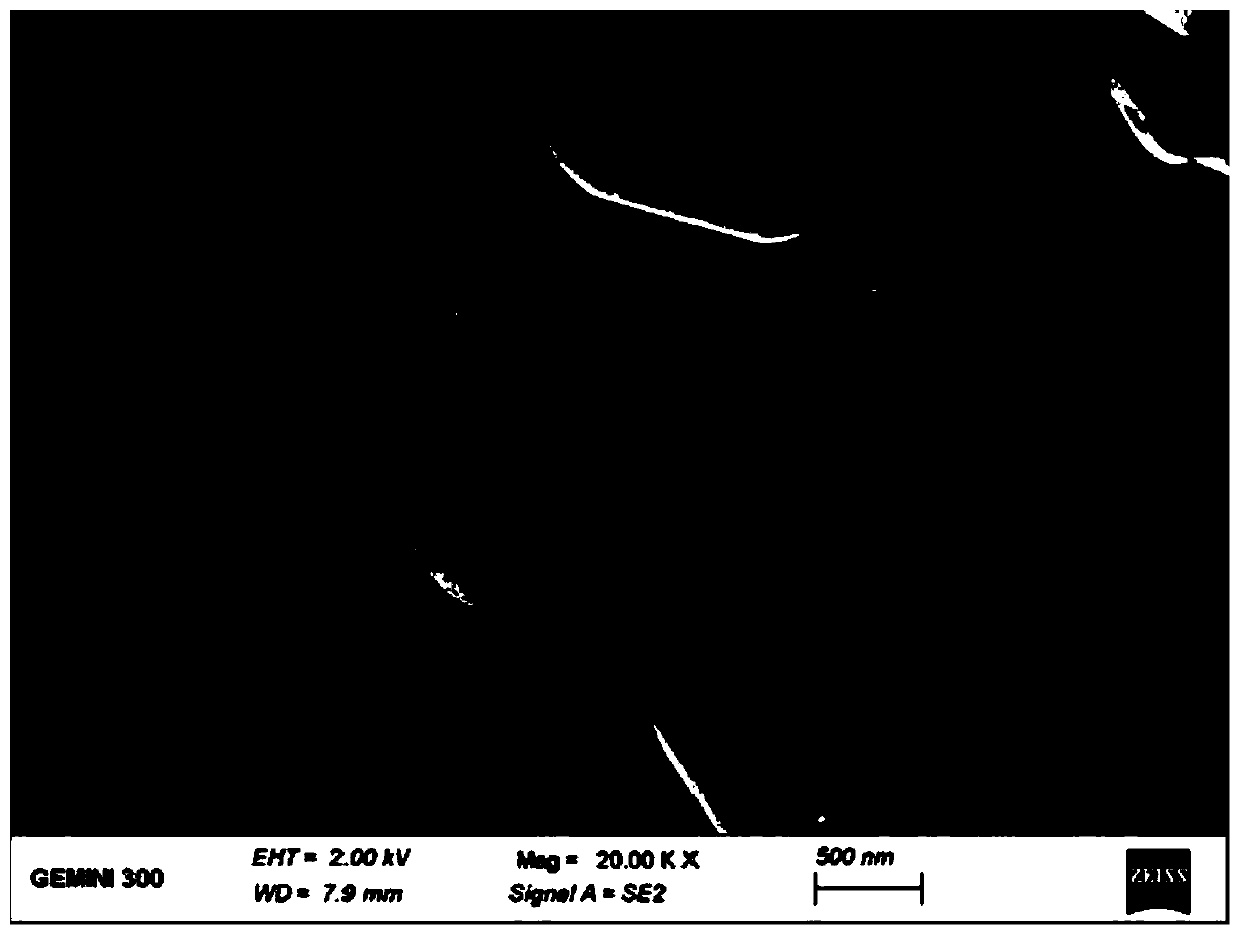

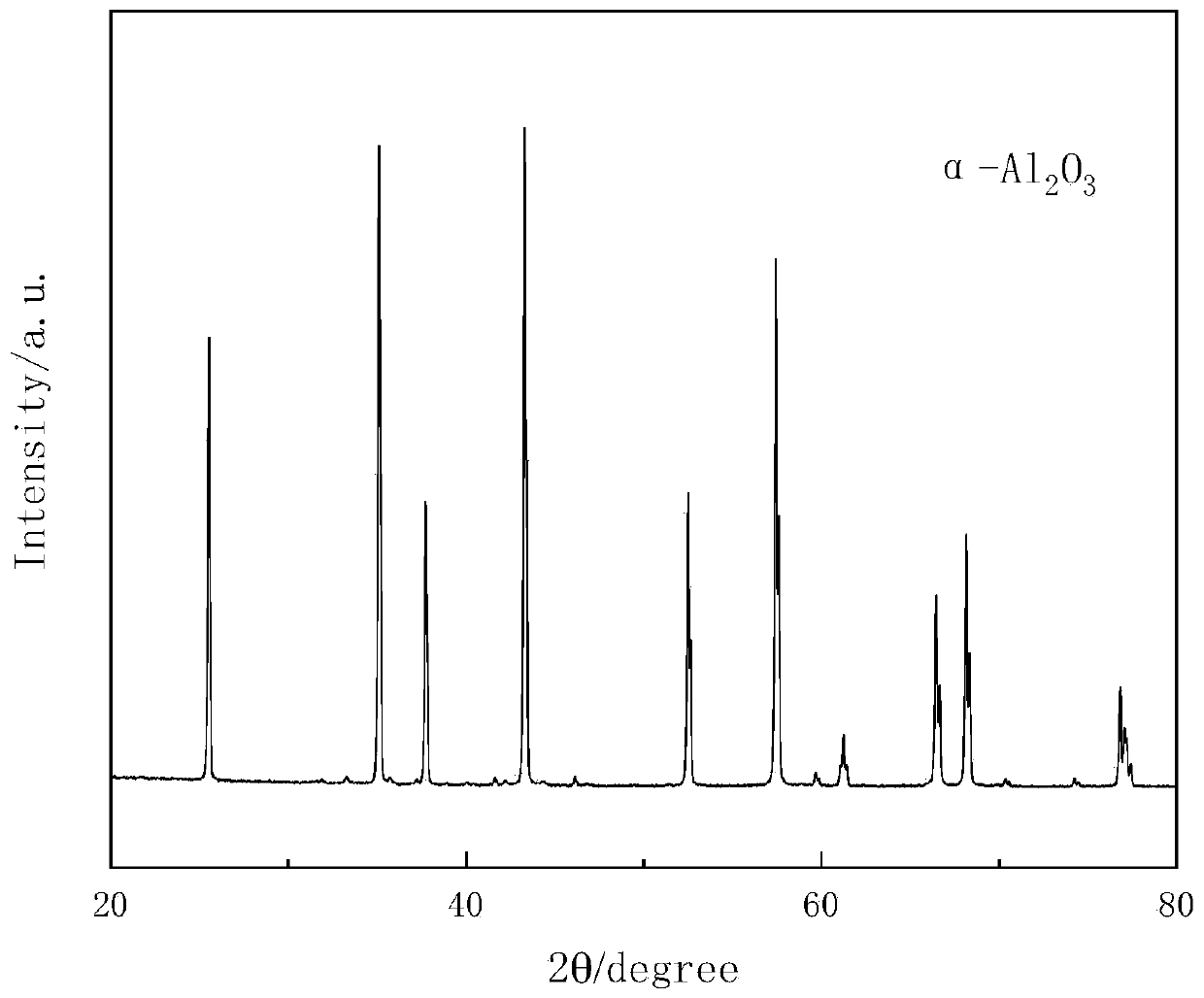

Preparation method of low-sodium orthohexagonal flaky alpha-alumina micropowder

A technology of alumina micropowder and flaky alumina, applied in chemical instruments and methods, inorganic chemistry, aluminum compounds, etc., can solve the problems of difficult control of particle size and shape, complicated production process, high production cost, etc., and achieve crystal form Well-developed, high-purity, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A low-sodium regular hexagonal flake α-Al 2 o 3 The preparation method of micropowder, comprises the steps:

[0033] (1) Mix and stir industrial aluminum hydroxide, dispersant and deionized water to form an aluminum hydroxide slurry with a solid content of 10 to 30 wt%, and grind it in a sand mill. The grinding medium is zirconia balls, and the The diameter is 1-5 μm, and the grinding time is 0.5-6 hours to obtain a refined alumina precursor slurry;

[0034] (2) Stir the alumina precursor slurry prepared in step (1) in a water bath at 70-100°C for 10-60 minutes, and add a sodium removing agent to adjust the pH value of the slurry to 4-7 while stirring, and obtain non- Basic alumina precursor slurry;

[0035] (3) The alumina precursor slurry prepared in step (2) is subjected to solid-liquid separation with a high-speed centrifuge to obtain a solid alumina precursor. The centrifugal speed is 2000-10000 rpm, and the centrifugal time is 10-60 minutes;

[0036] (4) The ...

Embodiment 1

[0042] (1) Weigh 6 parts of aluminum hydroxide powder (the initial particle size of the powder is 100 μm, and the content of sodium oxide is 0.35 wt%), 0.1 part of polyacrylamide, and 34 parts of deionized water, and make a hydrogen concentration of 15 wt%. The alumina slurry is then put into a sand mill for grinding to obtain a refined alumina precursor. The grinding medium is zirconia ball, the diameter of the ball is 2μm, and the grinding time is 2h;

[0043] (2) Stir the alumina precursor slurry prepared in step (1) in a water bath at 80°C for 30 minutes, add hydrochloric acid to adjust the pH of the slurry to 4 while stirring, and obtain a non-alkaline alumina precursor slurry material;

[0044] (3) The alumina precursor slurry prepared in step (2) is subjected to solid-liquid separation in a high-speed centrifuge to obtain a solid alumina precursor. The centrifugal speed is 5000 rpm, and the centrifugal time is 30min;

[0045] (4) The solid alumina precursor prepared ...

Embodiment 2

[0052] (1) Weigh 7 parts of aluminum hydroxide powder (the initial particle size of the powder is 80 μm, and the content of sodium oxide is 0.30 wt%), 0.21 parts of triethanolamine, and 33 parts of deionized water, and make a hydrogen concentration of 17.5 wt%. The alumina slurry is then put into a sand mill for grinding to obtain a refined alumina precursor. The grinding medium is zirconia balls, the diameter of the zirconia balls is 1 μm, and the grinding time is 3 hours;

[0053] (2) Stir the alumina precursor slurry prepared in step (1) in a 90°C water bath for 30 minutes, add nitric acid to adjust the pH of the slurry to 5 while stirring, and obtain a non-alkaline alumina precursor slurry material;

[0054] (3) The alumina precursor slurry prepared in step (2) is subjected to solid-liquid separation in a high-speed centrifuge to obtain a solid alumina precursor. The centrifugal speed is 6000 rpm, and the centrifugal time is 30 minutes;

[0055] (4) The solid-state alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com