composite material (sample 1).

[0019] Use PE alone as the matrix composite as a thermal conductivity control. Weigh 440 g of PE, add 7.5 g of wetting agent, and 2.5 g of antioxidant to mix well in the mixer; add 50 g of nano alumina to it, stir and mix well in the mixer. The uniformly mixed materials are melted and extruded through a twin-screw extruder, cooled, drawn, and pelletized to prepare a thermally conductive composite material (sample 2).

[0020] A blend of PE and EVA without adding nano-alumina was used as a mechanical performance control. Weigh 245g of PE, 245g of EVA, add 7.5g of wetting agent, and 2.5g of an...

Embodiment 2

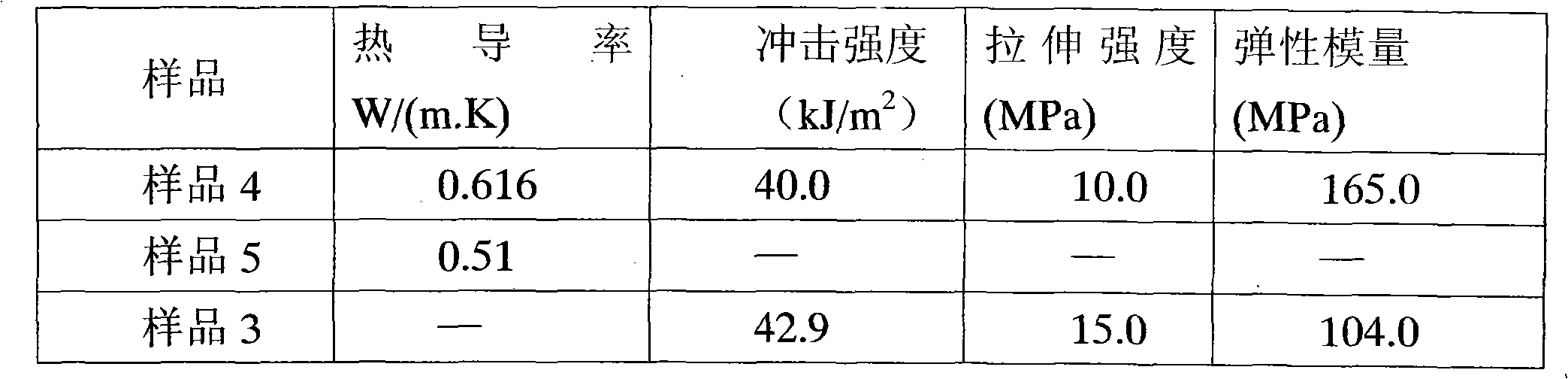

[0028] Weigh 100g polyethylene (PE), 100g polyethylene-vinyl acetate (EVA), add 7.5g wetting agent, 2.5g antioxidant and mix well in the mixer; add 290g of nano alumina to it, Stir and mix well in the mixer. The uniformly mixed materials are melted and extruded through a twin-screw extruder, cooled, drawn, and pelletized to prepare a thermally conductive composite material (sample 4).

[0029] Use PE alone as the matrix composite as a thermal conductivity control. Weigh 200 g of PE, add 7.5 g of wetting agent, and 2.5 g of antioxidant to mix well in the mixer; add 290 g of nano alumina to it, and stir and mix well in the mixer. The uniformly mixed materials are melted, extruded, cooled, drawn, and pelletized through a twin-screw extruder to prepare a thermally conductive composite material (sample 5).

[0030] Take sample 3 as a mechanical performance control.

[0031] The thermal conductivity test adopts the HC-110 thermal conductivity meter manufactured by the American EKO Compa...

Embodiment 3

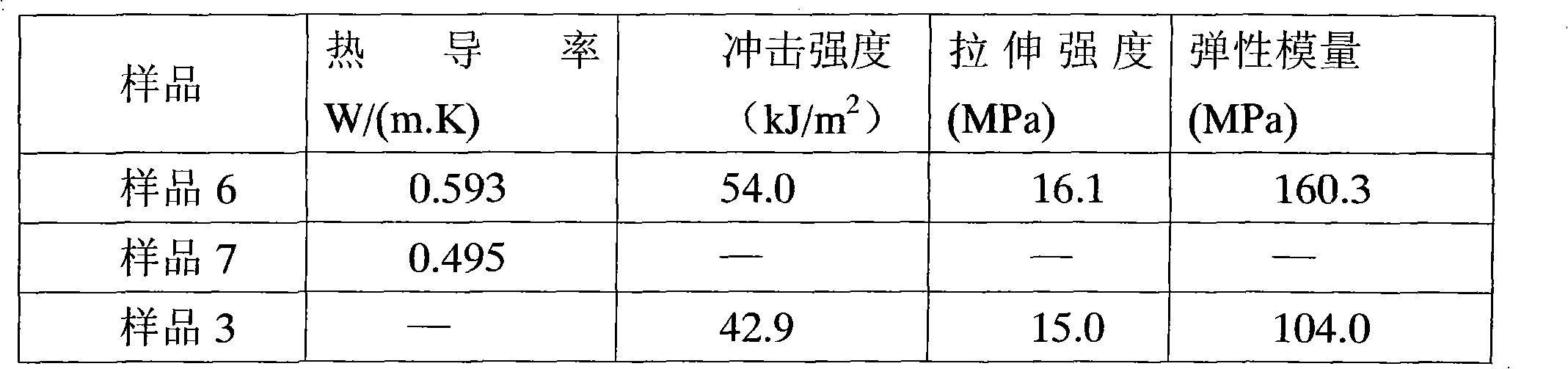

[0038] Weigh 122.5g of polyethylene (PE), 122.5g of polyethylene-vinyl acetate (EVA), add 7.5g of wetting agent, and 2.5g of antioxidant to mix well in the mixer; add 245g of nano alumina , Stir and mix well in the mixer. The uniformly mixed materials are melted, extruded, cooled, drawn, and pelletized through a twin-screw extruder to prepare a thermally conductive composite material (sample 6).

[0039] Use PE alone as the matrix composite as a thermal conductivity control. Weigh 245 g of PE, add 7.5 g of wetting agent, and 2.5 g of antioxidant to mix well in the mixer. Add 245 g of nano alumina to it, stir and mix in a mixer to be uniform. The uniformly mixed materials are melted, extruded, cooled, hauled, and pelletized through a twin-screw extruder to obtain a thermally conductive composite material (sample 7)

[0040] Take sample 3 as a mechanical performance control.

[0041] The thermal conductivity test adopts the HC-110 thermal conductivity meter manufactured by the Amer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com