A rotary adaptive magnetorheological fluid shock absorber

A magnetorheological fluid, self-adaptive technology, applied in the direction of shock absorber, spring/shock absorber functional characteristics, shock absorber, etc. Controllable, simple-to-build effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In a typical implementation of the present application, a rotary adaptive magnetorheological fluid shock absorber has only one layer, which includes a cylinder, which is divided into a vibration excitation layer and a magnetorheological damping layer; A full-length fixed shaft is installed inside the cylinder, and a rotating shaft is set outside the fixed shaft. The bottom end of the rotating shaft is extended to form a chassis, and a universal ball joint is set at the bottom of the chassis, which is placed in the magnetorheological fluid storage chamber. A circle of universal spherical hinges is respectively arranged on the inner side of the upper and lower ends of the rotating shaft, and the fan blade and the rotating disc are fixed on the rotating shaft.

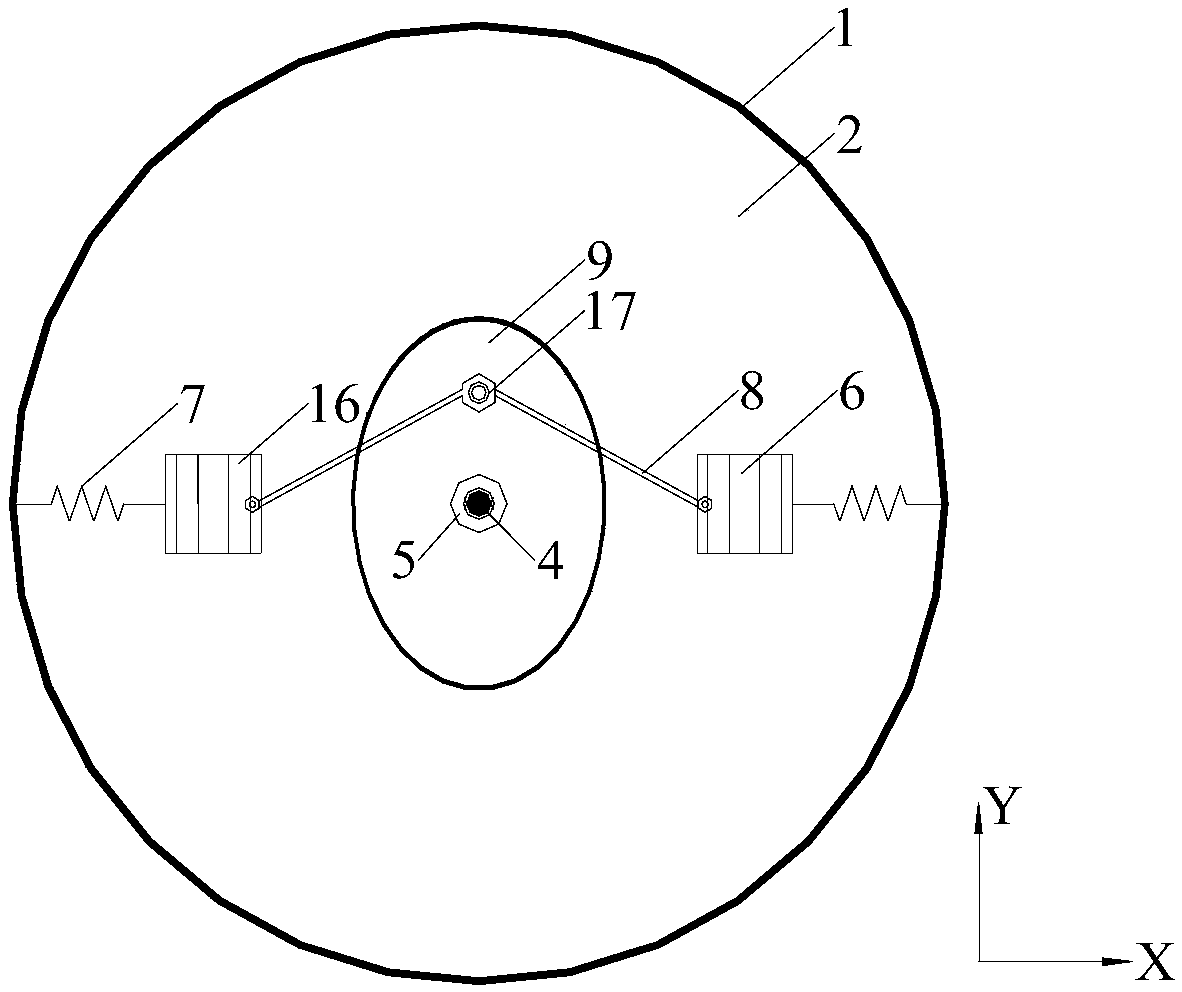

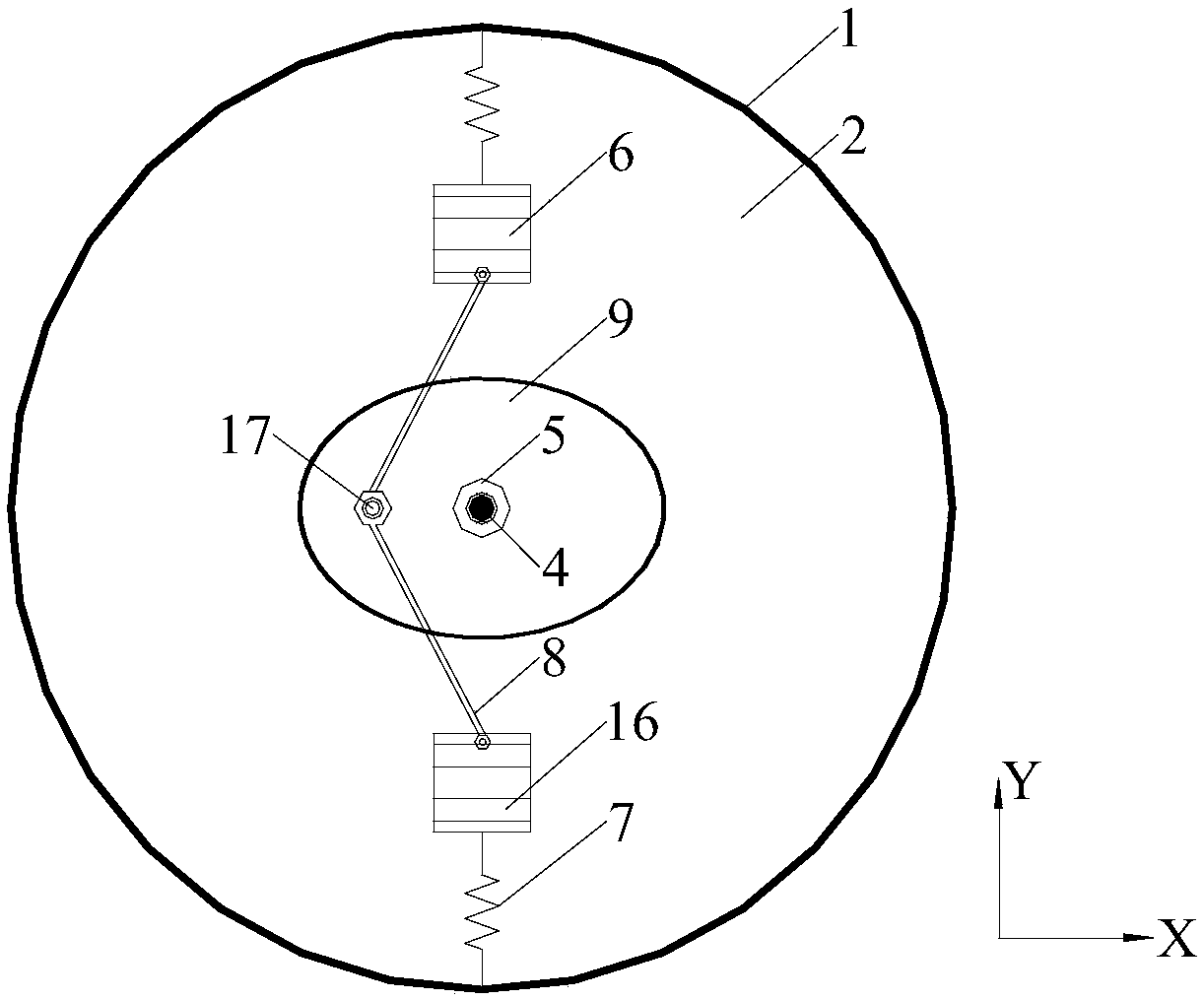

[0041] The vibration excitation layer includes two mass blocks. A roller is arranged at the bottom of the mass blocks. One end of the mass blocks is connected to the inner wall of the barrel by a spring, and the oth...

Embodiment 2

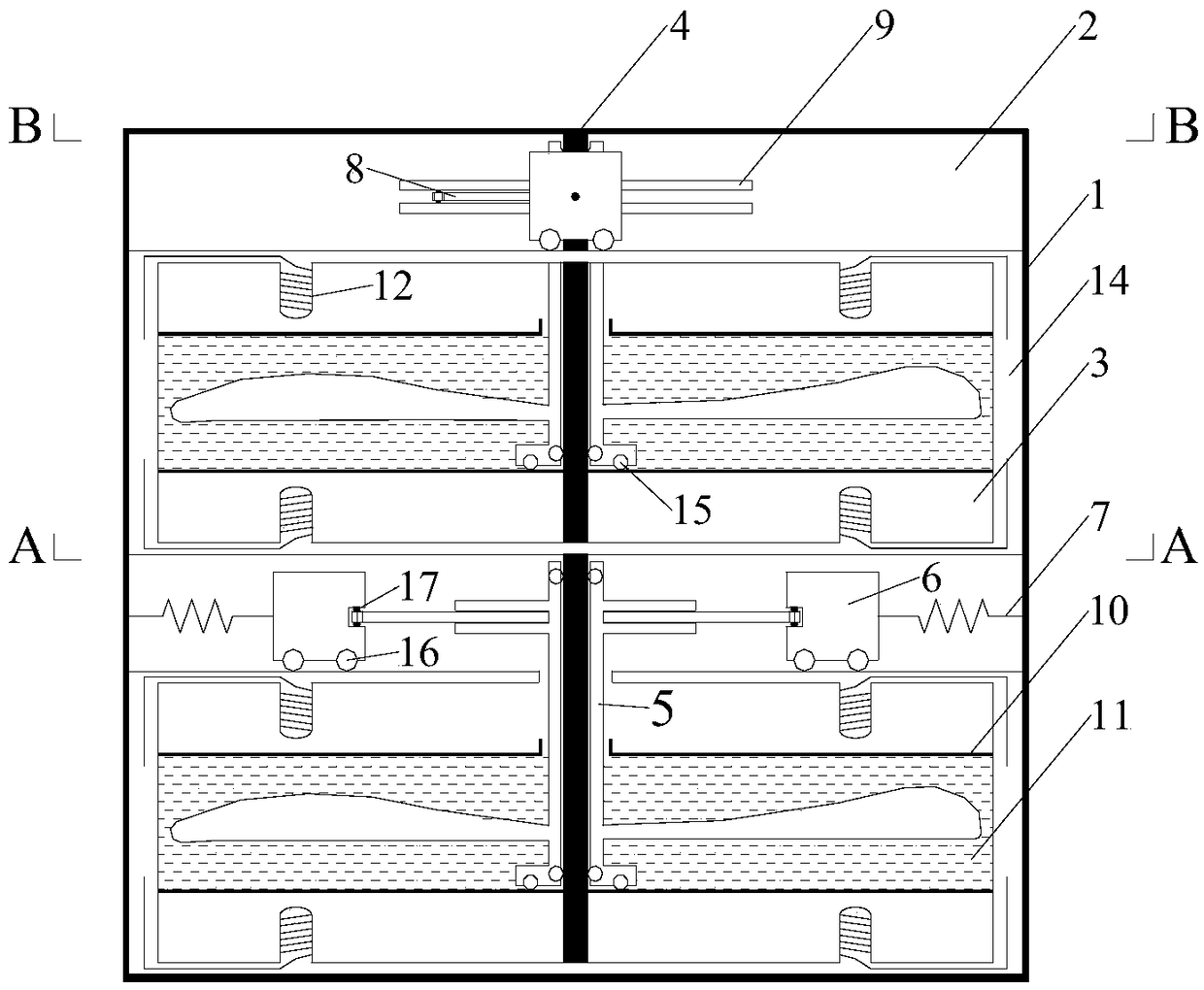

[0048] like figure 1 As shown, the rotary adaptive magnetorheological fluid shock absorber includes two layers. There are two vibration excitation layers 2 and two magnetorheological damping layers 3 respectively. The vibration excitation layer 2 and the magnetorheological damping layer 3 mainly control the vibration in the Y direction, the lower layer mainly controls the vibration in the X direction, and the vibration excitation layer 2 that controls vibration in the same direction is above the magnetorheological damping layer 3, and the circuit control room 13 It is only distributed inside the magnetorheological damping layer 3 .

[0049] Specifically, it includes a cylinder 1, and the cylinder 1 is divided into an upper part and a lower part; the upper part includes a vibration excitation layer 2 and a magnetorheological damping layer 3; the lower part also includes a vibration excitation layer 2 and a magnetorheological damping layer 3;

[0050] A full-length fixed shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com