Back glue for books and magazines and production method thereof

A technology for self-adhesive, books and periodicals, applied in the direction of adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc. The effect of good low temperature brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

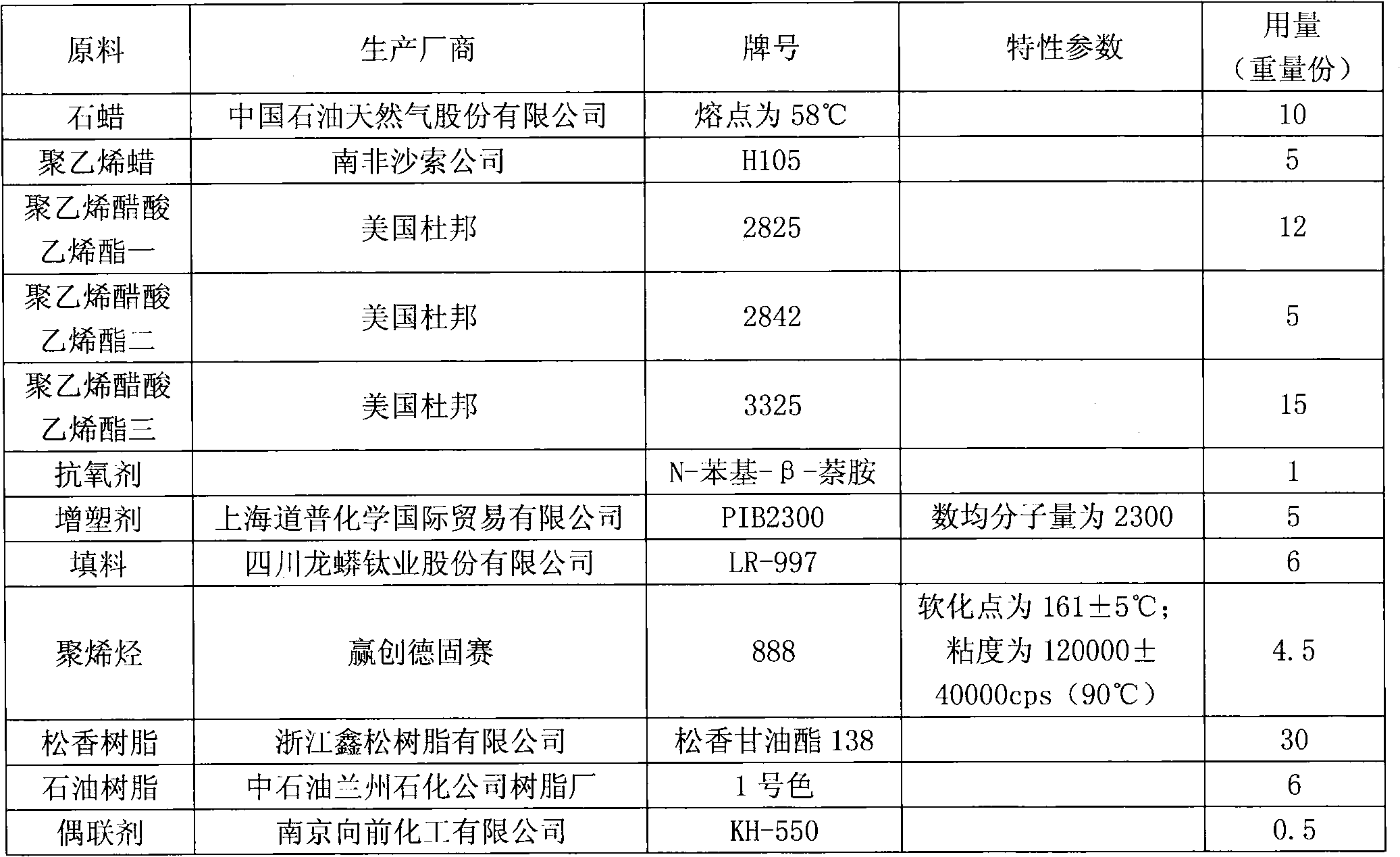

[0035] Table 1

[0036]

[0037] Step 1: Heat the paraffin to 160°C and stir until it completely melts;

[0038] Step 2: Add polyethylene vinyl acetate 1, polyethylene vinyl acetate 2, and polyethylene vinyl acetate 3 sequentially while stirring the mixture obtained in the first step, stir for 2 hours, and cool down to 135°C;

[0039] The third step: add antioxidant, filler, polyolefin, rosin resin, petroleum resin and coupling agent to the mixture obtained in the second step at the same time, after stirring evenly, vacuumize the stirring container and keep it warm for 10 minutes;

[0040] The fourth step: discharge and shape the stirred container obtained in the third step at 130°C.

Embodiment 2

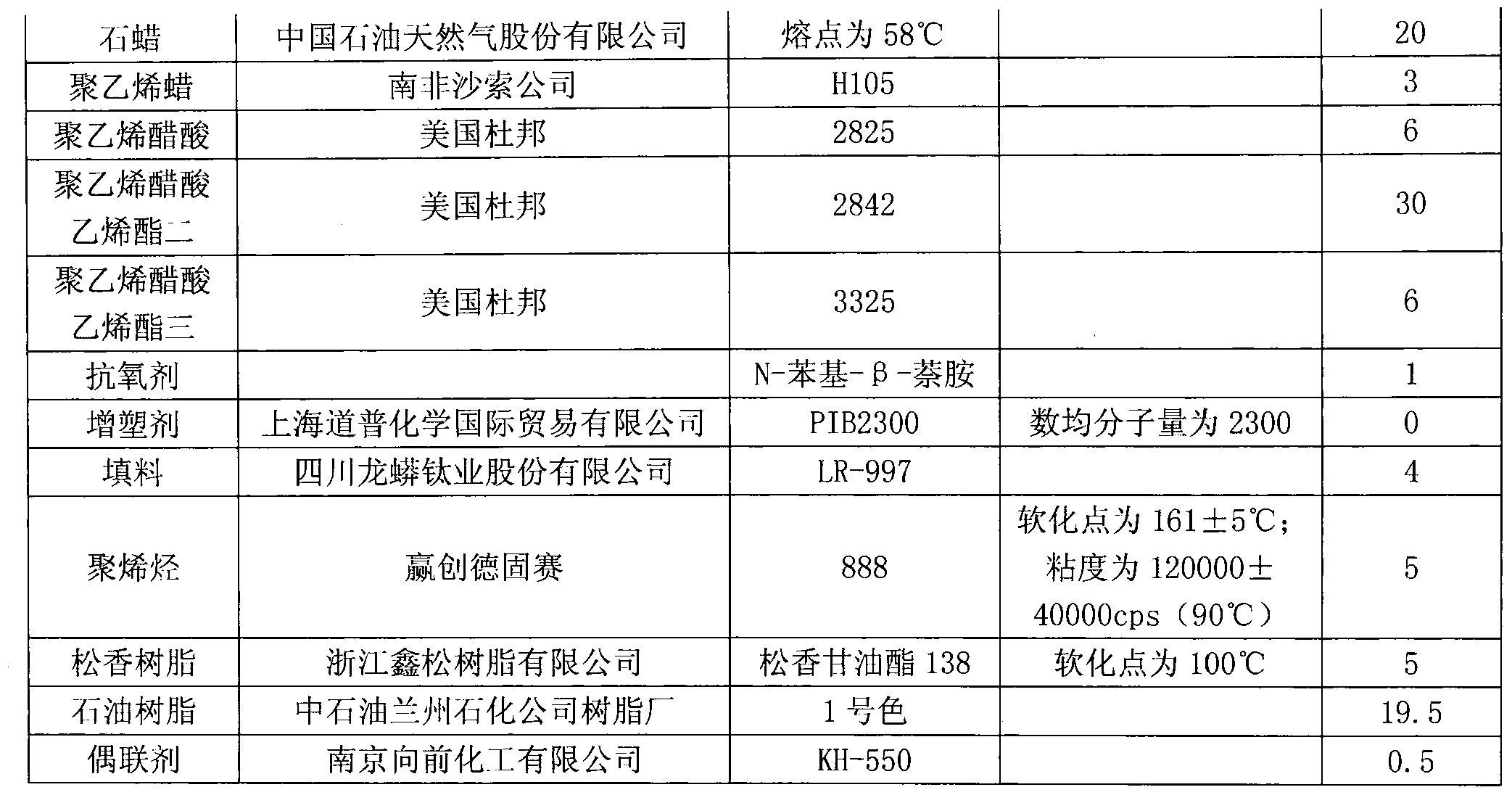

[0042] Table 2

[0043]

[0044]

[0045] Step 1: After mixing paraffin wax and polyethylene wax, heat it to 150°C and stir until it completely melts;

[0046] Step 2: Add polyethylene vinyl acetate 1, polyethylene vinyl acetate 2, and polyethylene vinyl acetate 3 sequentially while stirring the mixture obtained in the first step, stir for 2.5 hours, and cool down to 130°C;

[0047] Step 3: Add antioxidant, plasticizer, filler, polyolefin, rosin resin, petroleum resin and coupling agent to the mixture obtained in the second step. After stirring evenly, vacuumize the stirring container and keep it warm for 12 minutes ;

[0048] The fourth step: discharge and shape the stirred container obtained in the third step at 120°C.

Embodiment 3

[0050] table 3

[0051]

[0052]

[0053] Step 1: After mixing paraffin wax and polyethylene wax, heat it to 140°C and stir until it completely melts;

[0054] Step 2: Add polyethylene vinyl acetate 1, polyethylene vinyl acetate 2, and polyethylene vinyl acetate 3 sequentially while stirring the mixture obtained in the first step, stir for 3 hours, and cool down to 125°C;

[0055] Step 3: Add antioxidant, plasticizer, filler, polyolefin, rosin resin, petroleum resin and coupling agent to the mixture obtained in the second step. After stirring evenly, vacuumize the stirring container and keep it warm for 15 minutes ;

[0056] The fourth step: discharge and shape the stirred container obtained in the third step at 110°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com