Active seal assemblies for movable windows

a technology for movable windows and seal assemblies, applied in the direction of windows, packaging, fastening means, etc., can solve the problems of trade-off in seal effectiveness, inability to change or control remotely the stiffness and cross sectional geometries of the seal assemblies, etc., and achieve the effect of increasing the seal force and reducing the seal for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

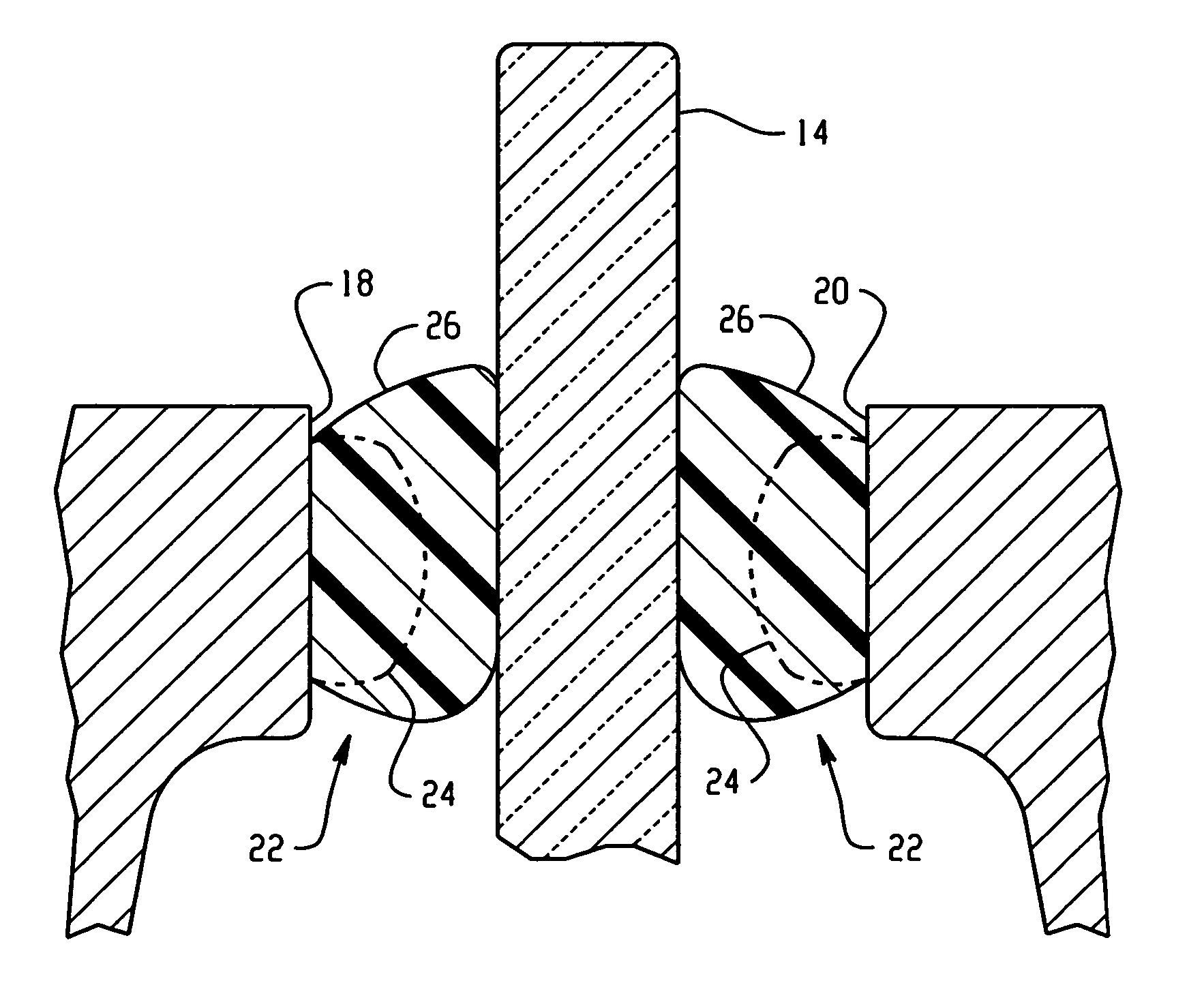

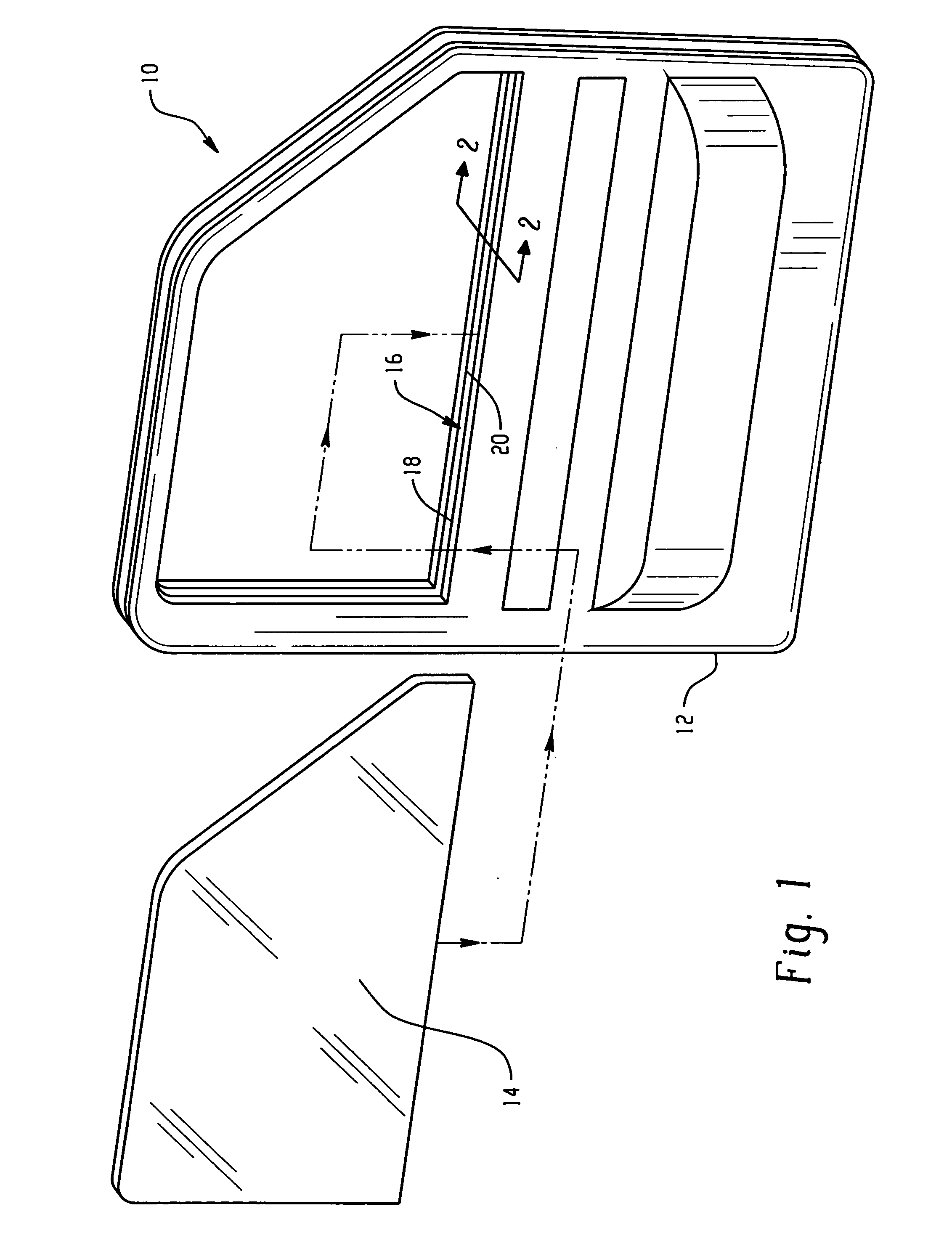

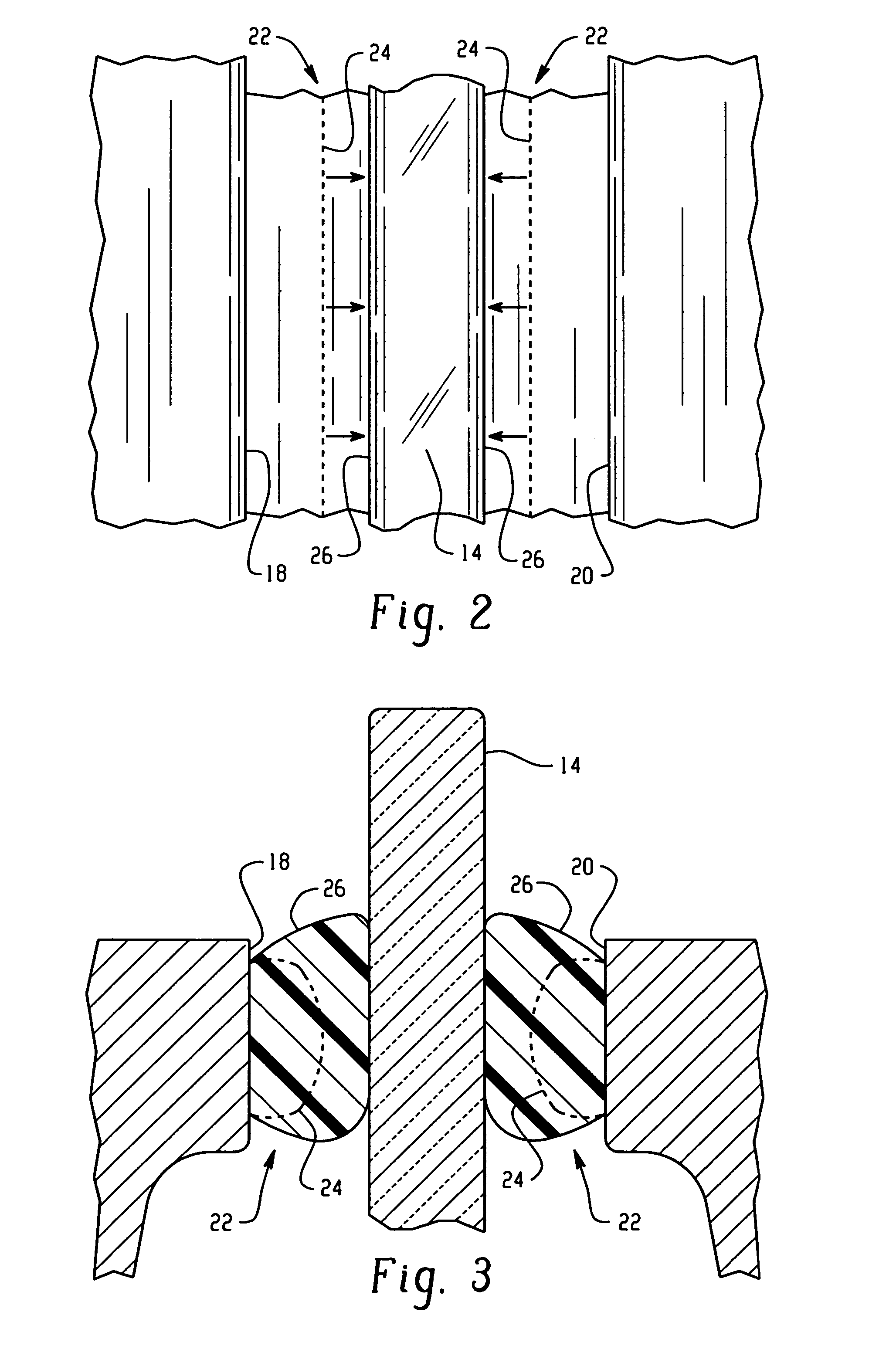

[0020] Disclosed herein are active sealing assemblies and methods of use, wherein the shape and / or modulus properties of the active seals employed in the active sealing assemblies can be remotely activated and / or controlled to selectively provide increased seal effectiveness. For automotive window applications, the active seal assemblies are programmed to provide minimal window opening and closing efforts in addition to providing increased seal effectiveness when the window is stationary. By controlling seal effectiveness by active manipulation of the seal properties, seal force can be selectively increased when the window is stationary and selectively decreased when the window is moving. As such, a smaller motor can be used to power movement of the window because the motor has less drag forces to overcome during window movement. Moreover, when the window is stationary, the seal force can be selectively maximized so as to advantageously reduce wind noise as well as prevent leaking o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com