Thermal insulation material and preparation method thereof

A technology of thermal insulation material and mica, applied in the field of thermal insulation, can solve the problems of high comprehensive cost, consumption, and difficulty in construction of thermal insulation layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]A thermal insulation material, composed of mica, vinyl alcohol, polyethylene vinyl acetate, polyvinyl alcohol, cement, saponite, nitrile, epoxy resin, hydroxypropyl methylcellulose, sodium dodecylbenzene sulfonate, It is made by mixing dibutyl phthalate, polyacrylamide and starch ether with water, and it is characterized in that: the weight percentages of the above-mentioned components in the insulation material are respectively, mica: 15% to 30%, vinyl alcohol: 10% to 12%, polyethylene vinyl acetate: 8% to 10%, polyvinyl alcohol: 5% to 6%, cement: 5% to 10%, soapstone: 3% to 4%, nitrile: 5% ~8%, epoxy resin: 5% ~ 8%, hydroxypropyl methylcellulose: 3% ~ 5%, sodium dodecylbenzenesulfonate: 2% ~ 5%, dibutyl phthalate : 0.8% to 1%, polyacrylamide: 0.7% to 0.9%, starch ether: 0.05% to 1%, and the rest is water. Mica is a powder with a particle size ranging from 1 micron to 0.6 mm; the mica is white cloud One or more of mother, sericite, phlogopite, biotite, lepidolite.

[...

Embodiment 2

[0046] A thermal insulation material, composed of mica, vinyl alcohol, polyethylene vinyl acetate, polyvinyl alcohol, cement, saponite, nitrile, epoxy resin, hydroxypropyl methylcellulose, sodium dodecylbenzene sulfonate, It is made by mixing dibutyl phthalate, polyacrylamide and starch ether with water, and it is characterized in that: the weight percentages of the above-mentioned components in the insulation material are respectively, mica: 15% to 30%, vinyl alcohol : 10% ~ 12%, polyethylene vinyl acetate: 8% ~ 10%, polyvinyl alcohol: 5% ~ 6%, cement: 5% ~ 10%, soapstone: 3% ~ 4%, nitrile: 5 %~8%, epoxy resin: 5%~8%, hydroxypropyl methylcellulose: 3%~5%, sodium dodecylbenzenesulfonate: 2%~5%, dibutyl phthalate Ester: 0.8% to 1%, polyacrylamide: 0.7% to 0.9%, starch ether: 0.05% to 1%, and the rest is water. Mica is a powder with a particle size ranging from 1 micron to 0.6 mm; the mica is One or more of muscovite, sericite, phlogopite, biotite and lepidolite.

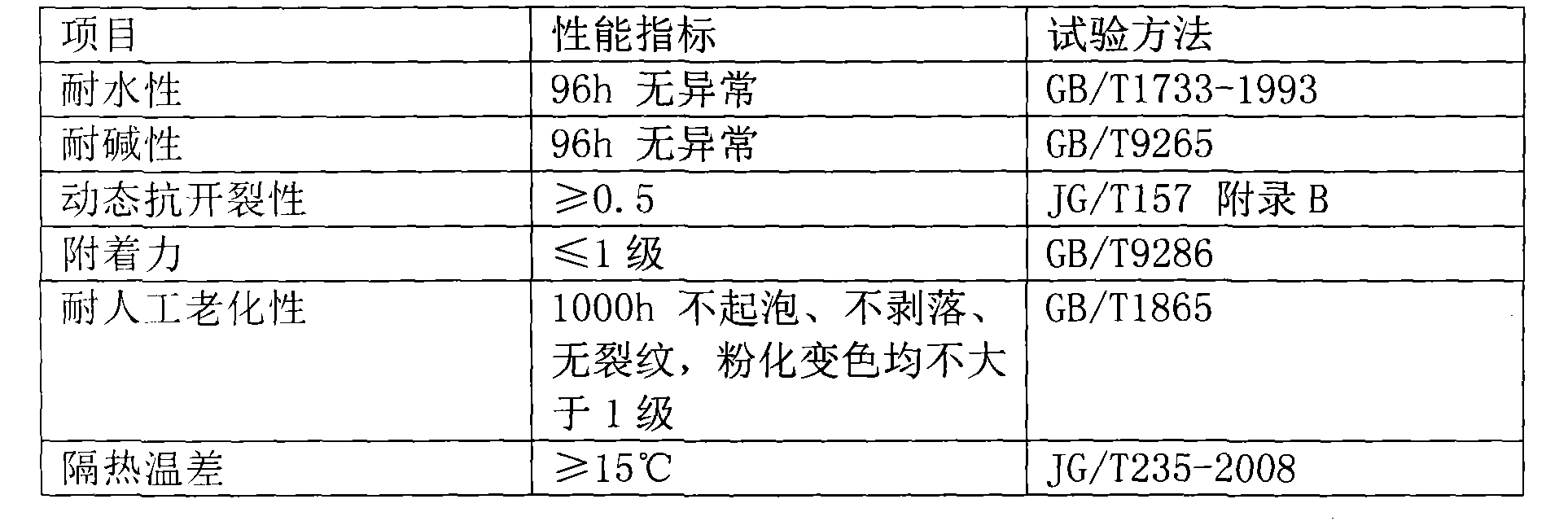

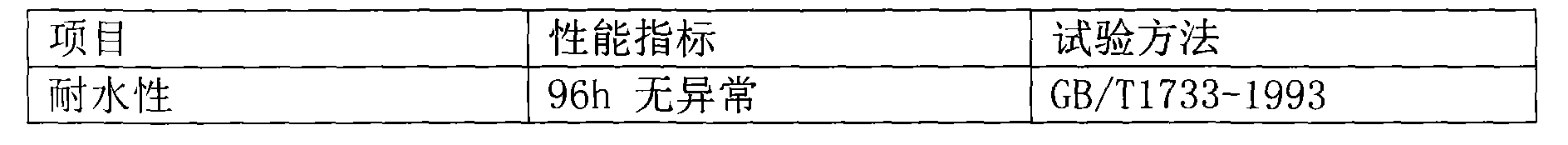

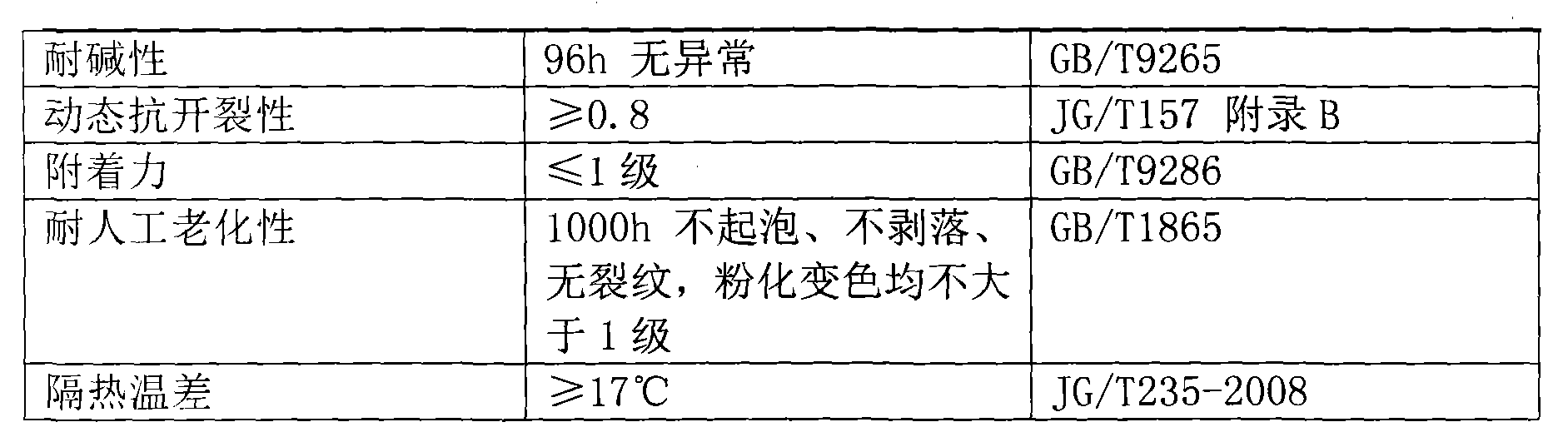

[0047] Expe...

Embodiment 3

[0055] Experimental Materials:

[0056] Mica: 15% to 30%, vinyl alcohol: 10% to 12%, polyethylene vinyl acetate: 8% to 10%, polyvinyl alcohol: 5% to 6%, cement: 5% to 10%, soapstone: 3%~4%, Nitrile: 5%~8%, Epoxy resin: 5%~8%, Hydroxypropyl methylcellulose: 3%~5%, Sodium dodecylbenzenesulfonate: 2% ~5%, dibutyl phthalate: 0.8% ~ 1%, polyacrylamide: 0.7% ~ 0.9%, starch ether: 0.05% ~ 1%, the rest is water, mica is a particle size range of 1 micron to 0.6 mm powder; the mica is one or more of muscovite, sericite, phlogopite, biotite and lepidolite.

[0057] Phlogopite with a particle size of 0.8mm: 9%, vinyl alcohol: 11%, polyethylene vinyl acetate: 10%, polyvinyl alcohol: 6%, cement: 12%, soapstone: 3.5%, nitrile: 7%, Epoxy resin: 7%, hydroxypropyl methylcellulose: 4%, sodium dodecylbenzenesulfonate: 4%, dibutyl phthalate: 0.9%, polyacrylamide: 0.8%, starch ether : 1%, gypsum: 1%, fungicide and / or defoamer: 0.1%.

[0058] Experimental program:

[0059] Add water to the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com