Magnetic rheologic polishing head in electromagnetic mode

A magnetorheological polishing and electromagnetic technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inflexible processing parameters and difficult control of polishing removal volume, and achieve the effect of improving polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

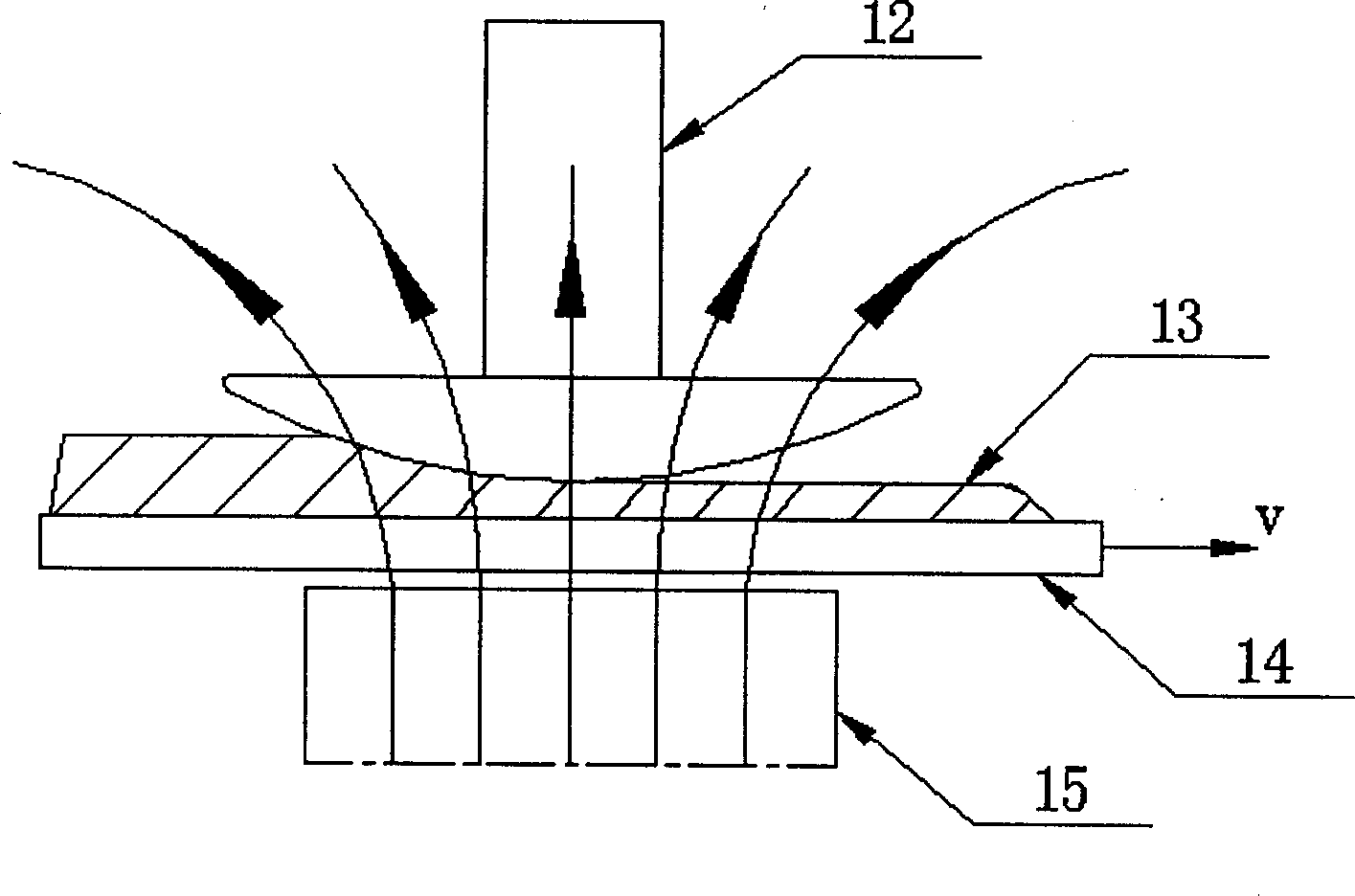

[0016] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

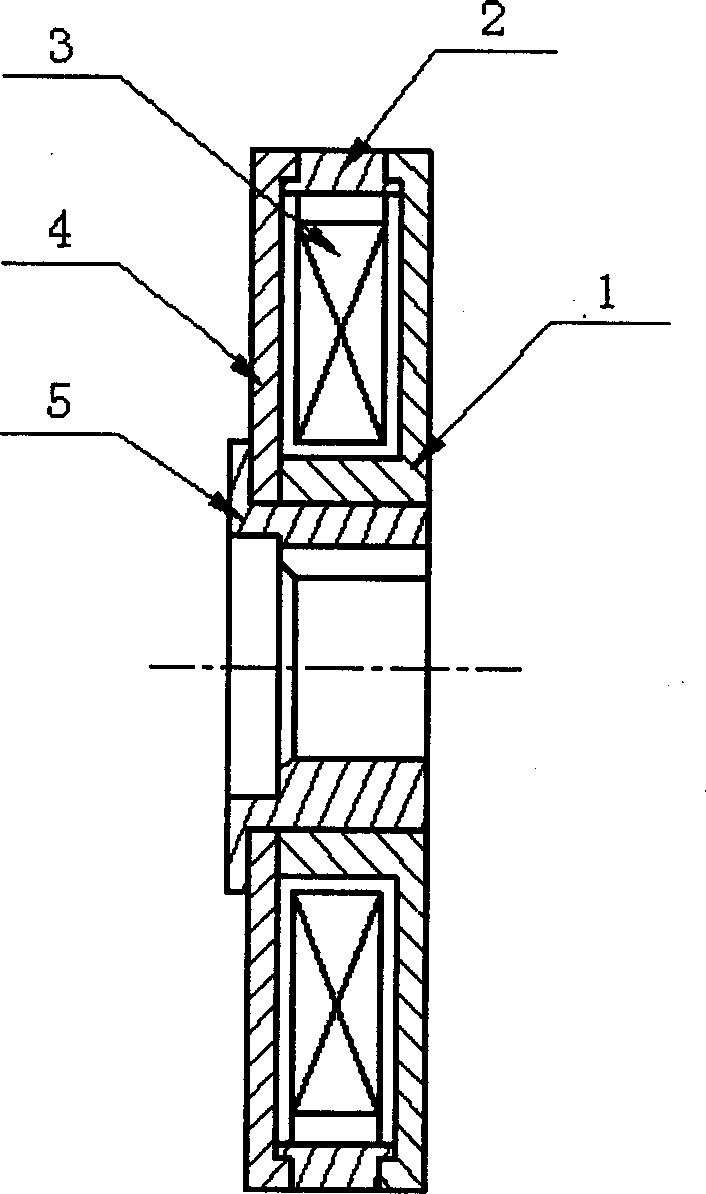

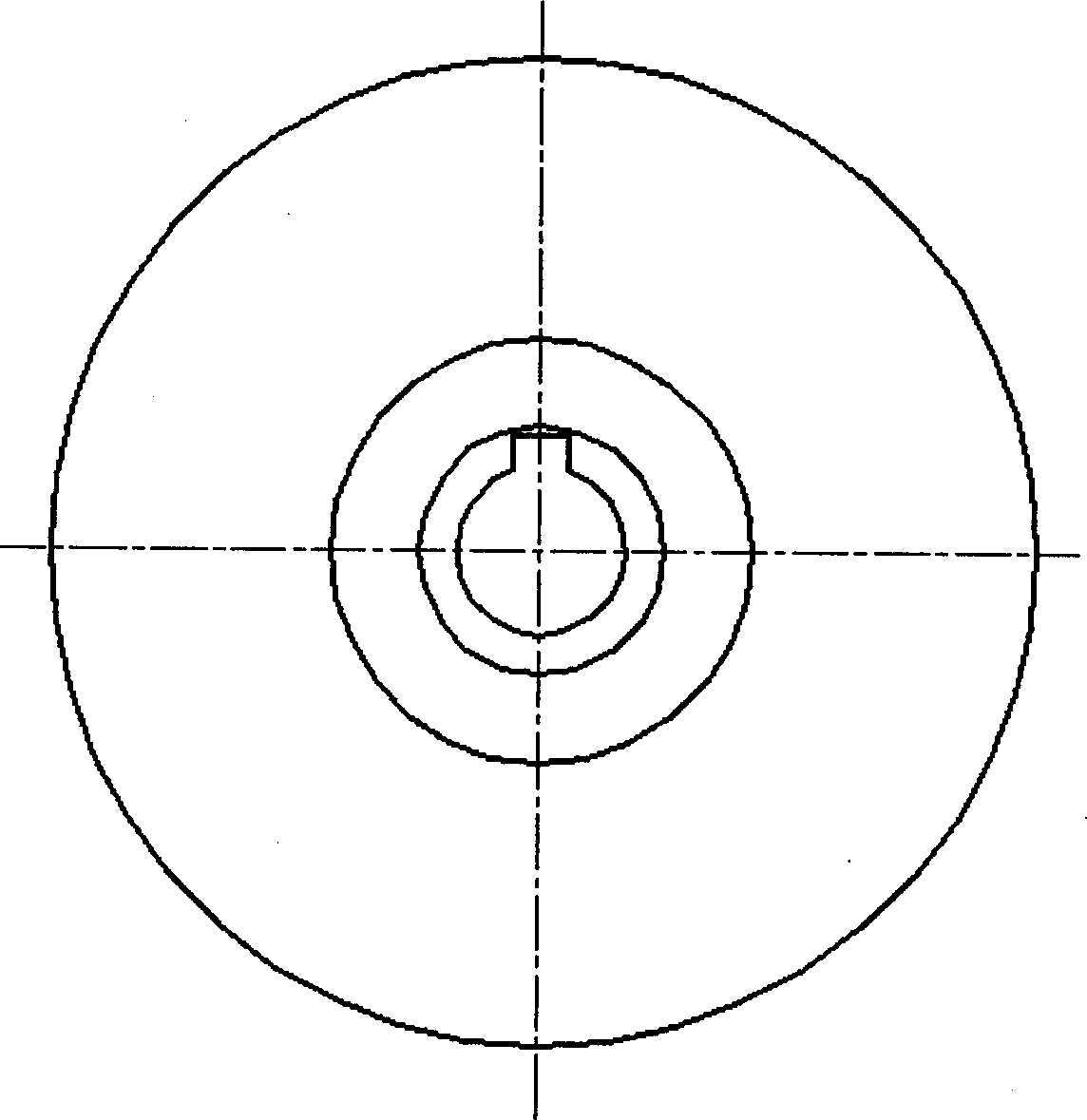

[0017] figure 2 It shows the design structure of the polishing head. It can be seen from the figure that it includes an electromagnetic wheel frame 1, a magnetic isolation ring 2, an electromagnetic coil 3, a guide disk 4 and a wheel core 5. It is characterized in that: the polishing head is disc-shaped , There are steps on both sides of the magnetic isolation ring 2, which are installed on the outer edge of the electromagnetic wheel frame 1 and the guide disk 4 through an interference fit. The magnetic isolation ring 2 plays a role of structural support and also plays a role of sealing protection for the coil; The electromagnetic wheel frame 1 and the guide disk 4 are installed together with the wheel core 5 through interference fit; The required magnetic conduction circuit is formed with the guide disk 4; the wheel core 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com