Modified 3D printing material and preparation method thereof

A 3D printing and modification technology, which is applied in the field of preparation of modified 3D printing materials, can solve the problems affecting the dimensional stability of parts and high water absorption, and achieve good environmental and economic benefits, high flexural modulus, Effects from a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

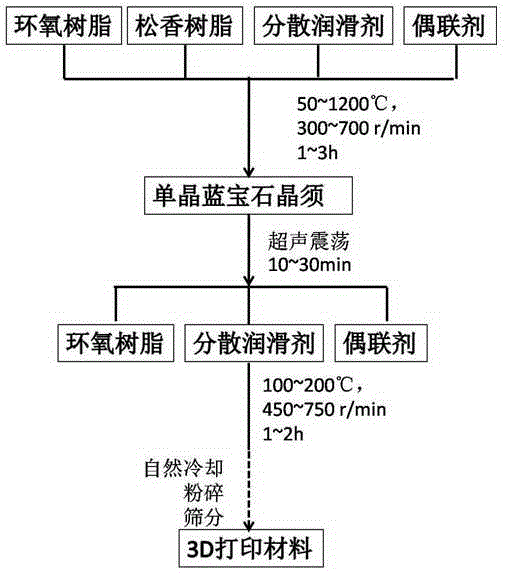

Embodiment 1

[0041] (1) Put 30 parts by weight of water glycerylamine epoxy resin, 50 parts by weight of rosin resin, 1 part by weight of polyethylene wax, and 5 parts by weight of zirconium coupling agent into the batching tank, at 80°C at 300r / min Stir for 1h.

[0042] (2) Add 30 parts by weight of single crystal sapphire whiskers to the above molten mixed liquid and vibrate for 10 minutes under ultrasonic.

[0043] (3) Add 50 parts by weight of polyamide, 0.1 part by weight of polydimethylsiloxane, and 0.2 parts by weight of castor oil to the above mixture at 100°C, and continue stirring at 450 r / min for 2 hours.

[0044] (4) After natural cooling, crushing and sieving, the modified 3D printing material can be obtained.

Embodiment 2

[0046] (1) Put 40 parts by weight of water glycerylamine epoxy resin, 40 parts by weight of rosin resin, 3 parts by weight of bis-fatty acid amide, and 7 parts by weight of zirconium coupling agent into the batching tank. Stir for 2h.

[0047] (2) Add 40 parts by weight of single crystal sapphire whiskers to the above molten mixed liquid and vibrate for 20 minutes under ultrasonic.

[0048] (3) Add 60 parts by weight of polyamide, 1 part by weight of polydimethylsiloxane, and 2 parts by weight of castor oil to the above mixture at 150°C, and continue stirring at 600 r / min for 2 hours.

[0049] (4) After natural cooling, crushing and sieving, the modified 3D printing material can be obtained.

Embodiment 3

[0051] (1) Put 50 parts by weight of water glycerylamine epoxy resin, 40 parts by weight of rosin resin, 5 parts by weight of butyl cellulose, and 8 parts by weight of zirconium coupling agent into the batching tank, and stir at 450r / min at 70°C 1h.

[0052] (2) Add 30 parts by weight of single crystal sapphire whiskers to the above molten mixed liquid and vibrate for 25 minutes under ultrasonic.

[0053] (3) Add 60 parts by weight of polyamide, 3 parts by weight of polydimethylsiloxane, and 5 parts by weight of castor oil to the above mixture at 175°C, and continue stirring at 650 r / min for 2 hours.

[0054] (4) After natural cooling, crushing and sieving, the modified 3D printing material can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com