Organic and inorganic mixed fingerprint-resistance coating and preparation method thereof

An anti-fingerprint, inorganic technology, applied in epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc., can solve environmental pollution and other problems, and achieve high gloss, fingerprint resistance, adhesion, and high hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

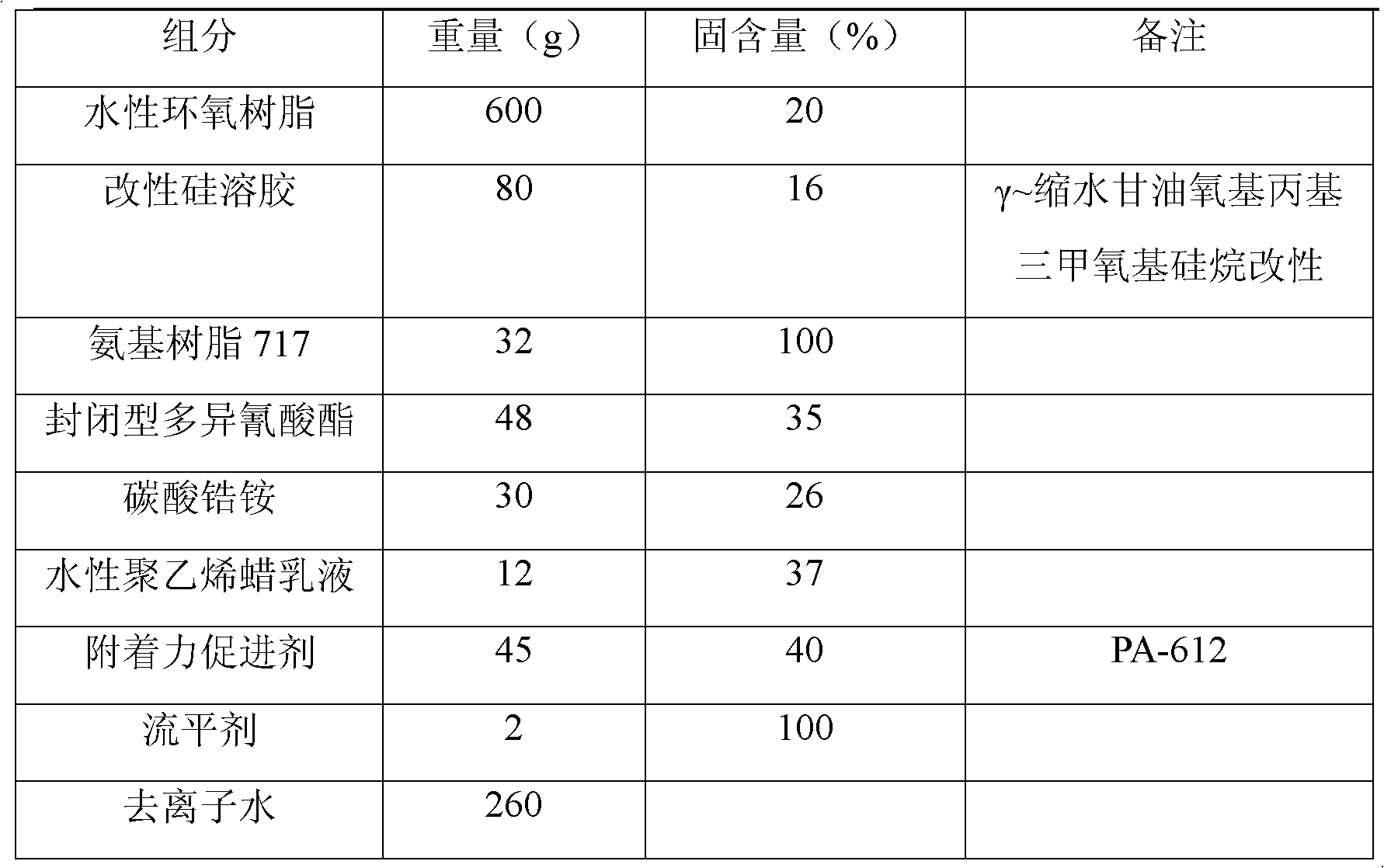

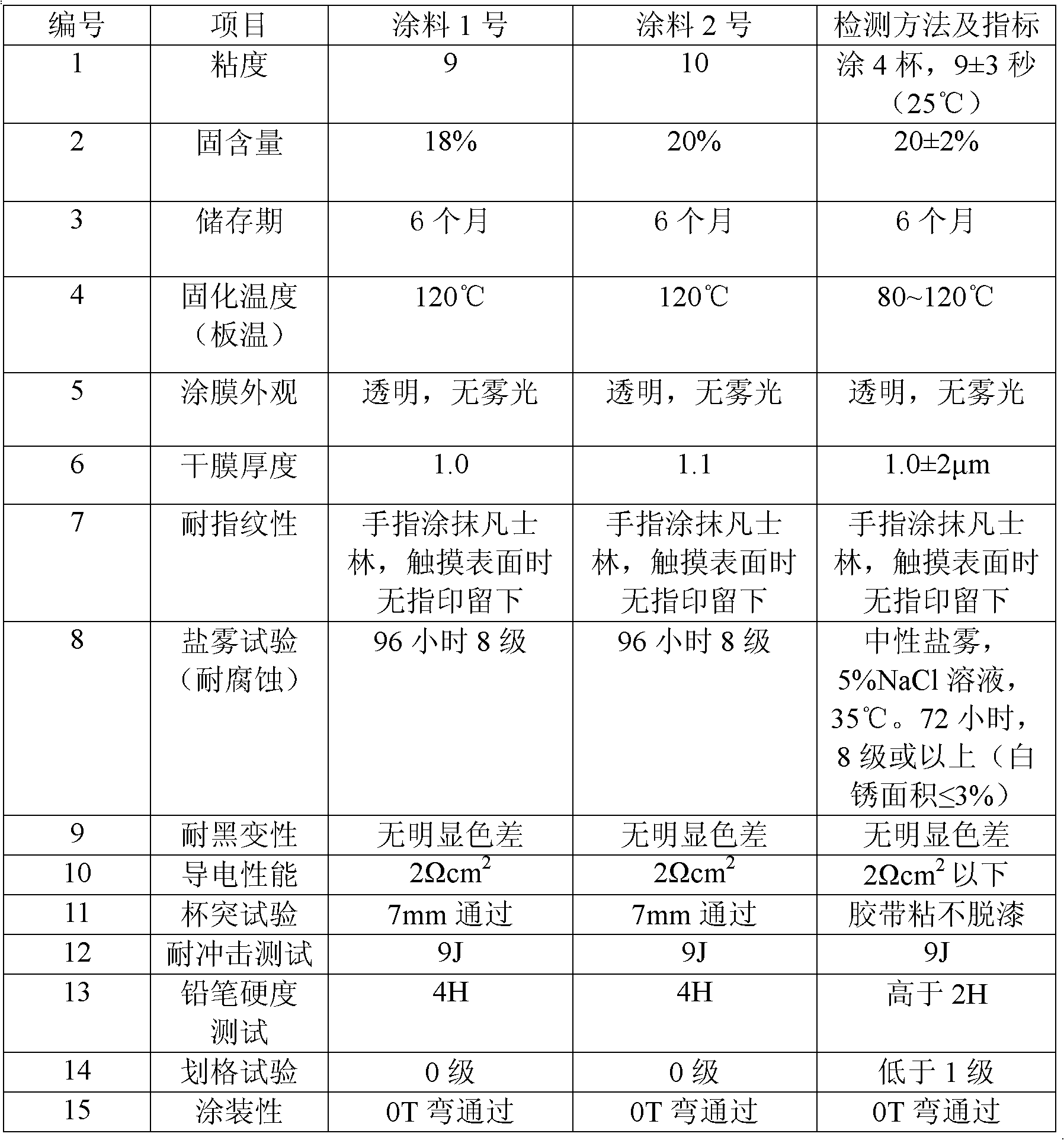

[0033] A preferred organic / inorganic hybrid anti-fingerprint coating specific proportion is as follows:

[0034] Table 1

[0035]

[0036] Put 600g of water-based epoxy resin into the reaction kettle, add 80g of modified silica sol, 30g of ammonium zirconium carbonate, 12g of water-based polyethylene wax slurry while stirring, then add 71732g of amino resin, 48g of blocked polyisocyanate and 45g of adhesion promoter , and finally put 2 g of leveling agent and 260 g of remaining deionized water into the reaction kettle, and continue to stir for 15 to 45 minutes to obtain organic / inorganic hybrid anti-fingerprint coating No. 1.

Embodiment 2

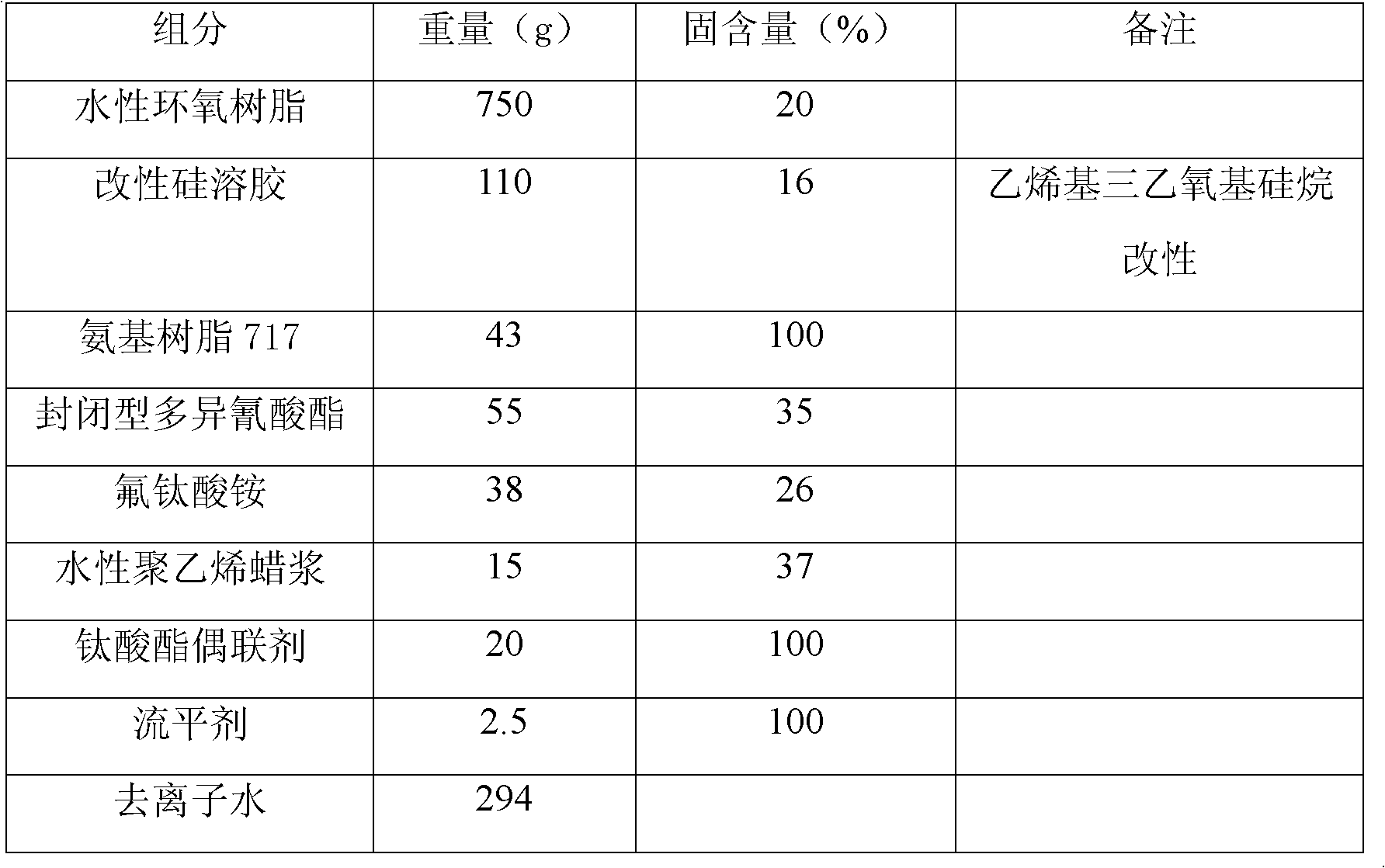

[0038] A preferred organic / inorganic hybrid anti-fingerprint coating specific proportion is as follows:

[0039] Table 2

[0040]

[0041] Put 750g of water-based epoxy resin into the reaction kettle, add 110g of modified silica sol, 38g of ammonium fluorotitanate, 15g of water-based polyethylene wax slurry while stirring, then add 71743g of amino resin, 55g of blocked polyisocyanate and titanate bismuth 20g of joint agent, and finally put 2.5g of leveling agent and the remaining 294g of deionized water into the reaction kettle, and continue stirring for 15 to 45 minutes to obtain organic / inorganic hybrid anti-fingerprint coating No. 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com