Construction variable rotary magnetic current flowing deforming brake

A magneto-rheological fluid and rotary technology, which is applied in the direction of liquid resistance brakes, brake types, mechanical equipment, etc., can solve the problems of brake working torque reduction, magnetorheological efficiency reduction, and brake structure invariance, etc., to increase damping Torque, improved magnetorheological efficiency, high economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

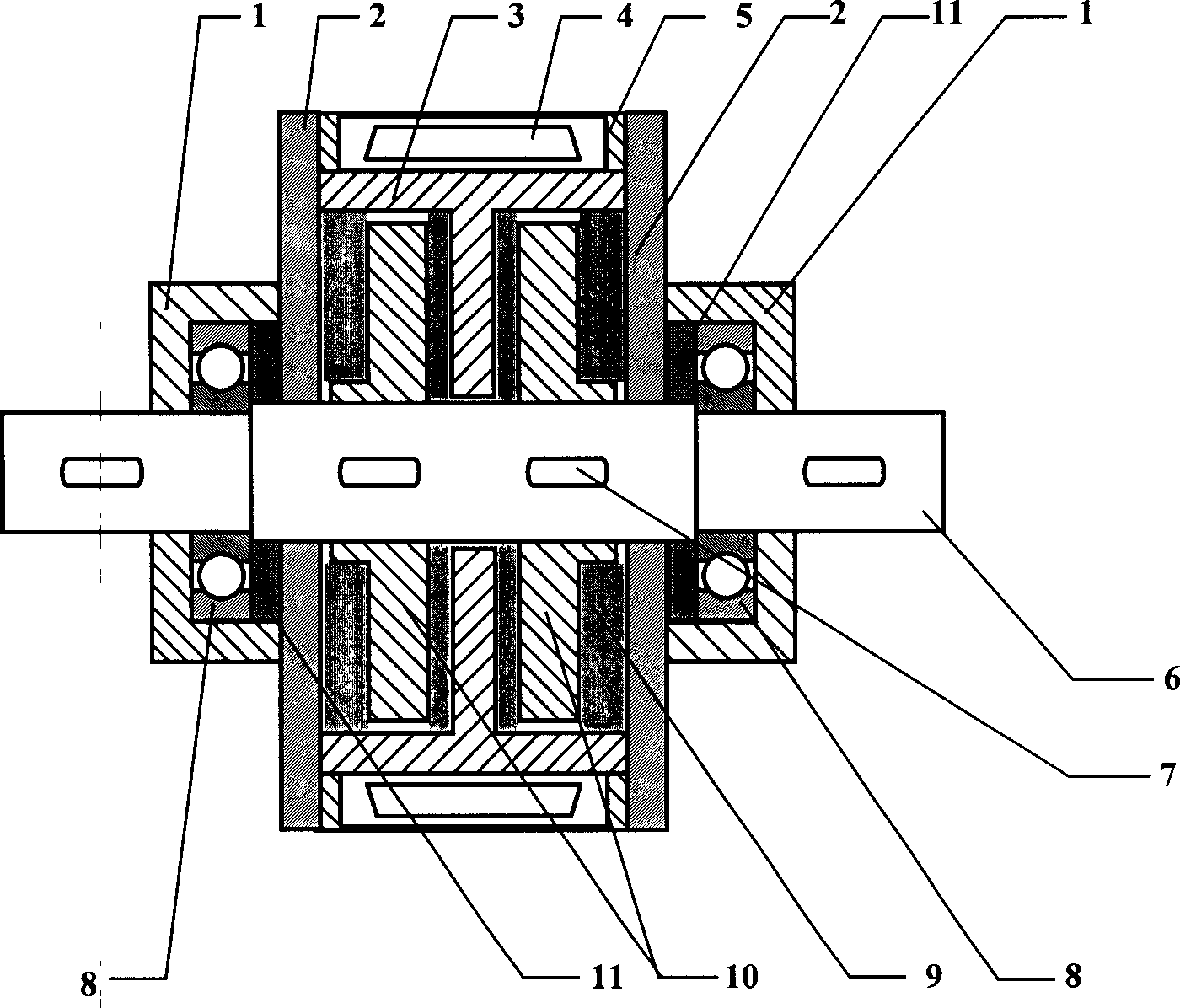

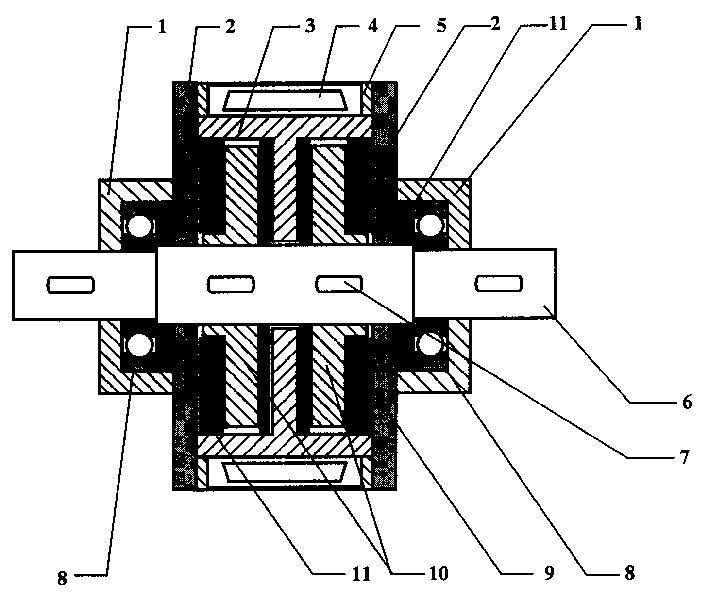

[0014] Such as figure 1 As shown, the present invention mainly includes: a bearing end cover 1, a sealing cover 2, a magnetically conductive inner cylinder 3, an electromagnetic coil 4, a magnetically conductive outer cylinder 5, a rotating shaft 6, a positioning key 7, a bearing 8, a magnetorheological fluid 9, and a turntable 10. Sealing material 11. Both the magnetically permeable inner cylinder 3 and the magnetically permeable outer cylinder 5 are cylinders made of magnetically permeable materials, wherein the magnetically permeable inner cylinder 3 is provided with a disc-shaped separation structure, and the center of the structure is provided with a shaft for the rotation of the rotating shaft 6. round hole.

[0015] After the rotating shaft 6 passes through the magnetic conduction inner cylinder 3, it is connected with the two ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com