Viewing mirror for implementing in situ optical observation in high-temperature highly pressurised liquid entironment and applications

A liquid environment, high temperature and high pressure technology, applied in the field of mirror structure, can solve sealing and other problems, and achieve high light transmittance, high temperature strength, and high temperature elasticity.

Inactive Publication Date: 2009-02-11

INST OF METAL RESEARCH - CHINESE ACAD OF SCI

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a safe and reliable sealing mirror structure that can realize in-situ optical observation under high temperature and high pressure liquid environment and its application, so as to solve the problems of high temperature and high pressure sealing in the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0048] In the embodiment, pure water is introduced into the autoclave 13, the pressure is increased to 12.7MPa by a high-pressure pump, the temperature is raised to 285°C and kept for 44 hours, and no problems are found during the whole experiment, indicating that the structure of the mirror is Can work safely and stably under this condition.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

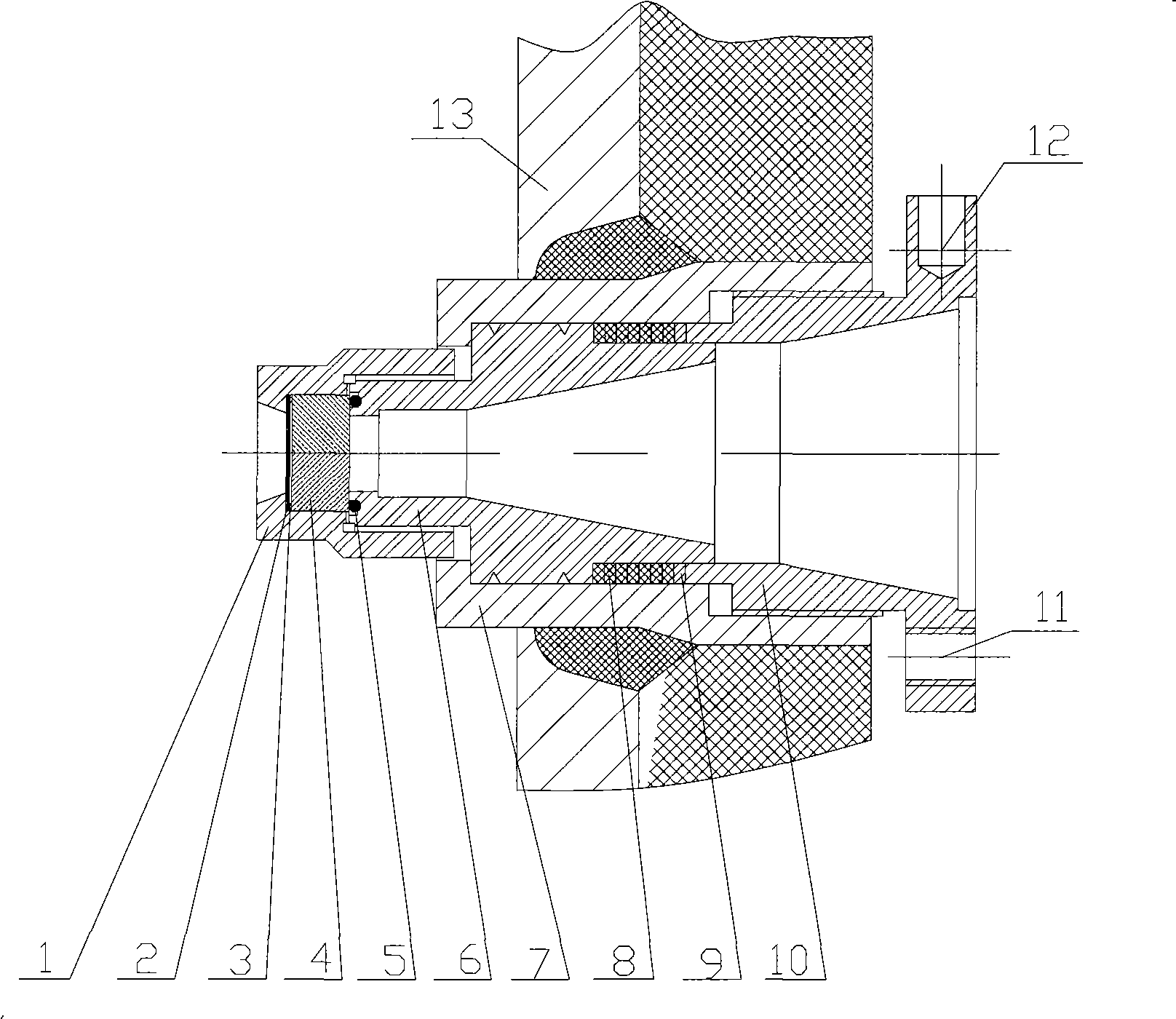

The invention relates to a lens structure, in particular to the lens structure which has safe and reliable sealing, realizes the in-situ optical observation under a high-temperature and high-pressure fluid environment (the maximum temperature and the maximum pressure can be 350 DEG C / 20MPa) as well as the application thereof, and solves the sealing and the visual (observation) problems under the high-temperature and high-pressure environment. The lens structure is assembled on an autoclave, and is composed of a pressure cap, a butterfly-shaped washer, a flat washer, a lens, an O-shaped ring, a lens barrel, a lens mount, a graphite washer, a clamping ring and a gland. When assembled, the components such as the pressure cap, the washers, the lens, and the like extend into the autoclave through the lens mount; then the gland is screwed on the lens mount until clamping the clamping ring and the washers tightly. In order to ensure that the lens barrel structure can stably work for a long time under the high-temperature fluid environment and can realize the high-quality in-situ optical observation, a single-crystal sapphire wafer with high high-temperature strength, good corrosion resistance and excellent optical performance is taken as the lens material. Besides, the invention increases the luminous flux through designing the lens barrel into a conical structure, thereby facilitating the realization of the in-situ optical observation.

Description

technical field [0001] The invention relates to a sight glass structure, in particular to a sight glass structure with safe and reliable sealing, which can realize in-situ optical observation in a high-temperature and high-pressure liquid environment, and an application thereof. Background technique [0002] In chemical, food, pharmaceutical fields and laboratories, some reactions are often carried out in a liquid environment with high temperature and high pressure. Due to the harsh reaction conditions, the monitoring of the reaction process can usually only be achieved by indirect means, and it is difficult to obtain direct and reliable information, which makes direct in-situ observation technology very necessary, and optical in-situ observation is one of them. important kind. In order to achieve optical in-situ observation in a high-temperature and high-pressure liquid environment, there must be a detection window leading into the airtight reaction vessel, and opening a d...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G02B23/00G02B7/02

Inventor 匡文军吴欣强韩恩厚

Owner INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com