Composite photo voltaic hot water building integrated member and its producing process

A production process and composite light technology, applied in the field of solar energy utilization, can solve problems such as hindering the promotion of photovoltaic systems and photothermal systems, limited roof utilization, and decreased battery power generation efficiency, so as to improve indoor thermal environment, save materials, reduce The effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

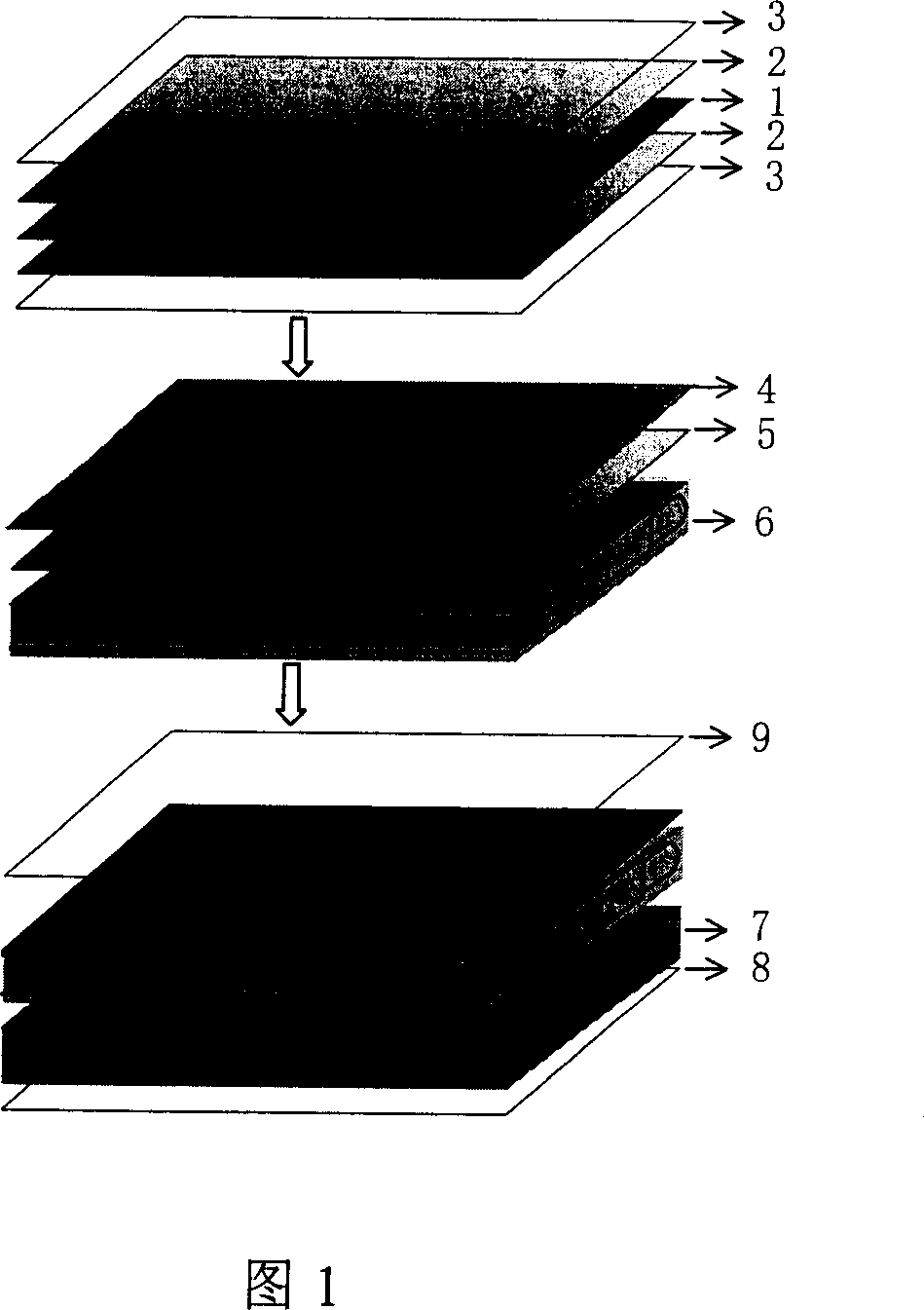

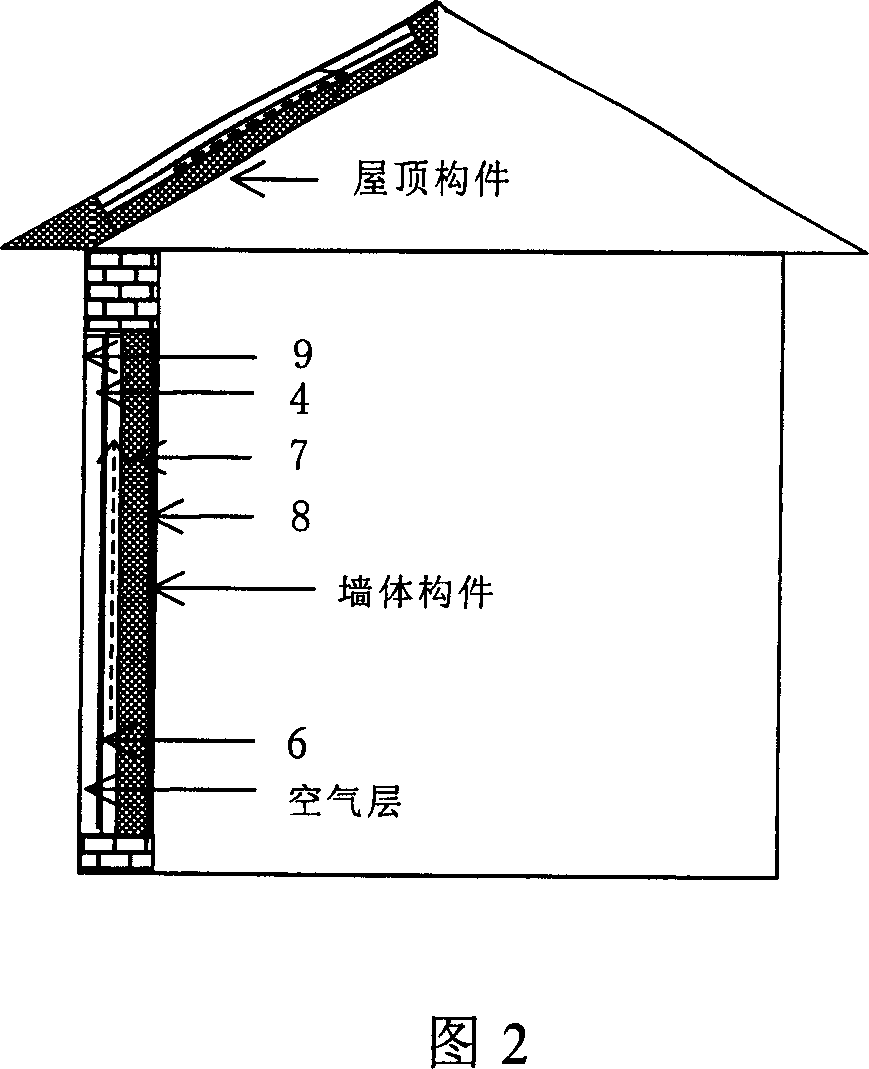

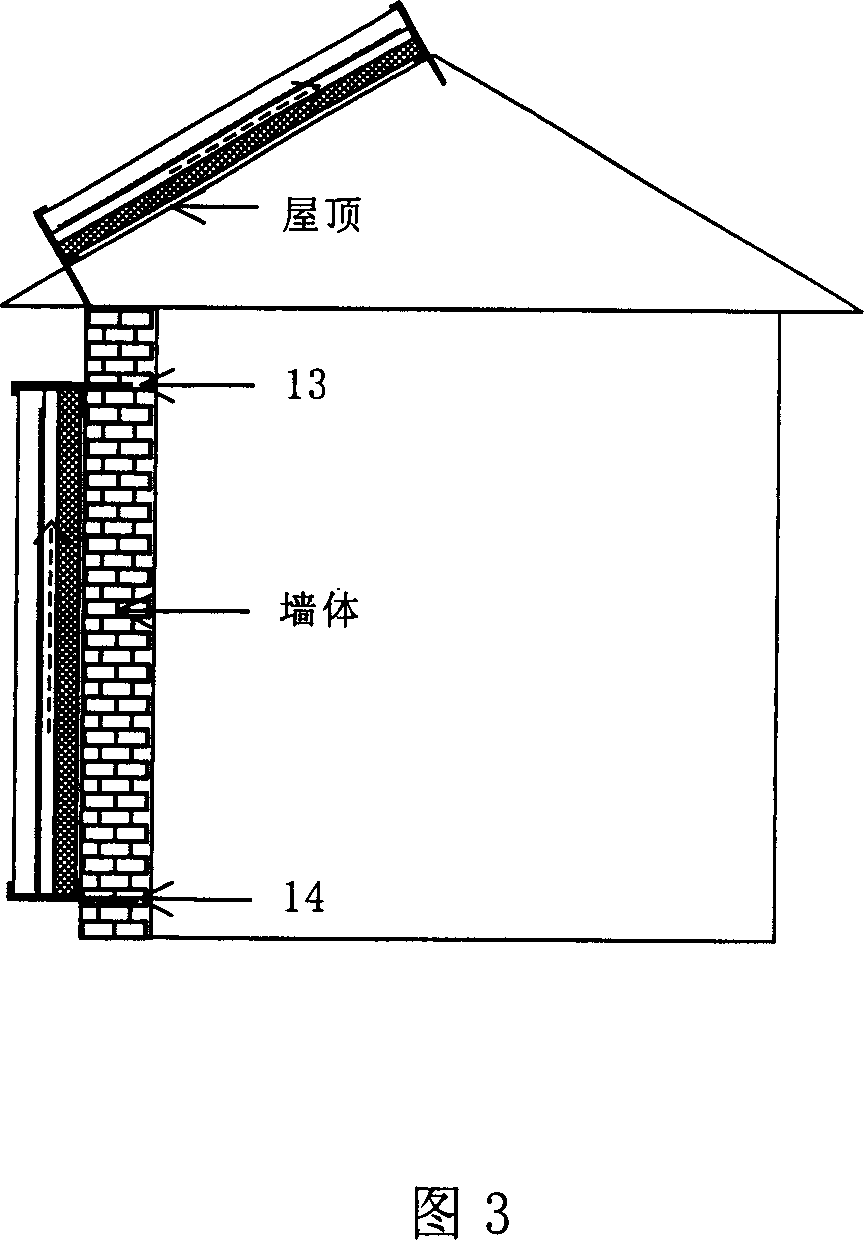

[0030] As shown in Figure 1, the composite photovoltaic hot water building integrated component structure includes: photovoltaic module 4, heat collector 6, heat insulation layer 7 and back plate 8. The photovoltaic module 4 is pasted on the heat collector 6, The back of the device 6 is respectively covered with an insulating layer 7 and a back plate 8 respectively, and the surroundings are fixed by a metal frame. A glass plate is used to cover 9 above the photovoltaic module 4, and the glass plate 9 is a high-transmittance glass plate with a transmittance> 0.9.

[0031] The back plate 7 of the present invention is a color steel plate, or a waterproof plate or a thin iron sheet, with a thickness of 0.3 to 0.6 mm; the heat insulating layer 7 is a rigid polyurethane foam, and the thickness is determined according to actual conditions, generally 25 to 150 mm; 6 is composed of a substrate and a water flow channel, the photovoltaic module 4 is attached to the substrate, and the water f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com