Low-cost recovery and regeneration method of waste scr catalyst and regenerated scr catalyst carrier

An SCR catalyst and catalyst technology, applied in the field of regenerating SCR catalyst carrier, can solve the problems of lengthy route, short service life of catalyst, complicated operation, etc., and achieve the effect of reducing drying crack rate and wear rate, reducing production cost and increasing pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

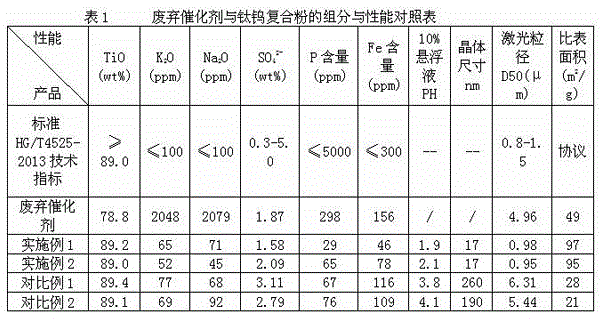

[0037] Weigh 25 kg of waste catalyst, break it into small pieces of 0.5-1cm by a plastic crusher, pass through a 50-mesh vibrating sieve, add water to wash the dust, put the washed catalyst fragments into 60 kg of dilute nitric acid with a concentration of 1M and soak 1-2 hours, after filtration, wet pulverization by pulverizer, add 50 kg of water, control the concentration of catalyst slurry at 26wt%, put it into sand mill for ultrafine pulverization, and take samples to detect that the particle diameter is 20-55nm as qualified; unqualified two Second beating;

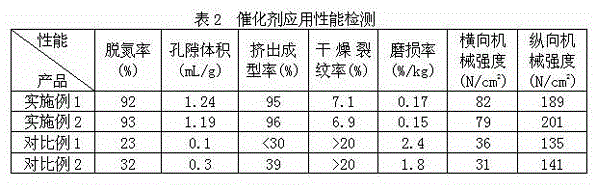

[0038] Catalyst slurry with qualified particle size and TiO 2 The metatitanic acid slurry with a content of 26wt% is mixed according to the mass ratio of 1:1, add pure water until titanium dioxide accounts for about 23wt% of the total slurry, add ammonia water to adjust the pH to 7.5, and add ammonium paratungstate and white carbon black , the addition amount meets the following requirements respectively: WO 3 The c...

Embodiment 2

[0041] Weigh 25 kg of waste catalyst, break it into small pieces of 0.5-1cm by a plastic crusher, pass through a 50-mesh vibrating sieve, add water to wash the dust, put the washed catalyst fragments into 60 kg of dilute nitric acid with a concentration of 1M and soak 1-2 hours, after filtration, wet pulverization by pulverizer, add water to adjust the concentration of catalyst slurry to control at 30wt%, put into sand mill for superfine pulverization, and take samples to detect that the particle diameter is 50-100nm as qualified; unqualified for the second time beating;

[0042] The catalyst slurry with the above-mentioned qualified particle size and TiO 2 The metatitanic acid slurry with a content of 30wt% is mixed at a mass ratio of 1:9, pure water is added until titanium dioxide accounts for about 23wt% of the total slurry, ammonia water is added to adjust the pH to 8.0, and ammonium paratungstate and white carbon black are added , the addition amount meets the following ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com