Low-volatility double-cross-linking heat-conducting phase change gel and preparation method thereof

A double-crosslinking, low-volatile technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve problems such as difficult extrusion, general thermal conductivity, and decreased filling volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

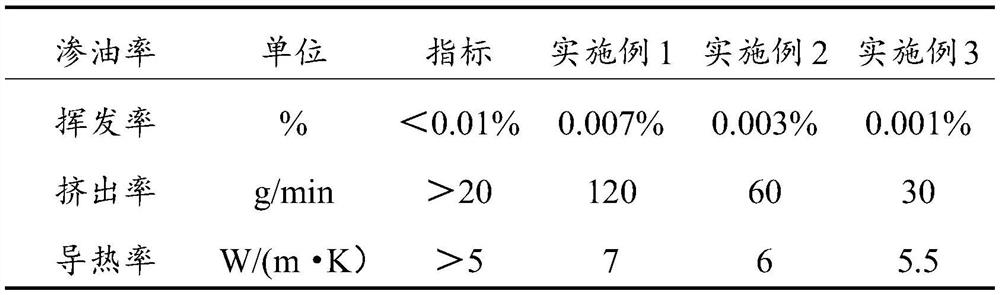

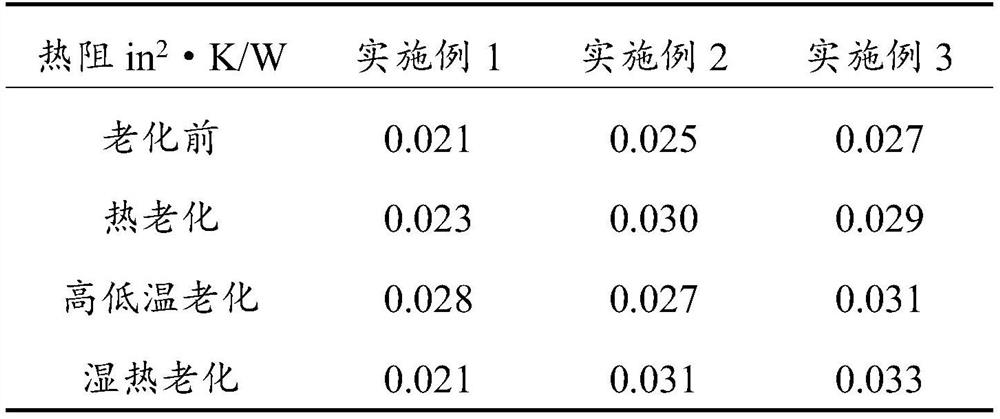

Embodiment 1

[0017] A method for preparing a low-volatility double-crosslinked thermally conductive phase-change gel, the steps are: successively add 25g of vinyl silicone rubber with a molecular weight of 10,000 and a viscosity of 100, 0.25g of dicumyl peroxide, 7g of paraffin wax at 52°C, and thiodipropylene Dilauryl acid dilauryl 0.5g, heating and stirring for 180 minutes, rotating speed of 50rpm, temperature of 150°C, vacuuming; then adding 25g of hydroxyl silicone rubber with a molecular weight of 10000 and a viscosity of 100, 0.25g of ethyl orthosilicate, and 0.01 of monobutyltin oxide g. 250g of 10μm aluminum hydroxide, the temperature is 80°C, the rotation speed is 30rpm, stirred for 120min, and vacuumized; the temperature of the material is cooled to room temperature, vacuumized, and continuously stirred for 30min.

Embodiment 2

[0019] A method for preparing a low-volatility double-crosslinked thermally conductive phase-change gel, the steps are: successively add 21 g of vinyl silicone rubber with a molecular weight of 20,000 and a viscosity of 150, 0.15 g of azoisobutyronitrile, 9 g of microcrystalline wax at 70 ° C, 2,8 - Di-tert-butyl-4-methylphenol 1g, heating and stirring for 180 minutes, rotating speed is 50rpm, temperature is 80°C, vacuumize; then add 23g of molecular weight 1000, viscosity 50 hydroxyl silicone rubber, MDI 0.5g, monobutyl oxidation Tin 0.02g, 20μm copper powder 273g, the temperature is 100°C, the rotation speed is 30rpm, stirred for 120min, and vacuumized; the temperature of the material is cooled to room temperature, vacuumized, and continuously stirred for 30min.

Embodiment 3

[0021] A method for preparing a low-volatility double-crosslinked thermally conductive phase-change gel, the steps are: successively add 30 g of methyl silicone rubber with a molecular weight of 100,000 and a viscosity of 500, 0.4 g of benzoyl peroxide, 2 g of a phase-change wax at 60°C, and butyl hydroxyl 2g of anisole, heat and stir for 180 minutes, the speed is 50rpm, the temperature is 95°C, vacuumize; then add 13g of hydroxyl silicone rubber with a molecular weight of 1000 and a viscosity of 50, 0.5g of tetraethyl orthosilicate, 0.02g of monobutyltin oxide, 1μm Alumina 200g, the temperature is 70°C, the rotation speed is 30rpm, stirred for 120min, and vacuumized; the temperature of the material is cooled to room temperature, vacuumized, and continuously stirred for 30min to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com